Preparation method and equipment of efficient composite photocatalyst

A composite photocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult precise control of reaction conditions, recombination of photogenerated electrons and holes, slow charge transfer efficiency, etc. , to achieve the effects of improving photocatalytic performance, inhibiting recombination, and enhancing photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0074] RGO / MoS 2 / TiO 2 The preparation of efficient composite photocatalyst (adopting the equipment that specific embodiment 1 provides), comprises the following steps:

[0075] (1) TiO 2 preparation;

[0076] (2)MoS 2 preparation;

[0077] (3) Preparation of TiO 2 / MoS 2 ;

[0078] (4) Take the GO solution, ultrasonically make it into a uniformly dispersed solution, and add the TiO obtained in step (3) 2 / MoS 2 Composite materials, ultrasonically disperse them evenly;

[0079] (5) The uniformly dispersed solution obtained in step (4) is transferred to an autoclave, heated for reaction, and cooled to room temperature;

[0080] (6) Wash, dry and grind the product of step (5) to obtain RGO / MoS 2 / TiO 2 High-efficiency composite photocatalyst.

[0081] The concentration of GO solution described in step (4) is 4mg·mL -1 , Ultrasonic time is 20min and 2h respectively.

[0082] Step (1) includes:

[0083] 1) Take absolute ethanol, glacial acetic acid, and distilled ...

