Sulfonyl conjugated microporous polymer, preparation method and application

A technology of conjugated micropores and sulfonic acid groups, applied in electrochemical generators, electrical components, secondary batteries, etc., can solve problems such as explosions, achieve high chemical stability, high lithium ion conductivity, and good electrochemical The effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of sulfonic acid group conjugated microporous polymer, the steps are as follows:

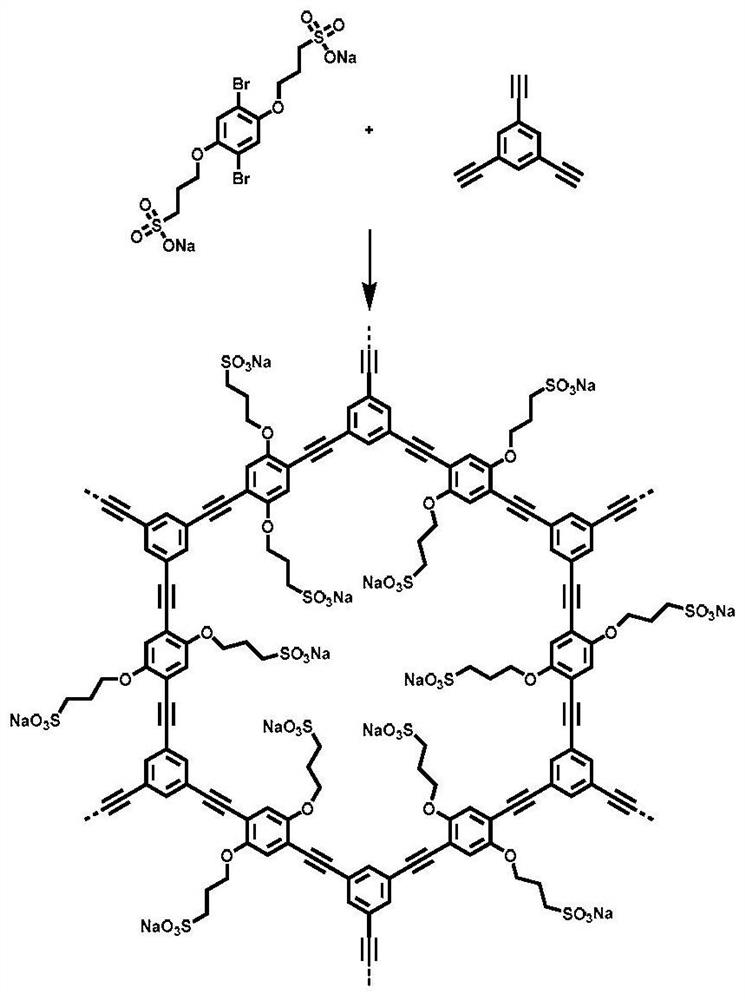

[0052] 1,4-dibromo-2,5-bis(3-sulfopropoxy)benzene (834.2mg, 1.5mmol), tetrakis(triphenylphosphine)palladium (138.5mg, 0.12mmol) and iodide Copper (22.9 mg, 0.12 mmol), and 1,3,5-triethynylbenzene (150.2 mg, 1.0 mmol) were dissolved in 25 mL of toluene and 25 mL of triethylamine under an argon atmosphere. The reaction was heated to 80°C and stirred at 80°C for 36 hours. After cooling to room temperature, the solid was filtered with suction, washed with chloroform, water, methanol and acetone successively, and then Soxhlet extracted with dichloromethane and methanol for 48 hours to remove unreacted monomer or catalyst residue. The sample was dried under vacuum at 80° C. for 24 hours to obtain 563 mg of sulfonic acid-conjugated microporous polymer, with a yield of 76%.

Embodiment 2

[0054] The preparation method of sulfonic acid group conjugated microporous polymer, the steps are as follows:

[0055] 1,4-dibromo-2,5-bis(3-sulfopropoxy)benzene (834.2mg, 1.5mmol), tetrakis(triphenylphosphine)palladium (138.5mg, 0.12mmol) and iodide Copper (22.9 mg, 0.12 mmol), and 1,3,5-tris(4-ethynylphenyl)benzene (378.5 mg, 1.0 mmol) were dissolved in 25 mL of toluene and 25 mL of triethylamine under an argon atmosphere. The reaction was heated to 80°C and stirred at 80°C for 36 hours. After cooling to room temperature, the solid was suction filtered, washed sequentially with chloroform, water, methanol and acetone, and then Soxhlet extracted with dichloromethane and methanol for 48 hours to remove any unreacted monomer or catalyst residue. The sample was dried under vacuum at 80° C. for 24 hours to obtain 815 mg of sulfonic acid group-conjugated microporous polymer, with a yield of 84%.

