Preparation method of targeted long-circulation nano-drug carrier for photo-thermal synergistic chemotherapy

A nano-drug carrier and photothermal synergistic technology, applied in nanotechnology, drug combination, pharmaceutical formulation, etc., can solve the problems of short cycle time and inability to fully exert its effect, achieve efficient accumulation, improve biocompatibility, and enrich pores structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a targeted long-circulation nano drug carrier for photothermal synergistic chemotherapy, comprising the following steps:

[0043] (1) preparing mesoporous silica;

[0044] (2) Mesoporous silica coated with polydopamine;

[0045] (3) Loading anticancer drugs: Add the coated mesoporous silica and anticancer drugs obtained in the step (2) into water, and stir for 12 hours to obtain the mesoporous silica loaded with anticancer drugs. silicon;

[0046] (4) Modification of erythrocyte membrane: distearoylphosphatidylethanolamine-polyethylene glycol-biotin and broken erythrocyte membrane were stirred at 4°C for 12 hours, and then extruded continuously through a 200nm filter membrane with a micro extruder. Obtain biotin-modified erythrocyte membrane;

[0047] (5) Add the biotin-modified erythrocyte membrane and the mesoporous silica loaded with anticancer drugs into the PBS solution, and after fully dispersing, filter with a micro extruder to obtain bi...

Embodiment 1

[0063] Concrete operation steps are as follows: (taken material amount " part " is weight part)

[0064] (1) Preparation of mesoporous silica:

[0065] Add 2 parts of n-amyl alcohol and 4 parts of TEOS (tetraethyl orthosilicate) into 30 parts of cyclohexane and stir evenly, add 2.44 parts of CTAB (cetyltrimethylammonium bromide) and 30 parts of deionized water , transferred to a polytetrafluoroethylene reactor after stirring. Place it in an oven at 120°C for 2 hours, wash it with deionized water three times, and dry it in the air at 70°C for one day to obtain a white powder, and then sinter it in a muffle furnace at 550°C for 6 hours to obtain a white powder of mesoporous bismuth Silicon oxide (MSN).

[0066] (2) Mesoporous silica coated with polydopamine:

[0067] After fully mixing and dissolving 5 parts of the prepared alkaline Tris HCl solution and 2 parts of dopamine powder, add 1 part of the prepared mesoporous silica nanoparticles, react under high-speed stirring for...

Embodiment 2

[0079] Using the method of step (1) in Example 1, on the basis of adjusting the time required for dopamine polymerization and the ratio of reactants, mesoporous silica nanoparticles coated with polydopamine were prepared.

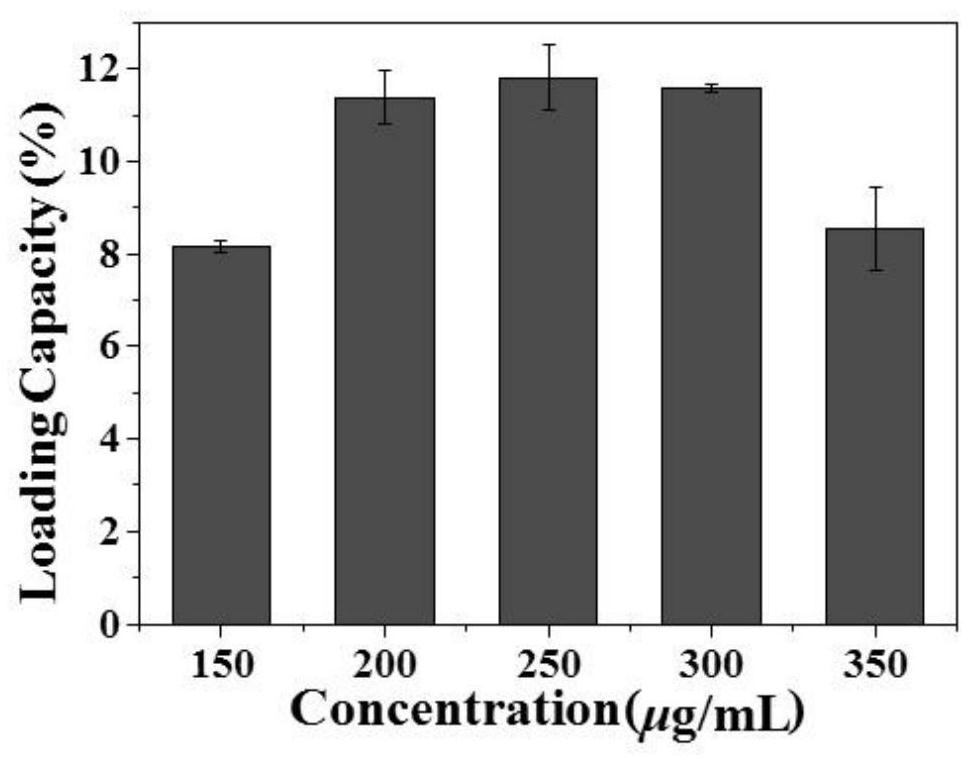

[0080] The drug-loading performance of the prepared mesoporous silica nanoparticles coated with polydopamine was tested, and the results are as follows: figure 1 As shown, the highest drug loading can reach about 11%. Due to the coating, the specific surface area and pore volume of mesoporous silicon with large pore size are reduced. Compared with uncoated mesoporous silicon, the drug loading capacity is reduced, but it still has a higher drug loading capacity. Regulate different concentrations of anticancer drug DOX, and finally get the maximum drug loading. The concentration of DOX is 350 μg / mL, and the drug loading effect is good, which provides the possibility for future loading of drugs or other macromolecules and proteins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com