Preparation method of multi-composite-process layered intravascular stent

A technology of vascular stent and composite process, which is applied in the field of vascular stent forming system based on electrospinning and micro-imprinting technology, can solve the problems of difficult stent layered structure, achieve high stent strength, ensure mechanical strength, and be easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] And disclose a kind of preparation method of multi-composite process layered vascular stent, comprising the following steps:

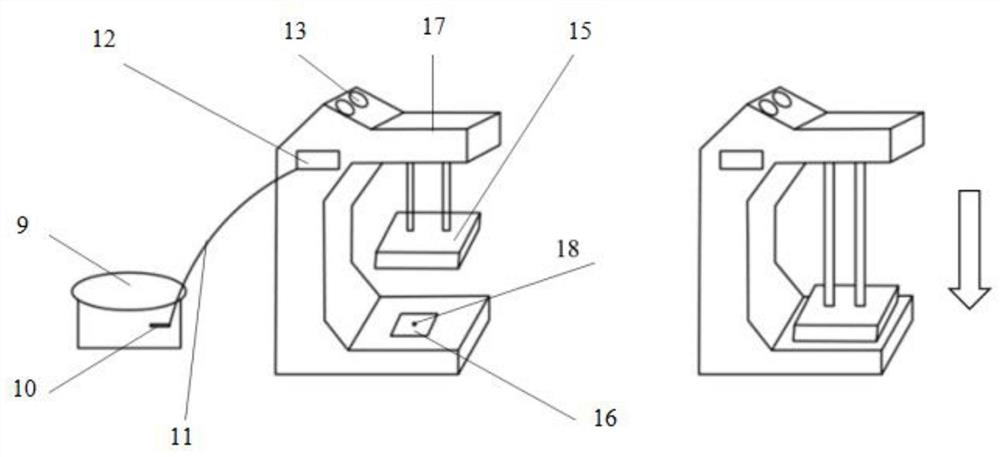

[0045] (1) Forming the basic film of the inner layer of the blood vessel: the solid particles of the raw material are melted into a liquid state and then transferred to the embossing machine platform. Using micro-imprinting technology, the liquid material is embossed into a film by adjusting the air pressure, temperature and time, and then at room temperature Cool to obtain the base film;

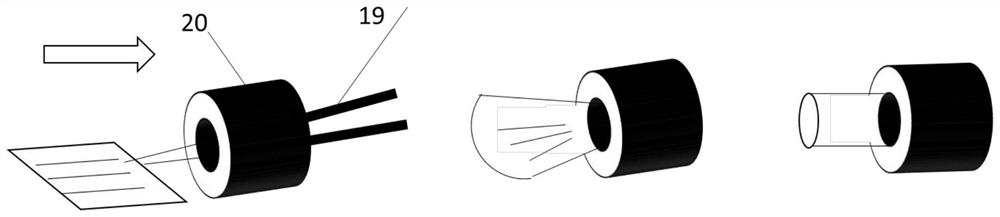

[0046] (2) Form the tubular structure of the vascular stent: use the pre-prepared through-hole cylinder, insert the tweezers from one end of the through-hole cylinder, and extend the other end, clamp the base film and drag it into the through-hole cylinder, The base film is curled into a tubular scaffold under the action of the inner wall of the through-hole cylinder;

[0047] (3) Forming the outer layer of the vascular stent: Driven by the three-axis motion...

Embodiment 1

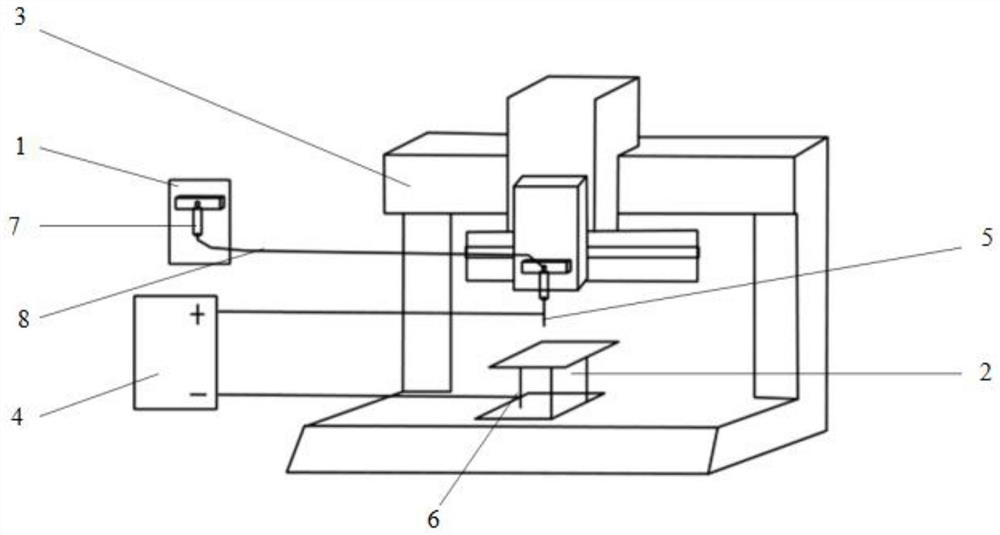

[0050] see figure 1 , a layered vascular stent forming system based on electrospinning and micro-imprinting technology, including a feeding system 1, a spinning collection system 2, a three-axis motion platform 3, and a power supply 4. The feeding system 1 is directly connected to the syringe of the needle Connected; the spinning collection system 2 is fixedly installed on the XY axis platform of the three-axis motion platform 3, the positive pole of the power supply 4 is connected to the metal part of the syringe needle 5, and the negative pole is connected to the metal part of the spinning collector 6.

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, the difference is only in:

[0053] The feeding system 1 includes a micropump syringe 7 and a connecting conduit 8, and the micropump actuator is driven by the micropump controller to push the syringe piston cylinder to extrude the spinning material;

[0054] The spinning collection system 2 is fixedly connected to the XY axis plane of the three-axis motion platform 3, the positive pole of the power supply 4 is connected to the metal part of the syringe needle 5, and the negative pole is connected to the metal part of the spinning collector 6, so that the syringe needle 5 and the spinning collection system 2 to form a high-voltage electric field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com