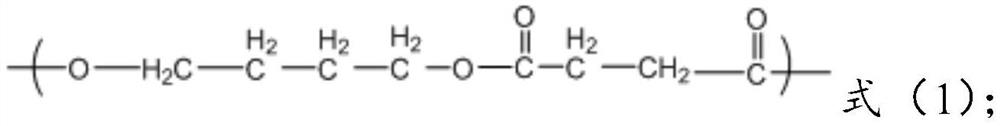

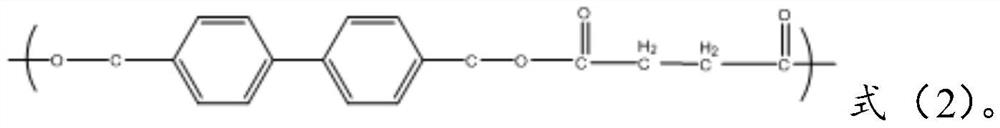

Bio-based copolyester as well as preparation method and application thereof

A copolyester and bio-based technology, which is applied in the field of bio-based copolyester and its preparation, can solve the problems of unfavorable long-term development of the polyester industry, poor UV resistance, and limited application, so as to increase the glass transition temperature and improve Barrier property, effect of reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

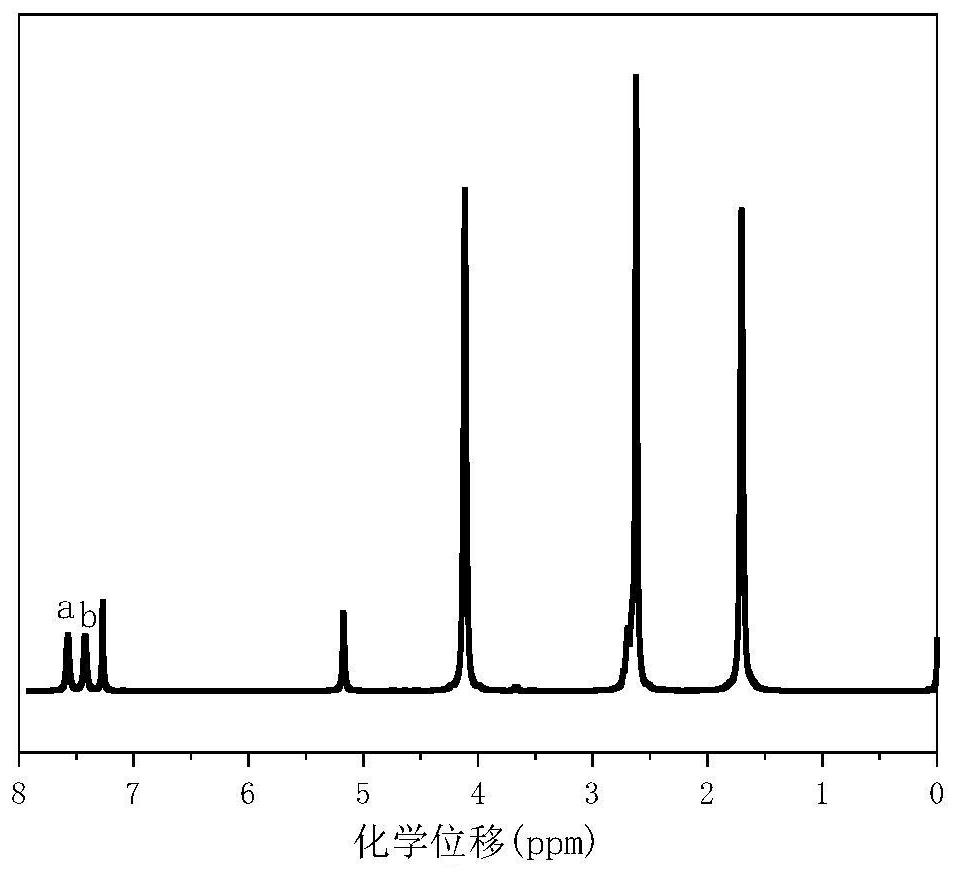

Image

Examples

Embodiment 1

[0031] (1) Under the action of isopropyl titanate, 1,4-dimethyl succinate, 4,4'-biphenyldimethanol and 1,4-butanediol are added to the reaction flask, 4, 4'-biphenyldimethanol and 1,4-butanediol in a molar ratio of 3:1,4,4'-biphenyldimethanol and 1,4-butanediol to dimethyl 1,4-succinate The molar ratio of diol is 0.11:1. The isopropyl titanate accounts for 0.3% of the mass percentage of dimethyl 1,4-succinate, and under the protection of nitrogen, it is stirred and reacted at 190° C. for 4 hours to form a prepolymer.

[0032] (2) Vacuumize the above-mentioned prepolymer to 5Pa, stir and react at 235°C for 5h to obtain copolyester.

[0033] Tensile performance test conditions: test according to ASTM D-638 standard, dumbbell-shaped sample (dimensions of the middle test part: width: 5mm, thickness: 1.6mm), tensile rate: 5mm / min. The tensile properties are shown in Table 1. The glass transition temperature is tested by differential scanning calorimetry (DSC). The test procedure...

Embodiment 2

[0035] (1) Under the action of ethylene glycol antimony, add 1,4-dimethyl succinate, 4,4'-biphenyldimethanol and 1,4-butanediol into the reaction flask, 4,4 '-Biphenyl dimethanol and 1,4-butanediol in a molar ratio of 3:1,4,4'-biphenyl dimethanol and 1,4-butanediol to dimethyl 1,4-succinate The molar ratio of alcohol is 0.2:1. Antimony ethylene glycol accounts for 0.3% by mass of dimethyl 1,4-succinate, and under nitrogen protection, the mixture is stirred and reacted at 190° C. for 4 hours to form a prepolymer.

[0036] (2) Vacuumize the above prepolymer to 5Pa, stir and react at 230°C for 6h to obtain copolyester.

[0037] Performance test conditions: with embodiment 1. The results are shown in Table 1.

Embodiment 3

[0039] (1) Under the action of ethylene glycol antimony, add 1,4-butanedioic acid, 4,4'-biphenyldimethanol and 1,4-butanediol into the reaction flask, 4,4'-biphenyl dimethanol and 1,4-butanediol Benzyldimethanol and 1,4-butanediol, to dimethyl 1,4-succinate in a molar ratio of 3:1,4,4'-biphenyldimethanol and 1,4-butanediol in molar ratio The ratio is 0.26:1. Ethylene glycol antimony accounted for 0.3% of the mass percentage of 1,4-succinic acid, under the protection of nitrogen, stirred and reacted at 190° C. for 4 hours to form a prepolymer.

[0040] (2) Vacuumize the above prepolymer to 5Pa, stir and react at 250°C for 3h to obtain copolyester.

[0041] Performance test conditions: with embodiment 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com