Composite support material for reverse osmosis membrane and preparation method of composite support material

A technology of composite support and reverse osmosis membrane, which is applied in the fields of semipermeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc. It can solve the problem of reverse osmosis that affects the mechanical strength of the support material, the pore structure distribution, and the restriction of the support material. Membrane, poor bonding effect and other problems, to achieve the effect of large flux, long service life, and reduce the average pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

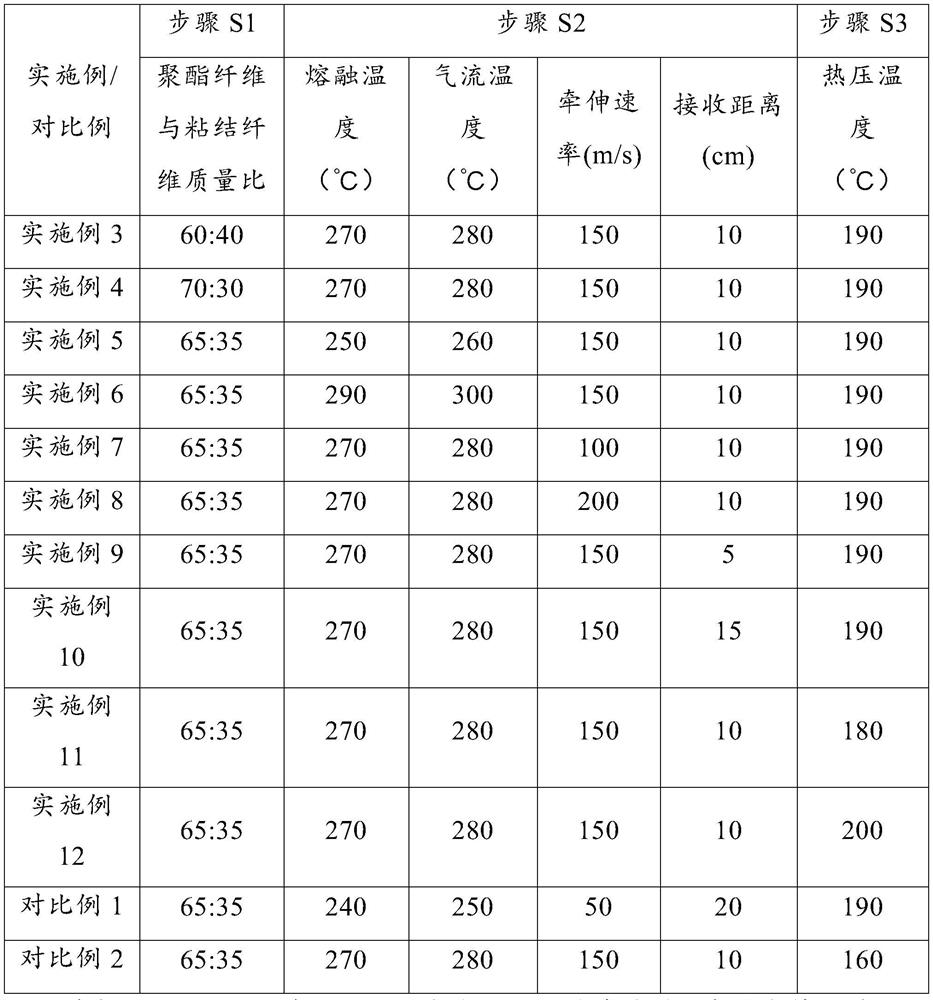

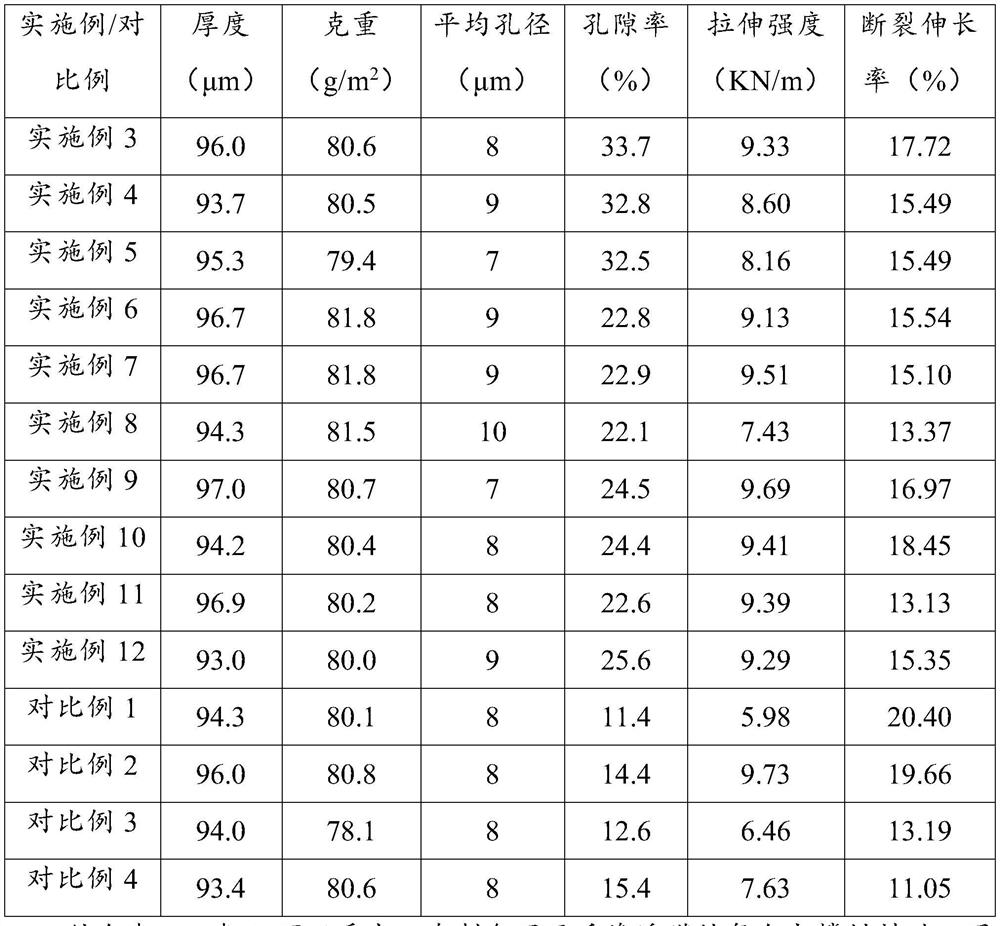

Examples

preparation example Construction

[0032] The invention provides a method for preparing a composite support material for a reverse osmosis membrane, comprising the steps of:

[0033] S1, adopt papermaking method to prepare polyester non-woven fabric;

[0034] S2, performing melt-blown spinning on the ethylene-methyl acrylate copolymer or the modified ethylene-methyl acrylate copolymer to obtain a melt-blown non-woven fabric;

[0035] S3. Superimpose the melt-blown nonwoven fabric obtained in step S2 on the upper surface of the polyester nonwoven fabric obtained in step S1, and heat and press to obtain a composite support material for a reverse osmosis membrane.

[0036] In step S1, the preparation of polyester non-woven fabric by the papermaking method specifically includes the following steps:

[0037]Mix a predetermined amount of polyester fiber and binder fiber with water and perform beating treatment to obtain a fiber slurry; fully dilute the fiber slurry into a fiber suspension and then sheet it into a ne...

Embodiment 1

[0053] This embodiment provides a method for preparing a composite support material for a reverse osmosis membrane, comprising the following steps:

