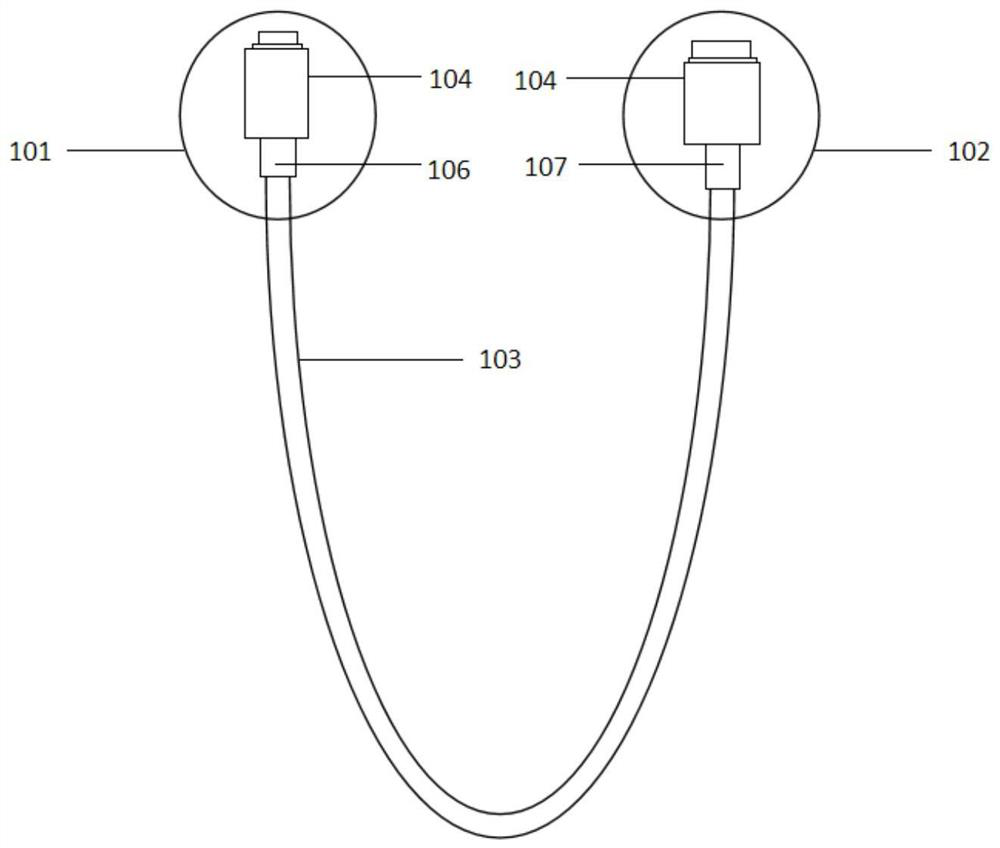

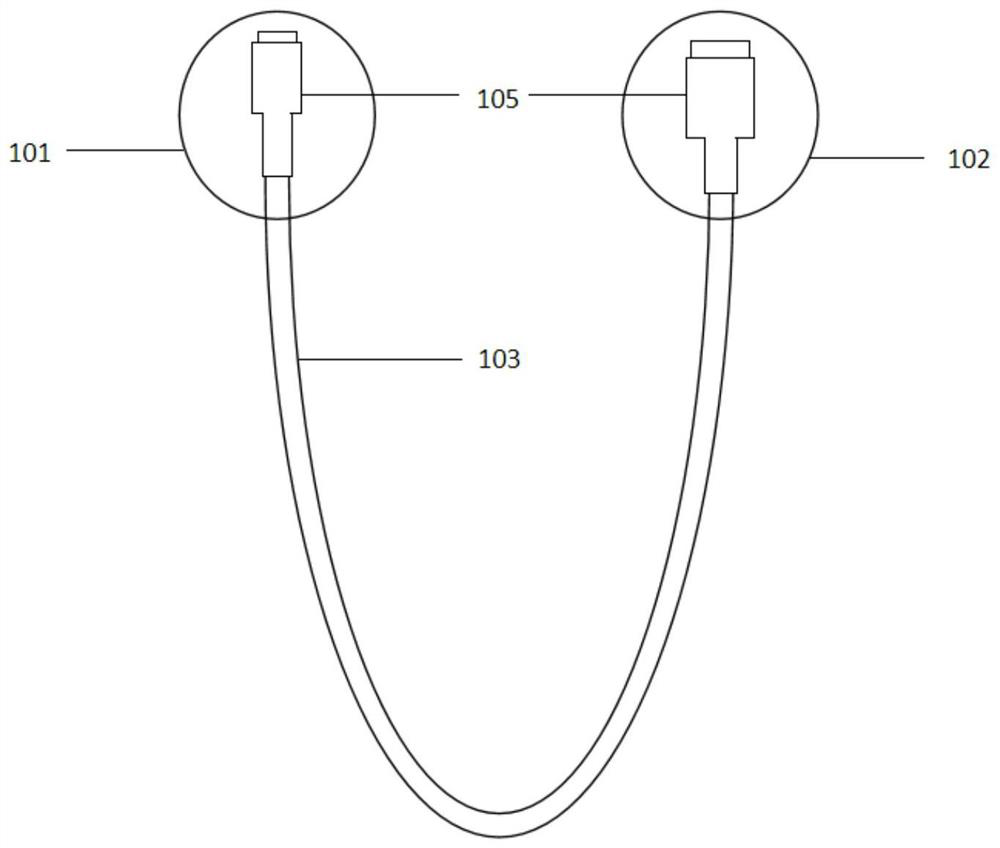

High-tension-bearing data line and preparation method thereof

A data line, high-tension technology, applied in the field of data lines, can solve problems affecting the normal use of data lines, loose welding points, exposed cores, etc., to achieve good elasticity, not easy to break, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

