Biochar doped BiOBrxCl < 1-x > photocatalyst, preparation method and application

A photocatalyst, biochar technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. Limits and other issues to achieve the effect of saving resources, reducing consumption, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: BiOBr 0.2 Cl 0.8 Preparation of photocatalyst:

[0036] (1) Weighing 9.7014g of bismuth nitrate pentahydrate and 2mL of concentrated nitric acid with a mass fraction of 68% were dissolved in 20mL of deionized water, and stirred to obtain a transparent liquid; In deionized water, quickly mix the two solutions with stirring.

[0037] (2) Centrifuge the obtained suspension at 5000r / min, collect the white precipitate, wash it with deionized water three times, dry it in the air at 60°C, and then calcinate it in the air at 300°C for 1h to obtain BiOBr 0.2 Cl 0.8 .

[0038] (3) Take 25mg BiOBr 0.2 Cl 0.8 Add 10mg / L RhB (50mL) solution, react in the dark for 30min to achieve adsorption-desorption equilibrium, then turn on a 350W xenon lamp for visible light catalytic degradation, and add a filter with a cutoff wavelength of 420nm.

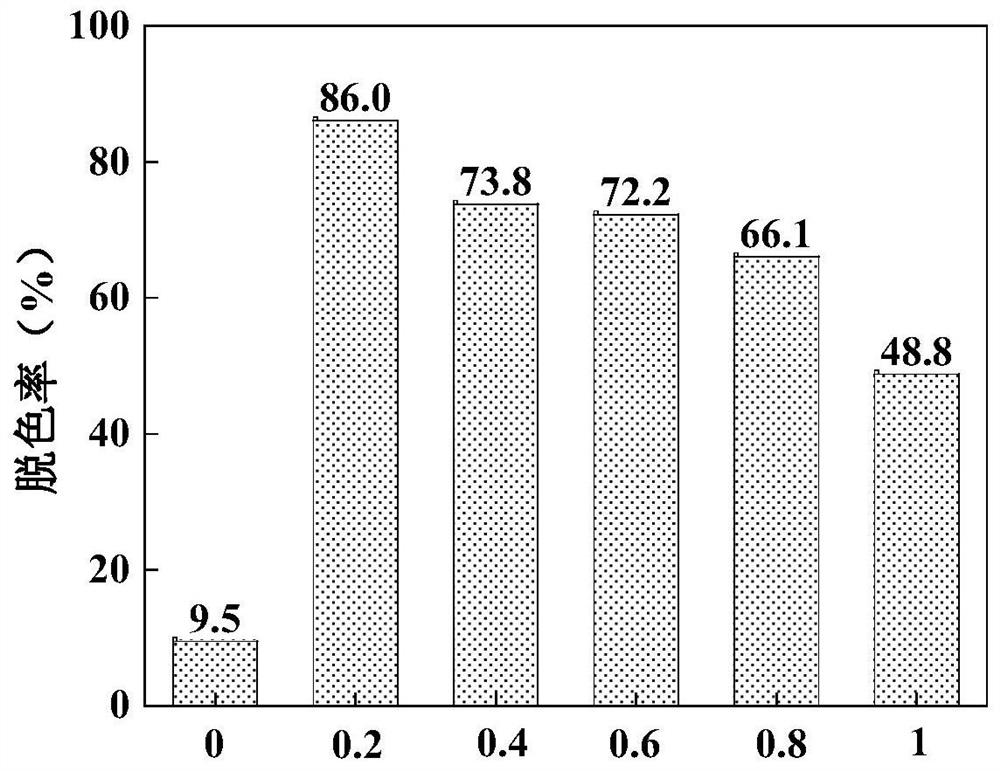

[0039] According to above-mentioned method, adjust the ratio of ammonium bromide and ammonium chloride, prepare following photoca...

Embodiment 2

[0041] Embodiment 2: biochar doping BiOBr 0.2 Cl 0.8 Preparation of photocatalyst