[0054] S1. Preparation of polyester non-woven fabric by papermaking method

[0055] Mix the polyester fiber and the binder fiber according to the mass ratio of 65:35 and place them in a beater, then add water for beating treatment to obtain a fiber slurry; then add water to the fiber slurry and stir evenly to make it fully diluted After the fiber suspension is formed, it is sheeted into a net, and then dried at 80°C to obtain a polyester non-woven fabric. Wherein, the process bonding temperature of the bonding fiber is 180-200°C.

[0056] S2, preparation of melt-blown non-woven fabric

[0057] Select an ethylene-methyl acrylate copolymer with a melting point of 220°C, add it to a screw extruder, heat and melt it at 270°C, and then spray it out from the spinneret hole on the melt-blown die, and pass through a hot air flow of 280...

Embodiment 2

[0062] This example provides a method for preparing a composite support material for a reverse osmosis membrane. Compared with Example 1, the difference is that the ethylene-methyl acrylate copolymer is modified, and the modified ethylene-methyl acrylate Methyl acrylate copolymer was used as a raw material for melt blown spinning, and the rest of the steps were consistent with Example 1, and will not be repeated here.

[0063] Wherein, the preparation of modified ethylene-methyl acrylate copolymer comprises the steps:

[0064] S21, preparation of nickel complex catalyst

[0065] Dissolve aniline in dichloromethane, then add trimethyl phosphite and elemental iodine, control the molar ratio of aniline, trimethyl phosphite and iodine to 5:2:1, fully stir the reaction for 10h, then add hydrochloric acid (12mol / L), adding sodium bicarbonate solution and sodium chloride solution successively for extraction to obtain an extraction product; spin-drying the extraction product and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com