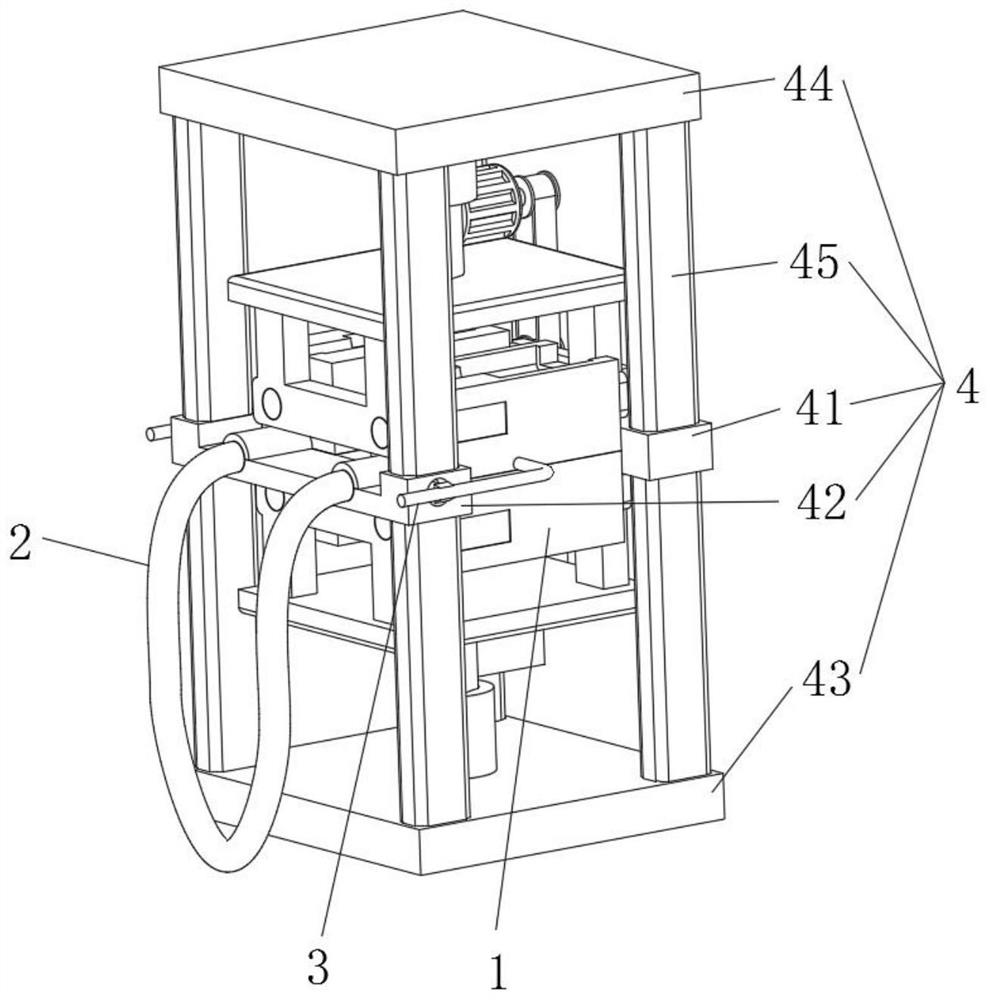

Method used

Image

Examples

Embodiment 1

[0058] The inner mold material of the data line connector is prepared from the following raw materials in parts by mass: 80 parts of ABS, 30 parts of PC, 30 parts of TPV, 20 parts of stearic acid, 1 part of antioxidant 1076, and ultraviolet absorber UV-326 1 part, 2.5 parts of KH550 modified graphene oxide, 1.5 parts of piperazine pyrophosphate, 3 parts of magnesium hydroxide powder, 1 part of antistatic agent HKD 5101, 10 parts of maleic anhydride grafted ABS (ABS-g-MAH).

[0059] The preparation steps of the inner mold material of the data line connector are as follows:

[0060] 1) Crushing ABS, PC, TPV;

[0061] 2) Stearic acid and crushed ABS, PC, TPV and maleic anhydride grafted ABS are heated in a mixer and premixed until uniformly mixed;

[0062] 3) Add antioxidant 1076, ultraviolet absorber UV-326, KH550 modified graphene oxide, piperazine pyrophosphate, magnesium hydroxide powder, antistatic agent HKD 510 into the mixer, and mix evenly again;

[0063] 4) Place the m...

Embodiment 2

[0069] The inner mold material of the data line connector is prepared from the following raw materials in parts by mass: 50 parts of ABS, 50 parts of PC, 50 parts of TPV, 10 parts of zinc stearate, 0.5 parts of antioxidant 1076, and ultraviolet absorber UV-326 0.5 parts, KH560 modified graphene oxide 0.5 parts, piperazine pyrophosphate 1 part, magnesium hydroxide powder 2 parts, antistatic agent HKD 5100.5 parts, maleic anhydride grafted ABS (ABS-g-MAH) 5 parts.

