W-TiO2 monatomic supported photocatalyst and preparation method thereof

A photocatalyst and atomic technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst, etc., can solve problems affecting photocatalytic stability, etc., and achieve the effect of improving photocatalytic activity, low cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

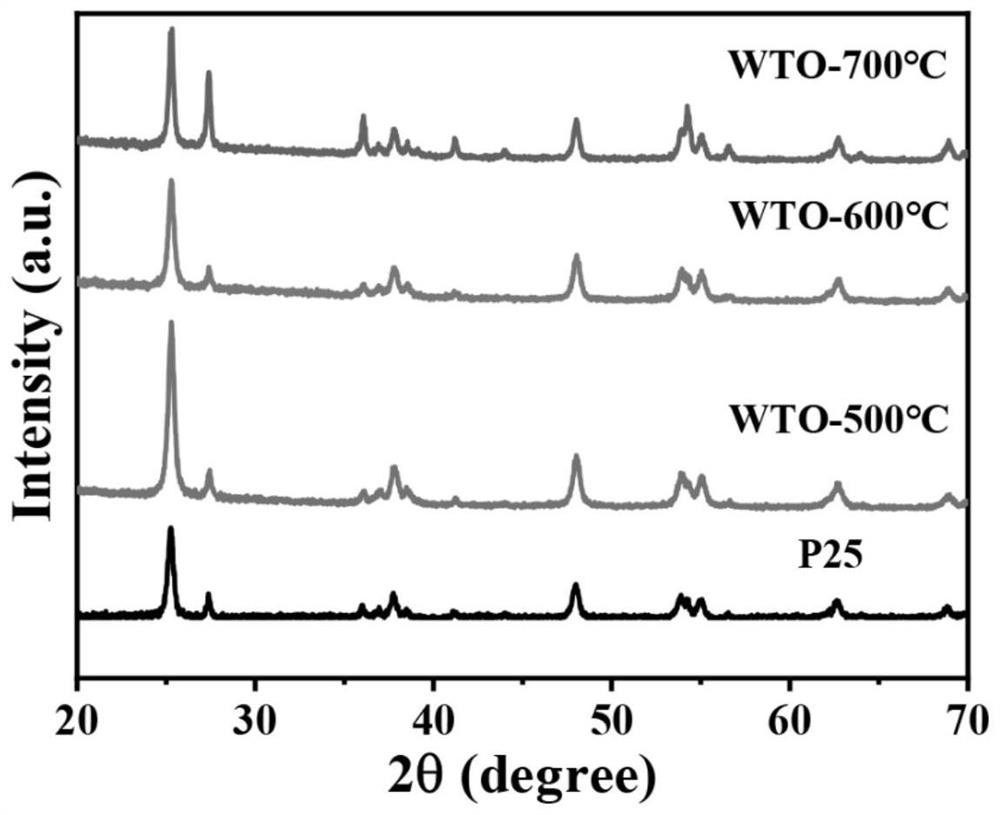

[0024] A kind of W-TiO 2 The preparation method of single atom supported photocatalyst comprises the steps:

[0025] S100: Weigh TiO according to the mass ratio of 10:1 2 and tungsten hexacarbonyl, and put them in a mortar, mix them thoroughly to get a well-mixed mixture, and then seal the mixture in a vacuum quartz tube

[0026] S200: Place the sealed vacuum quartz tube containing the mixture in a box-type resistance furnace, raise the temperature of the box-type resistance furnace to 80°C at a heating rate of 5°C / min to sublimate tungsten hexacarbonyl, and then keep the temperature at 80°C Keep for 1h;

[0027] S300: Continue to heat up to 500°C at a heating rate of 2-5°C / min, calcining for 2 hours, wait for the resistance furnace to cool down to room temperature, and then take out the vacuum quartz tube, and then obtain a blue powder;

[0028] S400: wash the blue powder with deionized water 2 to 3 times, and dry at 60°C to obtain W-TiO 2 Single atom supported photocatal...

Embodiment 2

[0030] A kind of W-TiO 2 The preparation method of single atom supported photocatalyst comprises the steps:

[0031] S100: Weigh TiO according to the mass ratio of 10:1 2 and tungsten hexacarbonyl, and put them in a mortar, mix them thoroughly to get a well-mixed mixture, and then seal the mixture in a vacuum quartz tube

[0032] S200: Place the sealed vacuum quartz tube containing the mixture in a box-type resistance furnace, raise the temperature of the box-type resistance furnace to 80°C at a heating rate of 5°C / min to sublimate tungsten hexacarbonyl, and then keep the temperature at 80°C Keep for 1h;

[0033] S300: Continue to heat up to 600°C at a heating rate of 2-5°C / min, calcining for 2 hours, wait for the resistance furnace to cool down to room temperature, and then take out the vacuum quartz tube, and then obtain a blue powder;

[0034] S400: wash the blue powder with deionized water 2 to 3 times, and dry at 60°C to obtain W-TiO 2 Single atom supported photocatal...

Embodiment 3

[0036] A kind of W-TiO 2 The preparation method of single atom supported photocatalyst comprises the steps:

[0037] S100: Weigh TiO according to the mass ratio of 10:1 2 and tungsten hexacarbonyl, and put them in a mortar, mix them thoroughly to get a well-mixed mixture, and then seal the mixture in a vacuum quartz tube

[0038] S200: Place the sealed vacuum quartz tube containing the mixture in a box-type resistance furnace, raise the temperature of the box-type resistance furnace to 80°C at a heating rate of 5°C / min to sublimate tungsten hexacarbonyl, and then keep the temperature at 80°C Keep for 1h;

[0039] S300: Continue to heat up to 700°C at a heating rate of 2-5°C / min, calcining for 2 hours, wait for the resistance furnace to cool down to room temperature, and then take out the vacuum quartz tube, and then obtain a blue powder;

[0040] S400: wash the blue powder with deionized water 2 to 3 times, and dry at 60°C to obtain W-TiO 2 Single atom supported photocatal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com