High-concentration anion-doped TiO2 as well as preparation method and application thereof

An anion, high-concentration technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of uncontrollable doping amount, low doping amount, high energy consumption, etc., achieve simple operation, increase electronic conductivity, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

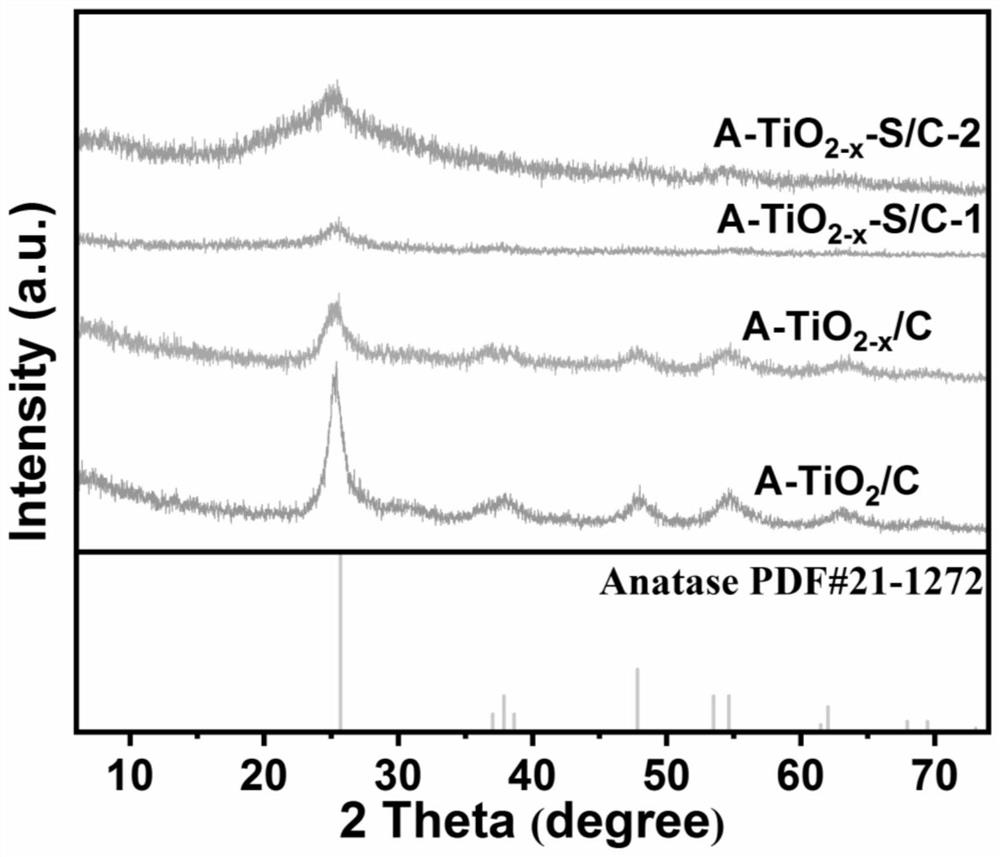

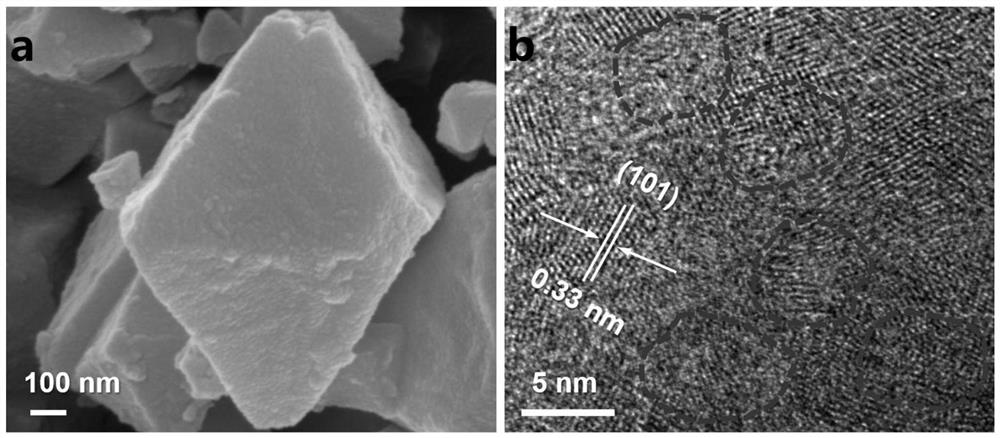

[0038] 2-NH 2-The MIL-125 precursor was placed in a porcelain boat and heated to 400°C in a muffle furnace at a heating rate of 5°C / min for pre-carbonization for 2h; 2 Heating to 600°C at a heating rate of 10°C / min in a mixed atmosphere of Ar / Ar (hydrogen gas fraction is 5%), and reacting at a constant temperature for 2 hours; after naturally cooling to room temperature, black titanium dioxide powder rich in oxygen vacancies was collected; porcelain boat Put 1.0 g of sublimated sulfur powder into the tube furnace, put the sublimed sulfur in the upper atmosphere port of the tube furnace, and place the black titanium dioxide sample in the lower atmosphere port. In the argon protective gas, the temperature is raised to 500 °C at a heating rate of 10 °C / min, and the temperature is constant for 2 hour; after the reaction was completed, cool to room temperature, and use carbon disulfide (CS 2 ) and deionized (DI) water to remove excess S, and vacuum-dried at 65 °C to obtain high-co...

Embodiment 2

[0044] 2-NH 2 -The MIL-125 precursor was placed in a porcelain boat, heated in a muffle furnace at a heating rate of 5°C / min to 400°C for pre-carbonization for 2h; 2 Heating to 600°C at a heating rate of 10°C / min in a mixed atmosphere of Ar / Ar (hydrogen gas fraction is 5%), and reacting at a constant temperature for 2 hours; after naturally cooling to room temperature, black titanium dioxide powder rich in oxygen vacancies was collected; porcelain boat Put 1.0 g of red phosphorus powder into the tube furnace. The red phosphorus powder is placed in the upper atmosphere port of the tube furnace, and the black titanium dioxide sample is placed in the lower atmosphere port. 2 hours; after the completion of the reaction, cool to room temperature, and use phosphorus tribromide (PBr 3 ) and deionized (DI) water to remove excess phosphorus powder, and vacuum-dried at 65 °C to obtain high-concentration phosphorus-doped titanium dioxide. The resulting phosphorus-doped titanium dioxide...

Embodiment 3

[0046] The anatase precursor was placed in a porcelain boat and heated to 400 °C in a muffle furnace at a heating rate of 5 °C / min for pre-carbonization for 2 h; 2 Heating to 600°C at a heating rate of 10°C / min in a mixed atmosphere of Ar / Ar (hydrogen gas fraction is 5%), and reacting at a constant temperature for 2 hours; after naturally cooling to room temperature, black titanium dioxide powder rich in oxygen vacancies was collected; porcelain boat Put 1.0 g of selenium powder into the tube furnace, place the selenium powder in the upper atmosphere port of the tube furnace, and place the black titanium dioxide sample in the lower atmosphere port. In the argon protective gas, raise the temperature to 500 °C at a heating rate of 10 °C / min, and keep the temperature for 2 hours. ; After the completion of the reaction, cool to room temperature, and use carbon disulfide (CS 2 ) and deionized (DI) water to remove excess elemental selenium, and vacuum-dried at 65 °C to obtain high-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com