Method for recycling waste acid residue resources generated in stainless steel industry

A stainless steel and industry technology, applied in the field of waste acid slag resource recycling generated by the stainless steel industry, can solve the problems of large processing capacity, low processing cost, and reducing the difficulty and cost of waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A resource for the stainless steel industry waste acid produced slag recycling method, comprising the steps of:

[0036] S1, the stainless steel washing waste, that is, the waste acid residue generated by the stainless steel industry, and feed into aerated stirring rinsing apparatus, and water is added;

[0037] S2, after the rinsing ends, solid-liquid separation is performed by filtration, to obtain a solid deacidized wastewater and liquid pickling wastewater;

[0038]S3, the deacidized wastewater is used to remove hydrogen, fluoride ions, and heavy metal ions, into the biochemical treatment system, remove the nitrate and COD; then discharged.

[0039] Preferably, in step S1, the water content produced by the stainless steel industry is between 13.68 to 61.31 wt%, between 0.37 to 4.29 wt%, between 2.37 ~ 37.59 wt%, CL. - Between 0.02 ~ 5.76 wt%, Fe is between 14.78 ~ 38.64 wt%, no 3 - Between 0.39 ~ 23.55 wt%.

[0040] Preferably, in step S1, the amount of water added and...

Embodiment 2

[0050] A method of recycling residue resource recycling in a stainless steel industry, including the following steps:

[0051] S1, the stainless steel washing waste, that is, the waste acid residue generated by the stainless steel industry, and feed into aerated stirring rinsing apparatus, and water is added;

[0052] S2, after the rinsing ends, solid-liquid separation is performed by filtration, to obtain a solid deacidized wastewater and liquid pickling wastewater;

[0053] S3, the deacidized wastewater is used to remove hydrogen, fluoride ions, and heavy metal ions, into the biochemical treatment system, remove the nitrate and COD; then discharged.

[0054] In the present embodiment, in step S1, the water content of the waste acid residue produced by the stainless steel industry is between 13.68 to 61.31% by weight, and Ni is between 0.37 to 4.29 wt%, and Cr is between 2.37 and 37.59 wt%. , CL - Between 0.02 ~ 5.76 wt%, Fe is between 14.78 ~ 38.64 wt%, no 3 - Between 0.39 ~ 23...

