A kind of single crystal lead zirconate titanate thin film and its preparation and application

A technology of lead zirconate titanate and thin film, which is applied in the field of single crystal lead zirconate titanate thin film and its preparation, which can solve the problems affecting microstructure and performance, unable to thick thin film, and unable to obtain structurally controllable thin film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

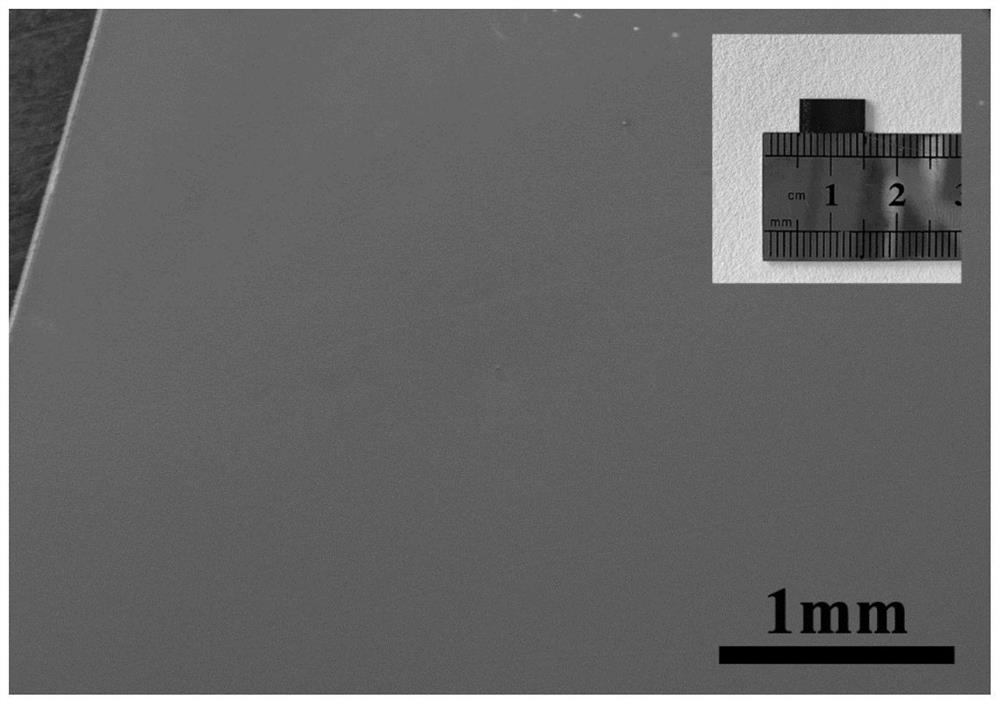

Image

Examples

Embodiment 1

[0074] 1) Weigh 0.3 mmol of zirconium oxychloride octahydrate and place it in a beaker, add 20 mL of ethylene glycol methyl ether to dissolve, and fully stir for 20 min to obtain a solution with a molar concentration of zirconium ions of 15 mmol / L;

[0075] 2) Under stirring, add 3.6mmol of lead nitrate to the solution prepared in step 1), and stir for 20 minutes until the solid is completely dissolved; then add 2.7mmol of tetra-n-butyl titanate, and stir for 10 minutes to obtain a mixed solution; , the molar ratio of the sum of zirconium and titanium elements to the lead element is 1:1.2, and the molar ratio of zirconium and titanium elements in the sum of zirconium and titanium elements is 0.1 (in terms of mole percentage, it is 10mol%);

[0076] 3) Add the mixed solution prepared in step 2) dropwise to 75ml of ammonia water (ammonia in excess), let it stand for 20min (complete precipitation); then, wash the precipitate with 50ml of deionized water, filter, repeat washing and...

Embodiment 2

[0091] 1) Weigh 0.10 mmol of zirconium oxychloride octahydrate and place it in a beaker, add 15 mL of ethylene glycol methyl ether to dissolve, and fully stir for 10 min to obtain a solution with a zirconium ion molar concentration of 6.67 mmol / L;

[0092] 2) Under stirring, add 2.4 mmol of lead nitrate to the solution prepared in step 1), fully stir for 10 minutes until the solid is completely dissolved, then add 1.90 mmol of tetra-n-butyl titanate, and stir for 10 minutes to obtain a mixed solution; Wherein, the molar ratio of the sum of zirconium and titanium elements to the lead element is 1:1.2, and the molar ratio of zirconium elements in the sum of zirconium and titanium elements is 0.05 (5mol% in mole percent);

[0093] 3) Add the mixed solution prepared in step 2) dropwise to 50ml ammonia water (excess ammonia water), let it stand for 20min (complete precipitation); then, wash the precipitate with 50ml deionized water, filter, repeat washing and filtering 5 times , to...

Embodiment 3

[0116] 1) Weigh 0.7 mmol of zirconium oxychloride octahydrate and place it in a beaker, add 20 mL of ethylene glycol methyl ether to dissolve, and fully stir for 20 min to obtain a solution with a molar concentration of zirconium ions of 35 mmol / L;

[0117] 2) Under stirring, add 5.25 mmol of lead nitrate to the solution prepared in step 1), fully stir for 20 minutes until the solid is completely dissolved, then add 2.8 mmol of tetra-n-butyl titanate, and stir for 10 minutes to obtain a mixed solution; Wherein, the molar ratio of the sum of zirconium and titanium elements to the lead element is 1:1.5, and the molar ratio of zirconium elements in the sum of zirconium and titanium elements is 0.2 (20mol% in mole percent);

[0118] 3) Add the mixed solution prepared in step 2) dropwise to 100ml ammonia water (ammonia water is excessive), let it stand for 20min (complete precipitation); then, wash the precipitate with 50ml deionized water, filter, repeat washing and filtering 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com