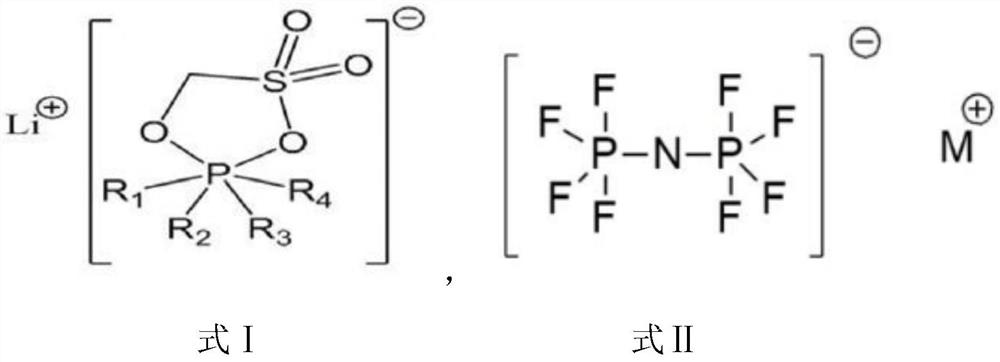

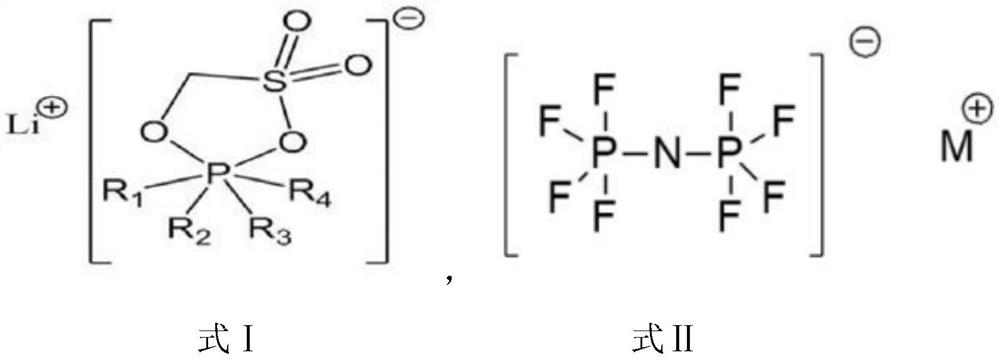

Low-temperature electrolyte and lithium ion battery thereof

An electrolyte and low-temperature technology, which is applied in the field of lithium-ion batteries, can solve the problems of low conductivity of lithium salts, and achieve the effects of improving ion conductivity, reducing internal resistance, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Positive electrode preparation: modifying the positive electrode active material LiCoO 2 , Conductive carbon black and polytetrafluoroethylene are mixed evenly according to the mass ratio of 96.8:2.0:1.2, and then dispersed in N-methyl-2-pyrrolidone to obtain the positive electrode slurry; the positive electrode slurry is evenly coated on both sides of the aluminum foil, After rolling, cutting and tab welding, the positive electrode sheet is obtained, and finally it is baked and vacuum-dried before use.

[0064] Negative electrode preparation: Mix the artificial graphite material, acetylene black and styrene-butadiene rubber evenly according to the mass ratio of 96:2:2, and then disperse them in deionized water to obtain the negative electrode slurry; spread the negative electrode slurry evenly on both sides of the copper foil , after rolling, cutting and tab welding, the negative electrode sheet is obtained, and finally it is baked and vacuum dried before use.

[0065...

Embodiment 2

[0071] Different from Example 1 is the preparation of electrolyte:

[0072] 1) In a nitrogen-filled glove box (O 2 2 (0<3ppm), prepare an organic solvent, the organic solvent is composed of the following components in mass percentage: 0.5% vinylene carbonate, 1% ethyl methyl carbonate, and the balance is ethylene carbonate with a mass ratio of 1:1:1 , a mixture of diethyl carbonate and propylene carbonate;

[0073] 2) Slowly add sulfur-containing oxygen-containing fluoroalkyl phosphate lithium into the organic solvent to form a lithium salt solution with a concentration of 1.2mol / L;

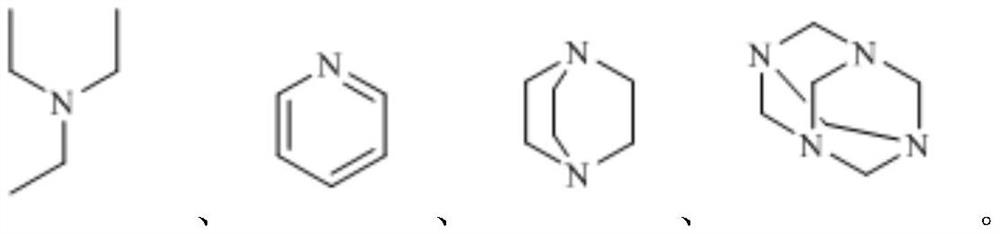

[0074] 3) Add 2% 1,3-propane sultone, 1.5% hexanetrinitrile, 1.5% lithium bistetrafluorophosphorimide and 1% triethylene to the lithium salt solution Diamine (c), after mixing evenly, is the electrolyte.

[0075] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0077] Different from Example 1 is the preparation of electrolyte:

[0078] 1) In a nitrogen-filled glove box (O 2 2 (0<3ppm), prepare an organic solvent, the organic solvent is composed of the following components in mass percentage: 0.5% vinylene carbonate, 1% ethyl methyl carbonate, and the balance is ethylene carbonate with a mass ratio of 1:1:1 , a mixture of diethyl carbonate and propylene carbonate;

[0079] 2) Slowly add sulfur-containing oxygen-containing fluoroalkyl phosphate lithium into the organic solvent to form a lithium salt solution with a concentration of 1.2mol / L;

[0080] 3) Add 2% 1,3-propane sultone, 1.5% hexanetrinitrile, 1.7% lithium bistetrafluorophosphorimide and 0.8% triethylene to the lithium salt solution Diamine (c), after mixing evenly, is the electrolyte.

[0081] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com