Preparation method and application of immobilized cells for mannose production

A technology for immobilizing cells and mannose, which is applied in the field of bioengineering and mannose production and preparation, can solve the problems of high mannose production cost, low enzyme recovery utilization rate, cumbersome production steps, etc., and achieve simple immobilization process, effective It is beneficial to separation and purification, and the effect of simplifying the production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

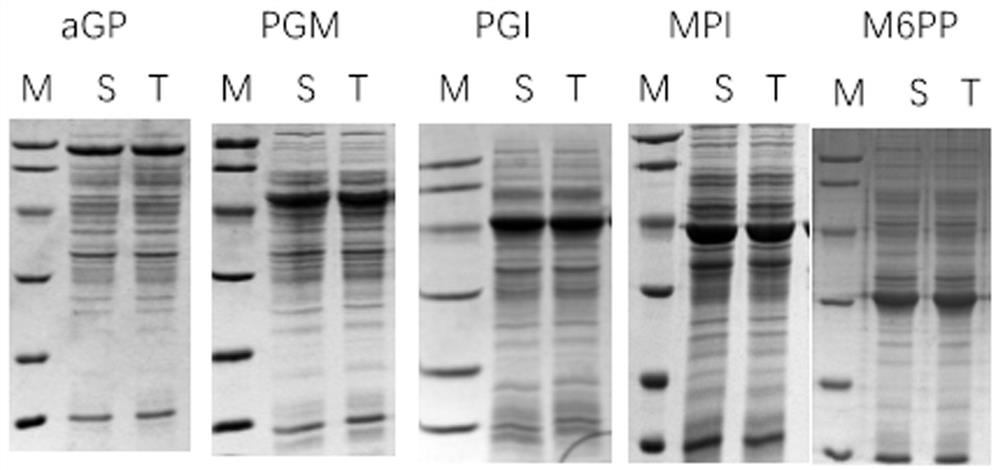

[0039] Embodiment 1: the preparation of the Bacillus subtilis fermented liquid expressing enzyme

[0040] (1) Construction of pMA5-Pylb-aGP

[0041] In this example, the agp sequence (NCBI-ProteinID: BAD85595), the gene encoding thermostable a-glucan phosphorylase, was synthesized by Suzhou Jinweizhi Biotechnology Co., Ltd. and spliced into a common plasmid. The thermostable α-glucan phosphorylase gene agp gene was obtained by PCR using a pair of primers (1-IF and 1-IR). The linear backbone of pMA5‐Pylb was obtained by PCR using a pair of primers (1-VF and 1-VR). The thermostable α-glucan phosphorylase gene fragment and the pMA5-Pylb vector backbone were then assembled using POE-PCR. The ligation product was transferred into competent SCK6 by the calcium chloride method, and the transformant was selected for colony PCR, double enzyme digestion identification and sequencing verification to obtain an expression vector, which was named pMA5-Pylb-aGP.

[0042] 1-IF: AGAAACAAC...