specific Embodiment approach 2

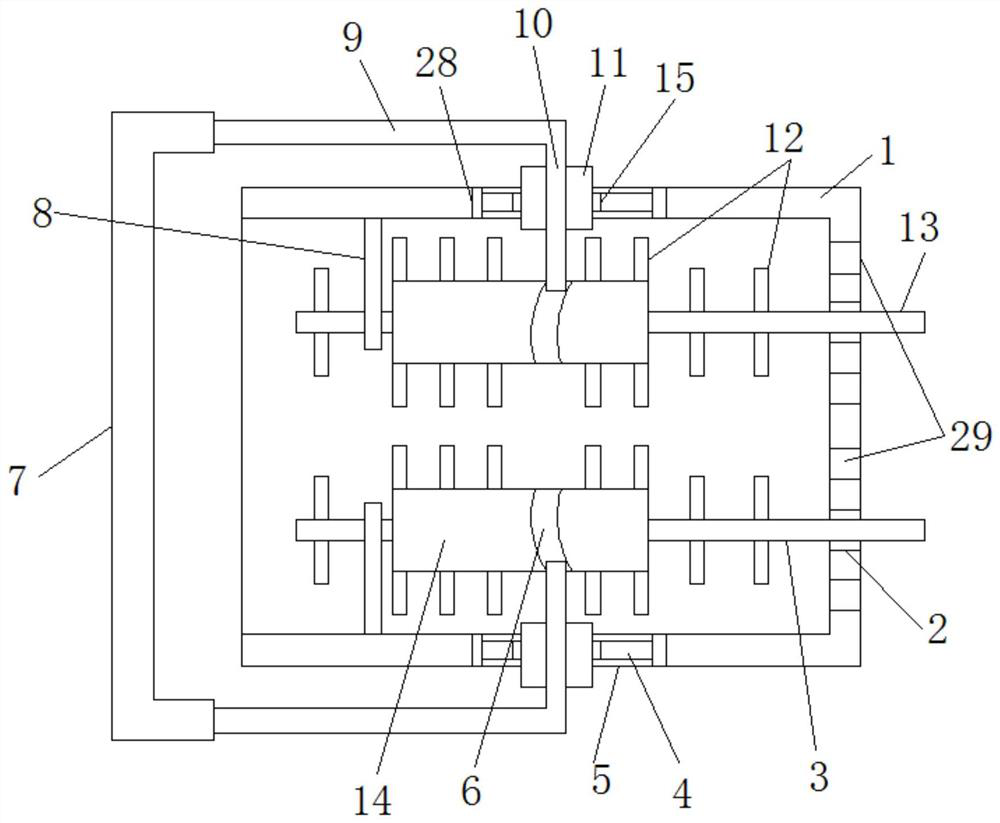

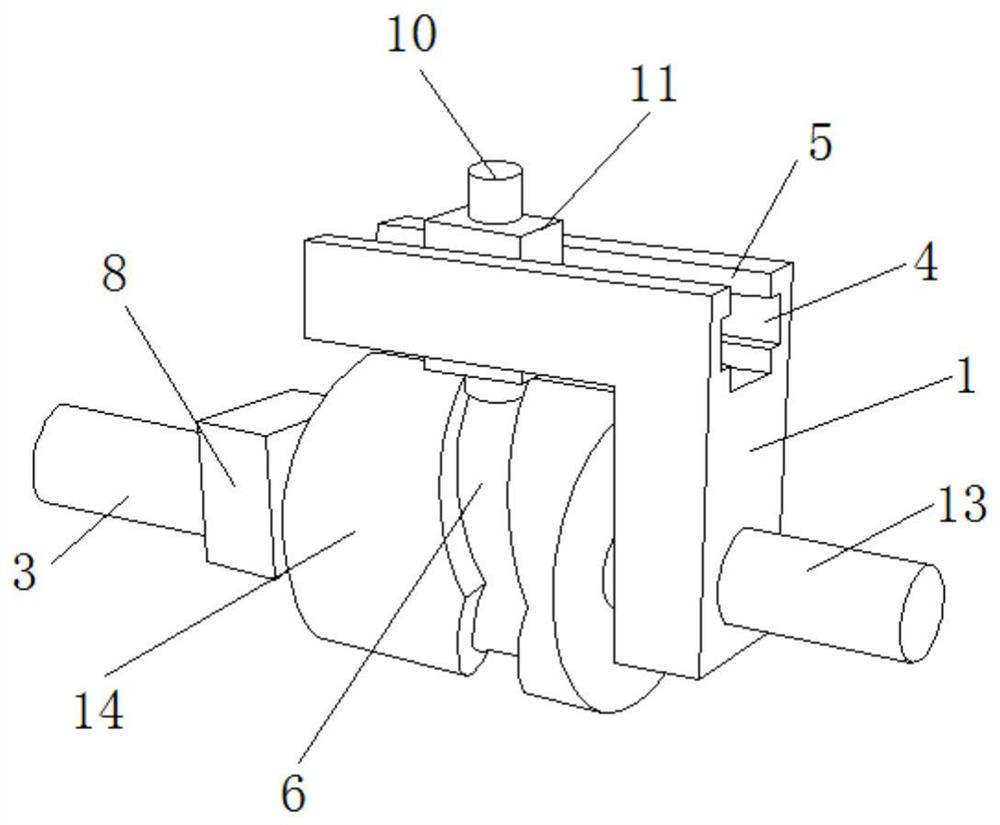

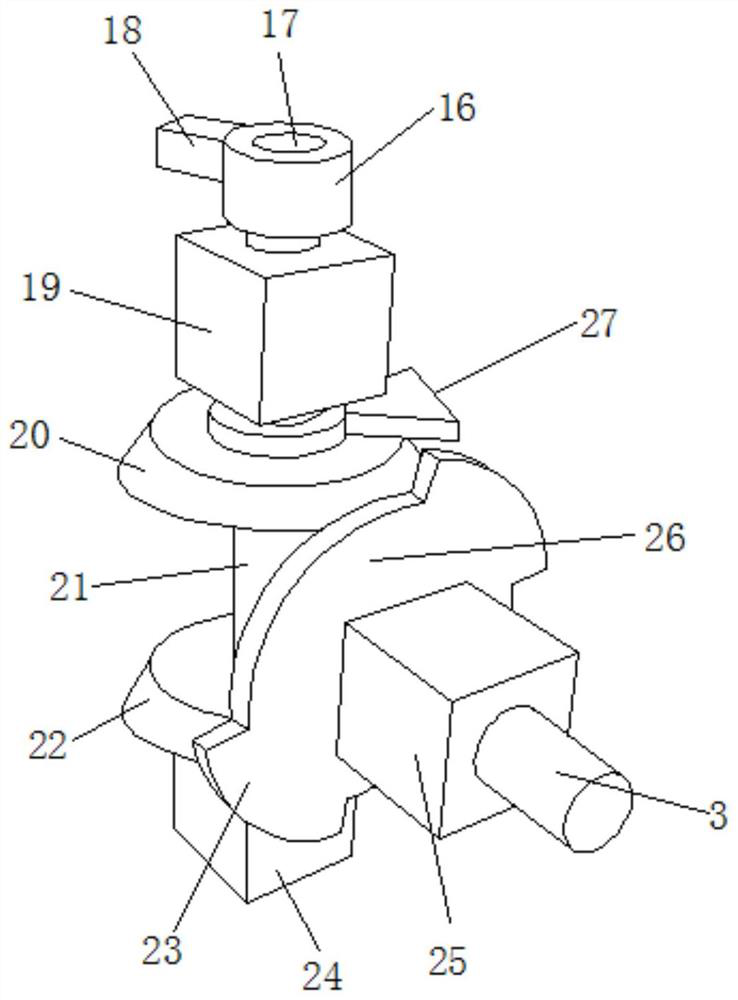

[0105] In one embodiment, such as Figure 1-5 As shown, the RGO / MoS provided by the present invention 2 / TiO 2 The preparation equipment of high-efficiency composite photocatalyst: comprise: microwave synthesis reaction device, described microwave synthesis reaction device is used to carry out continuous microwave synthesis to the uniformly dispersed solution that described step (4) obtains; Described microwave synthesis reaction device is microwave generator;

[0106] The microwave synthesis reaction device includes a reaction barrel and a microwave synthesis device, the microwave synthesis device is located in the reaction barrel, the microwave synthesis device is provided with a start switch, and the start switch is located on the outer wall of the reaction barrel.

[0107] In this embodiment, when the catalyst needs to be prepared, the uniformly dispersed solution obtained in the step (4) is sequentially injected into the reaction barrel, and by starting the start switch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com