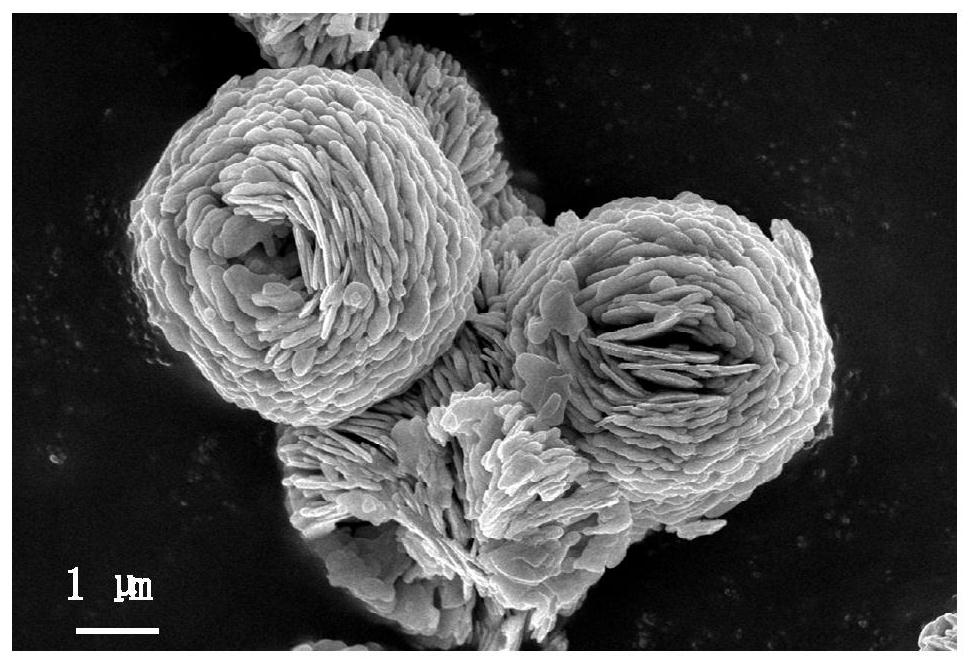

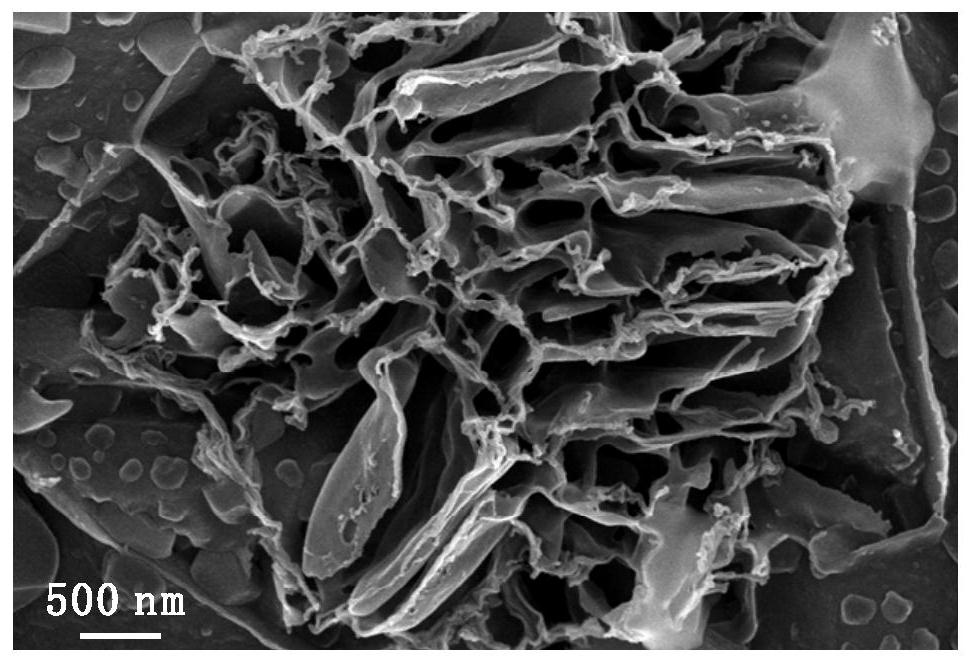

[0042] (1) Wash the dust on the surface of the bamboo leaves with deionized water, dry them in an oven at 60° C., and grind them with a pulverizer to obtain bamboo leaf powder. The bamboo leaf powder that takes by weighing 8.00g is dissolved in the ZnCl of 350mL 1mol / L 2 In the solution, after stirring, use a 0.22 μm filter membrane to filter and wash, put it in a 60°C oven for drying, add 10mL deionized water and 8.00g NaOH for activation treatment, and store in a sealed oven for drying at 60°C. The product was placed in a quartz tube furnace for 2h, 750°C cracking reaction. Wash the cracked powder with water to neutrality and then dry at 60°C to prepare biochar. The structure of the prepared biochar is as follows: image 3 As shown, it can be seen from the transmission electron microscope image of the biochar prepared in this example that the biochar (BC) has a regular floc structure with...

Embodiment 3

[0048] Embodiment 3: biochar doping BiOBr 0.2 Cl 0.8 Preparation of photocatalyst

[0049] (1) Wash the dust on the surface of the bamboo leaves with deionized water, dry them in an oven at 60° C., and grind them with a pulverizer to obtain bamboo leaf powder. The bamboo leaf powder that takes by weighing 8.00g is dissolved in the ZnCl of 400mL 1mol / L 2 solution, stirred and washed with 0.22 μm suction filter, placed in a 60°C oven for drying, then added 10mL deionized water and 8.00g NaOH for activation treatment, sealed and stored in a 60°C oven for drying. The product was placed in a quartz tube furnace for 2.5h, 750°C cracking reaction. The cracked powder was washed with water to neutral and then dried at 60°C to prepare biochar.

[0050] (2) Weighing 9.7014g of bismuth nitrate pentahydrate and 2mL of concentrated nitric acid with a mass fraction of 68% were dissolved in 20mL of deionized water, and stirred to obtain a transparent liquid; In deionized water, quickly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com