[0070] The preparation steps of the inner mold material of the data line connector are as follows:

[0071] 1) Crushing ABS, PC, TPV;

[0072] 2) pre-mixing zinc stearate and crushed ABS, PC, TPV and maleic anhydride grafted ABS in a mixer by heating and raising the temperature until uniformly mixed;

[0073] 3) Add antioxidant 1076, ultraviolet absorber UV-326, KH560 modified graphene oxide, piperazine pyrophosphate, magnesium hydroxide powder, antistatic agent HKD 510 into the mixer, and mix evenly again;

[0074...

Embodiment 3

[0077] The inner mold material of the data line connector is prepared from the following raw materials in parts by mass: 65 parts of ABS, 40 parts of PC, 40 parts of TPV, 15 parts of calcium stearate, 1.5 parts of antioxidant 1076, and ultraviolet absorber UV-326 1.5 parts, KH570 modified graphene oxide 1.5 parts, piperazine pyrophosphate 0.5 parts, magnesium hydroxide powder 1 part, antistatic agent HKD 5101.5 parts, maleic anhydride grafted ABS (ABS-g-MAH) 7.5 parts.

[0078] The preparation steps of the inner mold material of the data line connector are as follows:

[0079] 1) Crushing ABS, PC, TPV;

[0080] 2) Calcium stearate and crushed ABS, PC, TPV and maleic anhydride grafted ABS are heated in a mixer and premixed until uniformly mixed;

[0081] 3) Add antioxidant 1076, ultraviolet absorber UV-326, KH570 modified graphene oxide, piperazine pyrophosphate, magnesium hydroxide powder, antistatic agent HKD 510 into the mixer, and mix evenly again;

[0082] 4) Place the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com