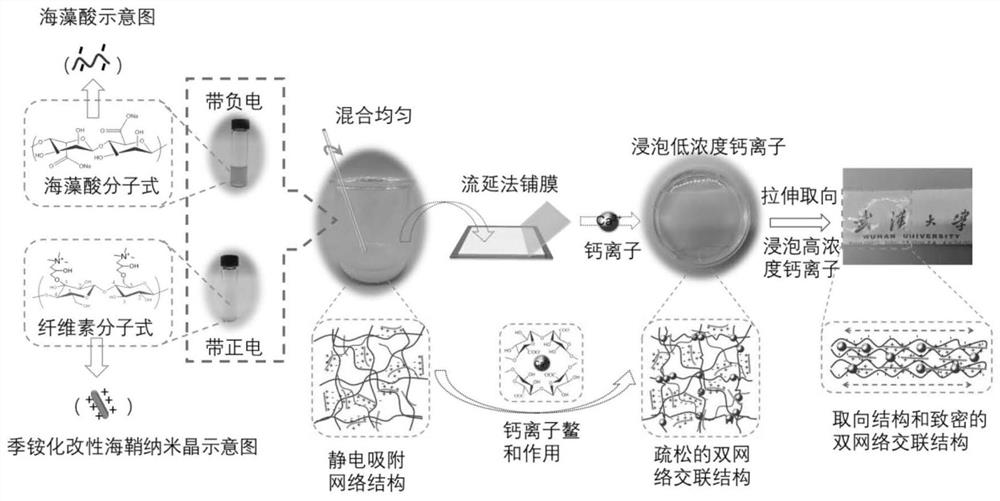

Preparation method of high-strength nanocellulose/alginic acid composite hydrogel

A nanocellulose and composite hydrogel technology, applied in the field of polymer functional materials, can solve the problems of poor mechanical properties of sodium alginate hydrogel, difficult to meet practical application requirements, low stiffness and strength, etc., and achieve environmental friendliness. performance, excellent enhancement effects, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

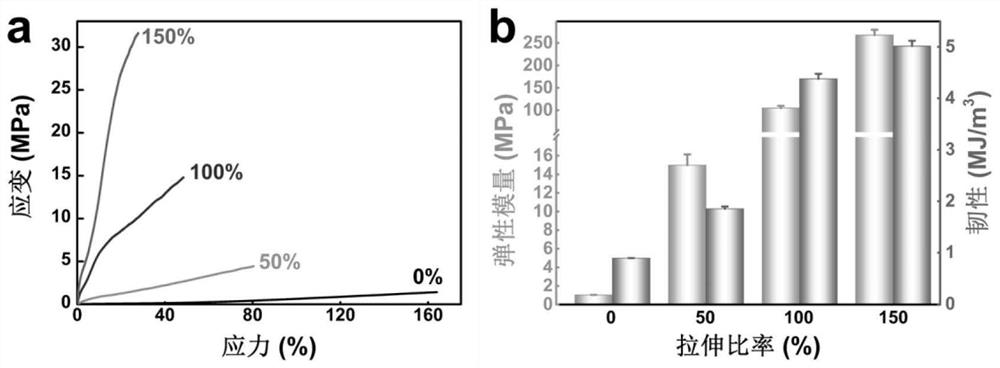

Embodiment 1

[0021] (1) hydrochloric acid is hydrolyzed to obtain sea sheath nanocrystals. The specific process is: 200 ml of water to 100 ml of concentrated hydrochloric acid (12 m), resulting in a 300 mL of 4M hydrochloric acid solution, poured into a three flask, heat the oil bath heating to 100 ° C, with a condensation reflow device and a stirring paddle, 7.5g sea sheel Cellulose (dry weight) is added to the three flask, and the reaction is stirred at 300 rpm for 4 h. After the reaction, the reaction after the reaction is diluted to 2L, stand overnight, after the settlement, remove the supernatant, leave a clean liquid , Centrifuge 7000 rpm of the underwater liquid is 15 min, pour it off, and the precipitate in the centrifugal tube is stirred well, then centrifuge again at 7000 rpm for 15 min, pour it off the supernatant, and put the incision liquid into the dialysis bag (interception molecular weight In the 8000-14000), in ultrapure water, three days, centrifuge at 1500 rpm 10min, take th...

Embodiment 2

[0027] (1) hydrochloric acid is hydrolyzed to obtain sea sheath nanocrystals. The specific process is: 200 ml of water to 100 ml of concentrated hydrochloric acid (12 m), resulting in a 300 mL of 4M hydrochloric acid solution, poured into a three flask, heat the oil bath heating to 100 ° C, with a condensation reflow device and a stirring paddle, 7.5g sea sheel Cellulose (dry weight) is added to the three flask, and the reaction is stirred at 300 rpm for 4 h. After the reaction, the reaction after the reaction is diluted to 2L, stand overnight, after the settlement, remove the supernatant, leave a clean liquid , Centrifuge 7000 rpm of the underwater liquid is 15 min, pour it off, and the precipitate in the centrifugal tube is stirred well, then centrifuge again at 7000 rpm for 15 min, pour it off the supernatant, and put the incision liquid into the dialysis bag (interception molecular weight In the 8000-14000), in ultrapure water, three days, centrifuge at 1500 rpm 10min, take th...

Embodiment 3

[0033] (1) hydrochloric acid is hydrolyzed to obtain sea sheath nanocrystals. The specific process is: 200 ml of water to 100 ml of concentrated hydrochloric acid (12 m), resulting in a 300 mL of 4M hydrochloric acid solution, poured into a three flask, heat the oil bath heating to 100 ° C, with a condensation reflow device and a stirring paddle, 7.5g sea sheel Cellulose (dry weight) is added to the three flask, and the reaction is stirred at 300 rpm for 4 h. After the reaction, the reaction after the reaction is diluted to 2L, stand overnight, after the settlement, remove the supernatant, leave a clean liquid , Centrifuge 7000 rpm of the underwater liquid is 15 min, pour it off, and the precipitate in the centrifugal tube is stirred well, then centrifuge again at 7000 rpm for 15 min, pour it off the supernatant, and put the incision liquid into the dialysis bag (interception molecular weight In the 8000-14000), in ultrapure water, three days, centrifuge at 1500 rpm 10min, take th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com