Embodiment 2

[0072] Embodiment 2: Production of mannose by immobilized Bacillus subtilis

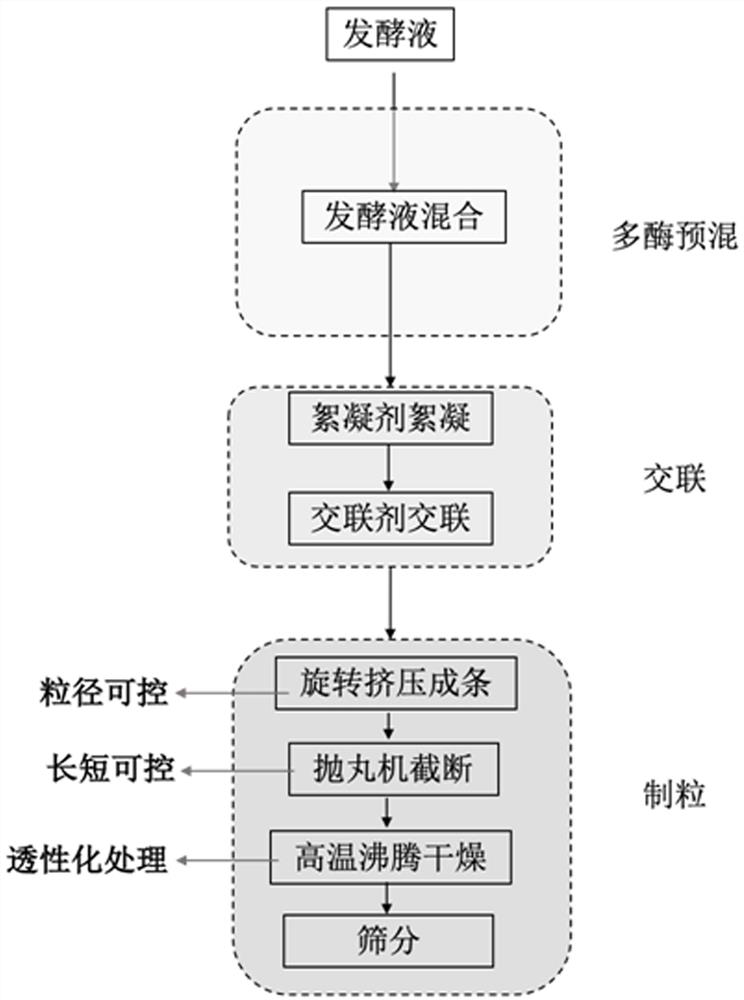

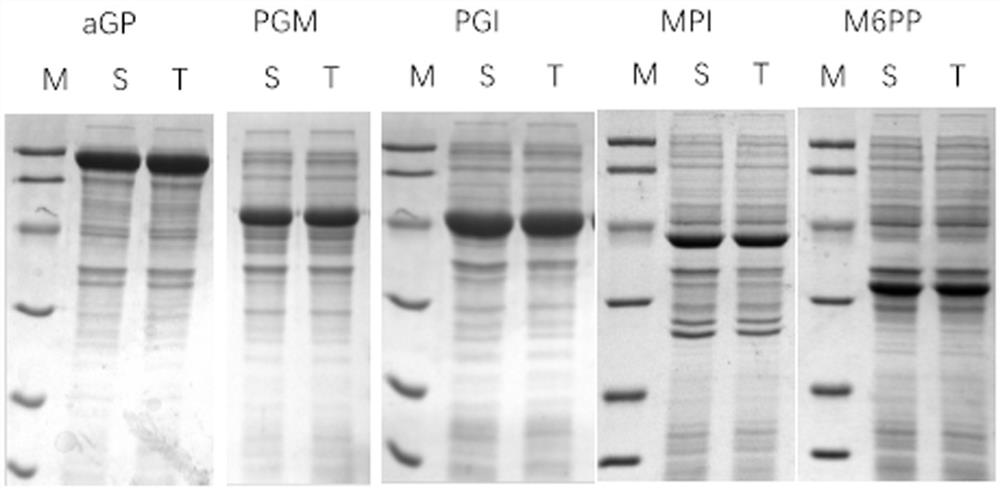

[0073] According to the OD600 ratio of 1:1:1:1:1, the Bacillus subtilis fermentation broth expressing thermostable α-glucan phosphorylase prepared in Example 1 and the Bacillus subtilis expressing thermostable glucose phosphomutase were fermented subtilis fermentation broth expressing thermostable glucose phosphoisomerase, Bacillus subtilis fermentation broth expressing thermostable mannose 6-phosphate isomerase, fermentation broth of Bacillus subtilis expressing thermostable mannose 6-phosphate phosphatase The solution was mixed so that OD 600 = 100, and 2% w / v montmorillonite was added to the bacterial suspension, and stirred evenly. Subsequently, 1% w / v polyethyleneimine aqueous solution with a molecular weight of 600 was added to flocculate at room temperature. Then, 0.5% v / v glutaraldehyde aqueous solution was added to crosslink for 2 h at room temperature. The filter cake is obtained after va...

Embodiment 3

[0075] Embodiment 3: Production of mannose by immobilized Bacillus subtilis

[0076] According to the OD600 ratio of 1:1:1:1:1, the Bacillus subtilis fermentation broth expressing thermostable α-glucan phosphorylase prepared in Example 1 and the Bacillus subtilis expressing thermostable glucose phosphomutase were fermented subtilis fermentation broth expressing thermostable glucose phosphoisomerase, Bacillus subtilis fermentation broth expressing thermostable mannose 6-phosphate isomerase, fermentation broth of Bacillus subtilis expressing thermostable mannose 6-phosphate phosphatase The solution was mixed so that OD 600 = 100, and 5% w / v diatomaceous earth was added to the bacterial suspension, and stirred evenly. Subsequently, 0.5% w / v polyethyleneimine aqueous solution with a molecular weight of 70000 was added to flocculate at room temperature. Then, 0.5% v / v glutaraldehyde aqueous solution was added to crosslink for 2 h at room temperature. The filter cake was obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com