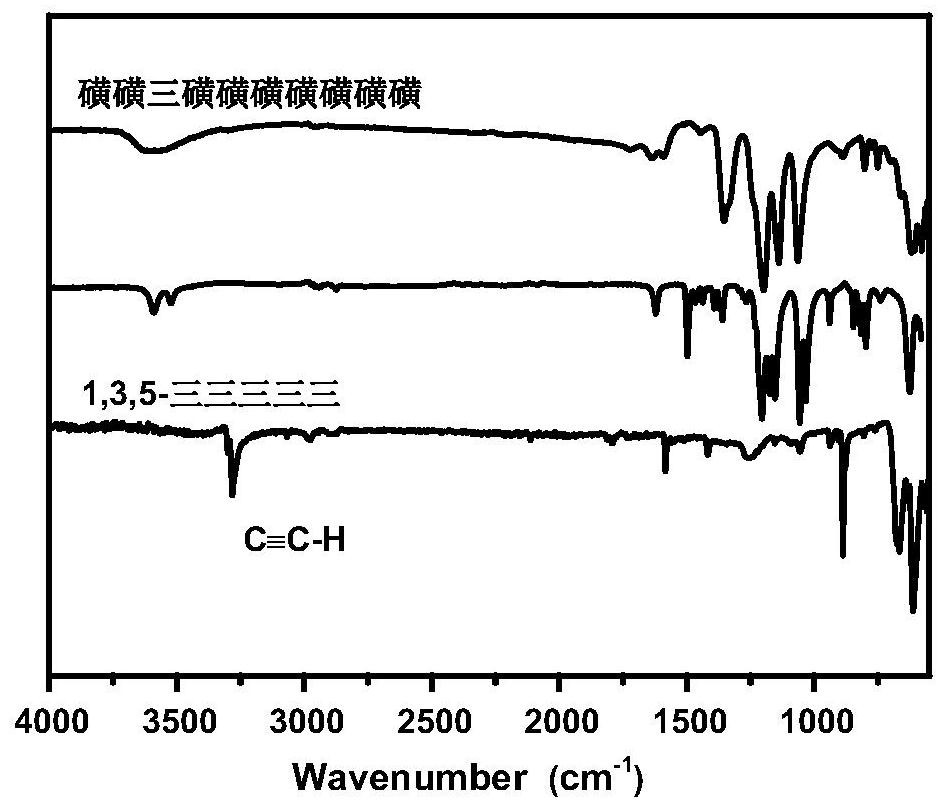

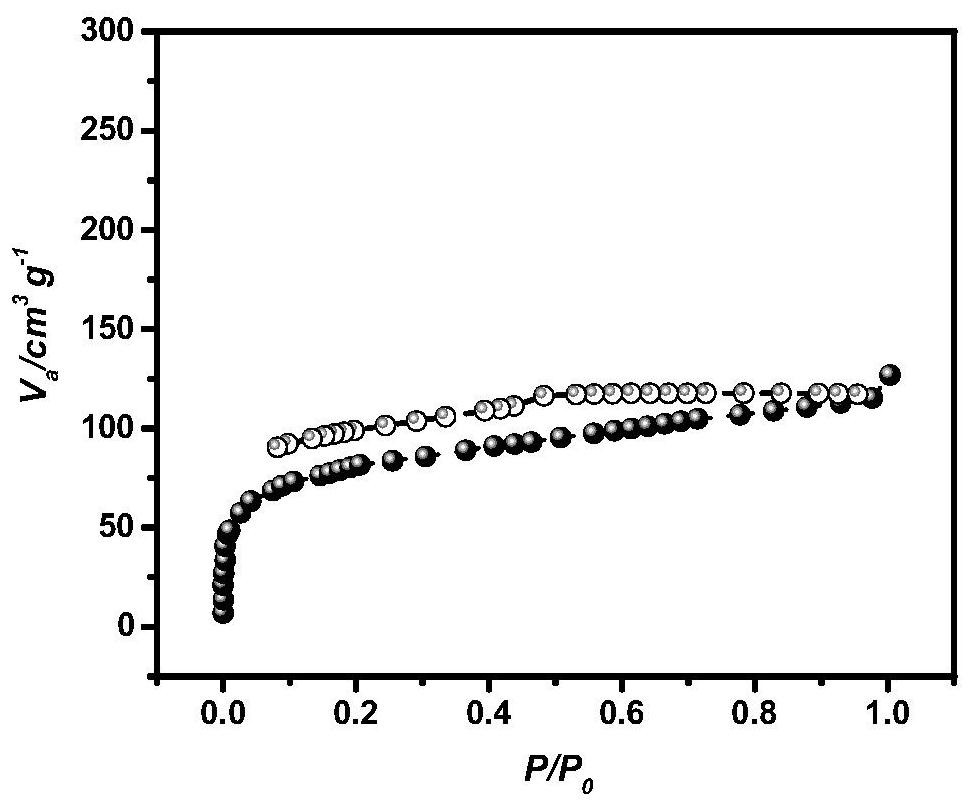

[0056] figure 1 The synthesis route and structural diagram of the sulfonic acid ...

Embodiment 3

[0061] Example 3: Preparation of sulfonic acid conjugated microporous polymer solid electrolyte and AC impedance test

[0062] 1) Preparation of sulfonic acid-conjugated microporous polymer solid electrolyte: Take 100 mg of sulfonic acid-conjugated microporous polymer powder, add it to 20 mL of 1 mol / L lithium bistrifluoromethanesulfonylimide solution, and ultrasonicate for 5 minutes. Stir for a day. The solid was collected by centrifugation at 10000 rpm. Repeat the operation three times until the alkali metal ion exchange is complete, and dry at 80°C overnight; take 6 mg of ion-exchanged sulfonic acid conjugated microporous polymer powder, 3 mg of 1-butyl-3-methylimidazole bis(trifluoromethylsulfonyl ) imide, ground for 10 min, and the mixed powder was kept under pressure at 5 Mpa for 0.5 h, and pressed into a solid electrolyte sheet with a diameter of 5 mm and a thickness of 0.253 mm.

[0063] In the present invention, the alkali metal ion salt is an alkali metal ion salt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com