Embodiment 3

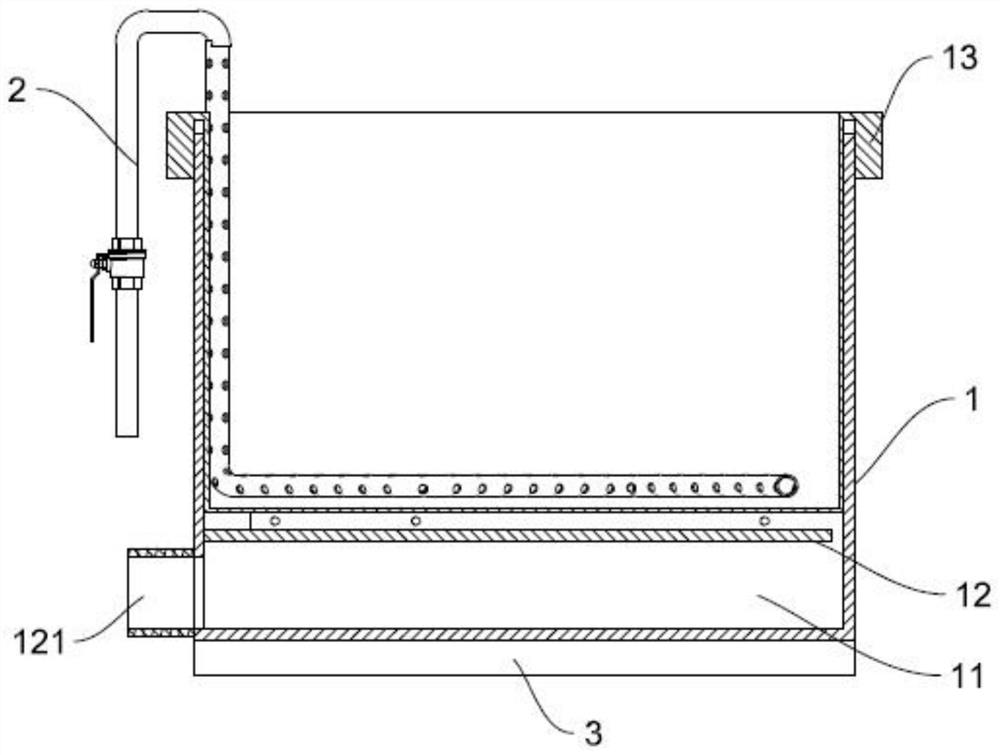

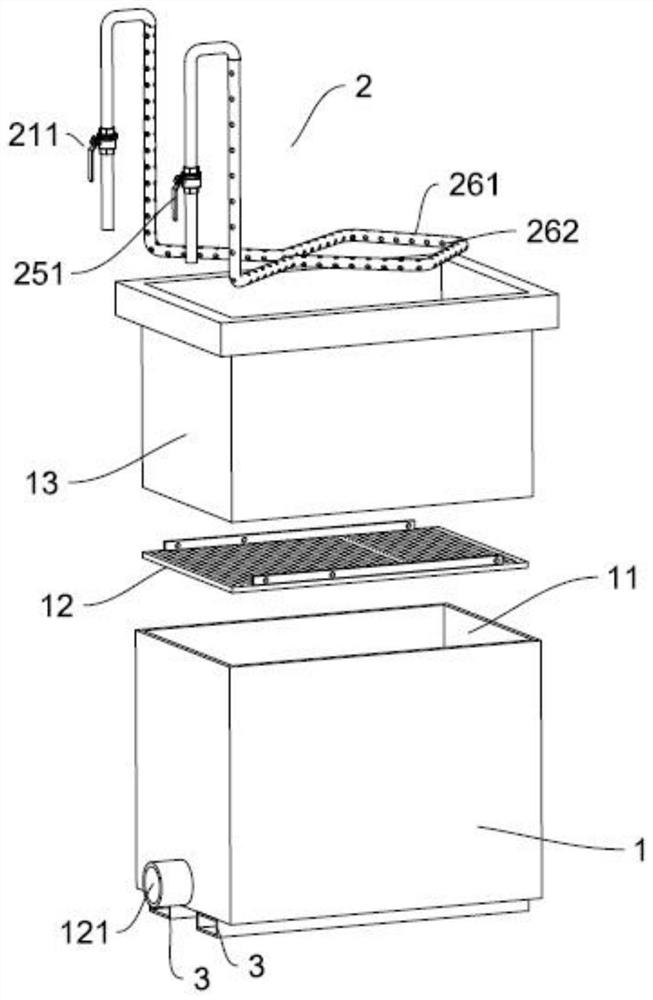

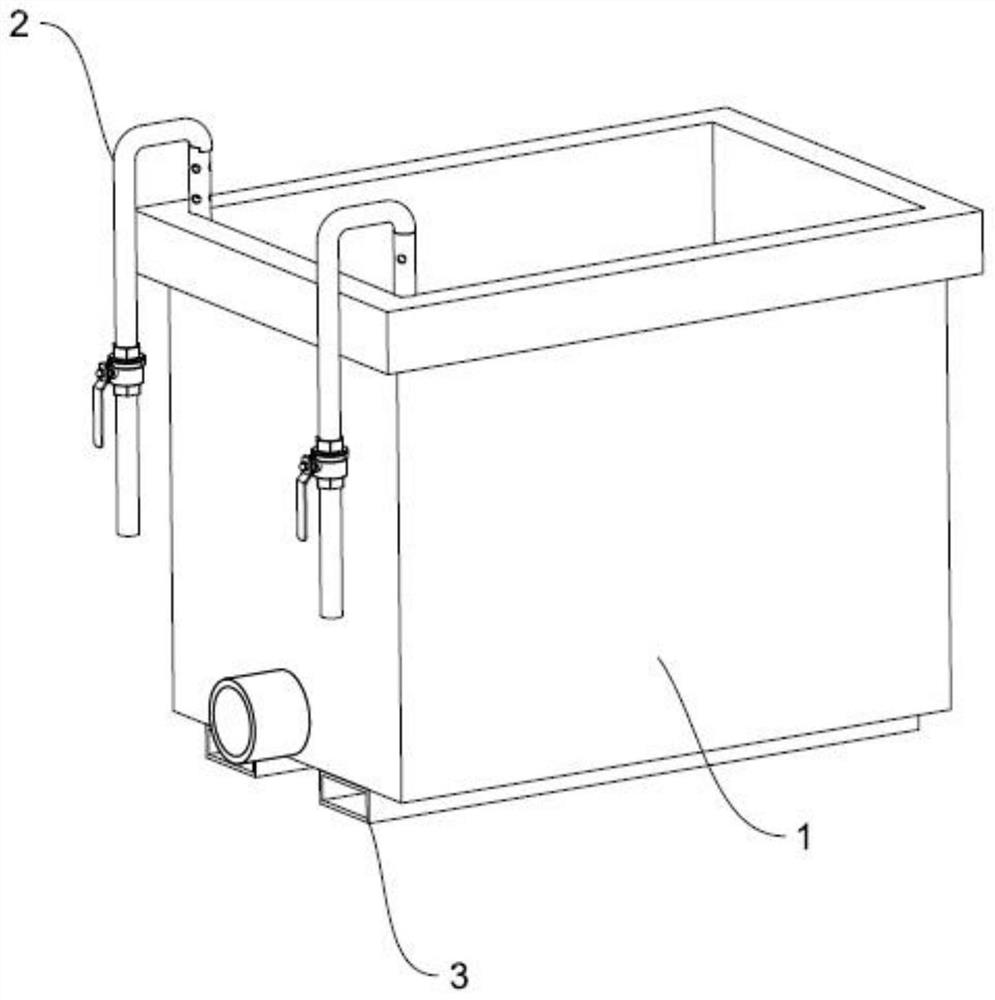

[0062] Based on Example 2, the aeration tube one 22, the aeration tube 23, and the aeration tube three 24 are provided with a vertical via hole 261 and a lateral through hole 262. like Figure 2 As shown, the increasing gas mixing effect is further strengthened by the vertical through hole 261 and the lateral via 262 in the plurality of directions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com