Low-power-consumption flexible thin film transistor based on three layers of insulating media and manufacturing method of low-power-consumption flexible thin film transistor

A flexible film and three-layer insulation technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the limitations of the practical application of flexible organic field effect transistors, large energy consumption, and does not meet the development trend of low energy consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, further describe the present invention in detail through embodiment.

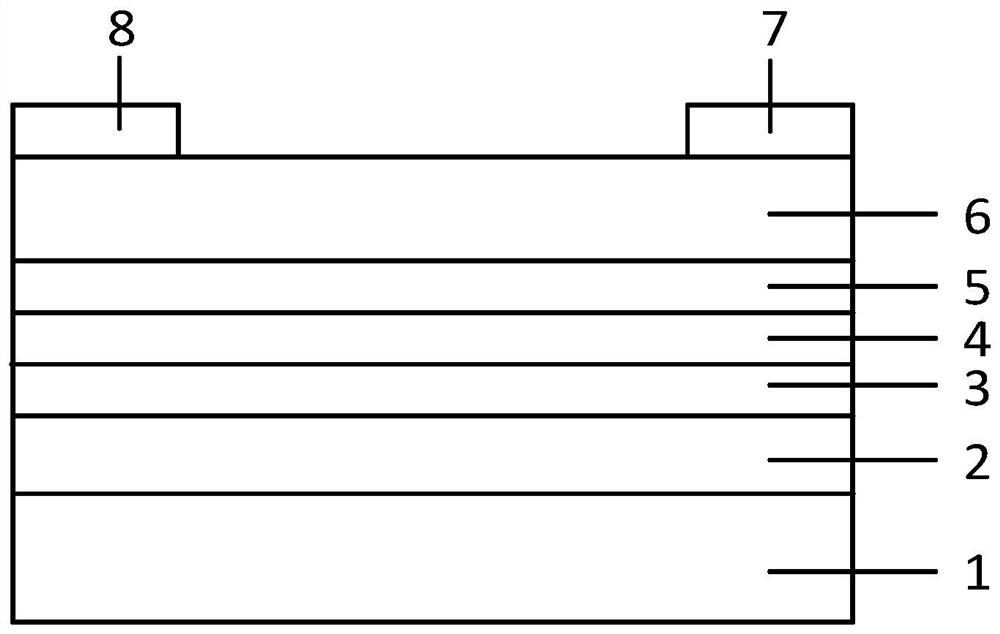

[0047] Such as figure 1 Shown is a specific implementation structure of a low-power flexible thin film transistor based on a three-layer insulating medium, including:

[0048] A flexible substrate 1 made of polyethylene terephthalate (Poly (ethylene Terephthalate), PET); of course, PDMS (polydimethylsiloxane), PI (polyimide) can also be used according to actual needs. ) or PEN (polyethylene naphthalate) and other materials;

[0049] The aluminum (Aluminium, Al) gate electrode 2 located on the upper surface of the PET flexible substrate; of course, it can also be made of metal materials such as gold or silver according to actual needs;

[0050] Aluminum oxide (Aluminum Oxide, Al 2 o 3 ) insulating gate dielectric film 3;

[0051] A polymethyl methacrylate (Poly(MethylMethacrylate), PMMA) insulating dielectric film 4 located on the upper surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com