Sealant composition, polyurethane sealant and preparation method of polyurethane sealant

A technology of polyurethane sealant and composition, applied in the field of sealant, can solve the problems of increased cost and energy consumption, inconvenient storage, transportation and processing, poor compatibility of glass microbeads, etc., so as to reduce labor costs and construction strength, and reduce production. and transportation costs, the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

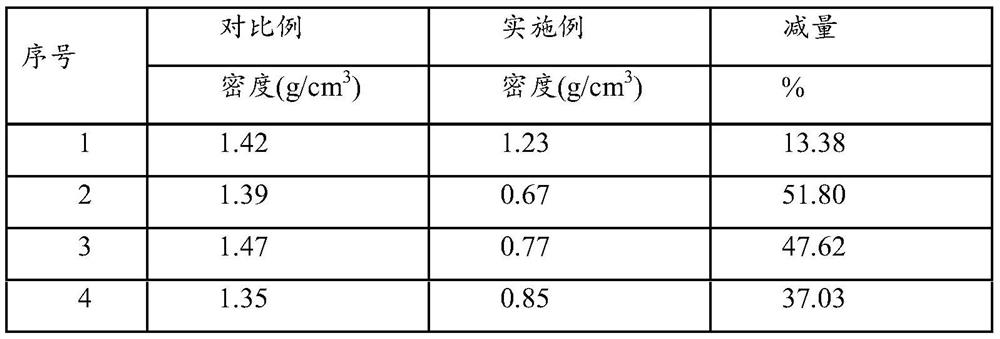

Examples

preparation example Construction

[0022] The embodiment of the present application provides a preparation method of polyurethane sealant, comprising the following steps:

[0023] Step 1, put 80-100 parts of polyether polyol at 100-110 ° C, dehydrate under reduced pressure for 2 hours in a vacuum of 0.1 MPa, cool to 60 ° C, then add 10-20 parts of isocyanate and 0.01-0.1 parts of prepolymerization The temperature of the bulk catalyst is raised to 80-90° C., and the reaction is carried out for 5-8 hours to obtain a prepolymer. The polyether polyol is a polyether polyol or a mixture of polyether polyols with a weight average molecular weight (Mw) of 2000-7000. The function of the prepolymer catalyst is to catalyze the addition polymerization reaction when synthesizing the polyurethane prepolymer. The prepolymer catalyst is stannous octoate, stannous octoate dibutyltin laurate, triethylenediamine, bismorpholine diethyl, triethylamine, dibutyltin dichloride, butyl stannous octoate, tetramethylbutyl any of the diam...

Embodiment 1

[0038] Step 1, dehydrate 89.7 parts of polyoxypropylene-oxyethylene triol (Mw=7000) at 110°C for 2 hours under vacuum at 0.1 MPa, cool to 60°C, add 10.3 parts of diphenylmethane diisocyanate and 0.01 part of octanoic acid The stannous temperature was raised to 90°C, and the reaction was carried out for 5 hours to obtain a prepolymer.

[0039] Step 2: Stir 100 parts of calcium carbonate at 90°C for 15 minutes at high speed, add 0.1 part of oleic acid, and continue stirring for 30 minutes to obtain modified calcium carbonate.

[0040] Step 3, 35 parts of the above-mentioned prepolymer, 35 parts of modified calcium carbonate, 0.1 part of expanded microspheres, 5 parts of diisononyl phthalate and 0.1 part of fumed silica are added to the planetary dynamic mixer, and the vacuum Stir at 0.1MPa for 0.5h, then add 0.01 part of alkylsulfonic acid isocyanate and 0.2 part of dioctyltin dilaurate, and stir for 30min at a vacuum of 0.1MPa to obtain a low-density one-component polyurethane ...

Embodiment 2

[0046] Step 1, 45.7 parts of polyoxypropylene diol (Mw=2000) and 34.5 parts of polyoxypropylene triol (Mw=3000) were dehydrated under reduced pressure at 110 ° C for 2 hours at a vacuum degree of 0.1 MPa, cooled to 60 ° C, and 14.8 parts of toluene were added Diisocyanate and 0.05 parts of stannous octoate are heated to 80°C and reacted for 8 hours to obtain a prepolymer.

[0047] Step 2: Stir 100 parts of calcium carbonate / kaolin at 70°C for 10 minutes at high speed, add 1 part of stearic acid, and continue stirring for 30 minutes to obtain modified calcium carbonate / kaolin.

[0048] Step 3, 65 parts of above-mentioned prepolymers, 20 parts of modified calcium carbonate, 10 parts of modified kaolin, 2 parts of expanded microspheres, 25 parts of epoxy soybean oil and 5 parts of fumed silica are added in the planetary dynamic mixer, Stir at a vacuum of 0.1 MPa for 1.5 hours, then add 0.5 parts of alkylsulfonic acid isocyanate and 0.5 parts of dibutyltin dilaurate, and stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com