Antibacterial and antiviral formaldehyde removal coating and preparation method thereof

An anti-virus and coating technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as poor flame retardancy, human health hazards, and low aldehyde removal rate of aldehyde-removing coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

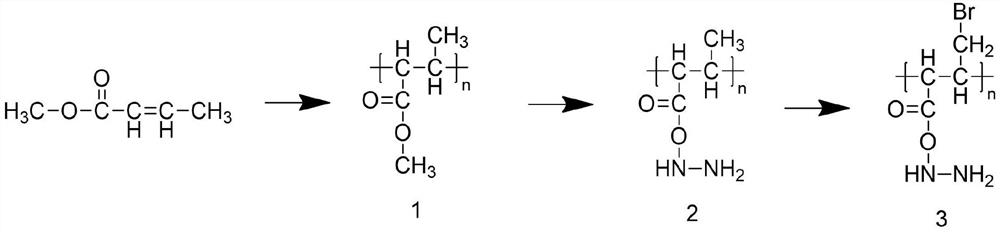

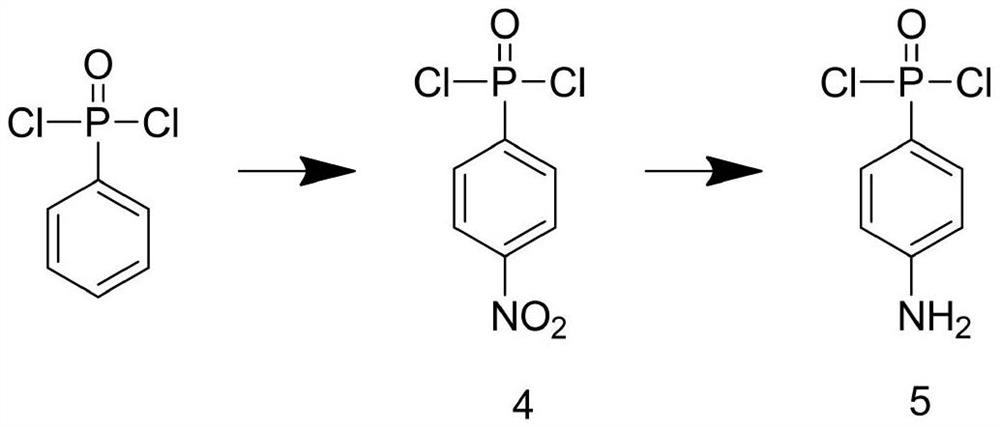

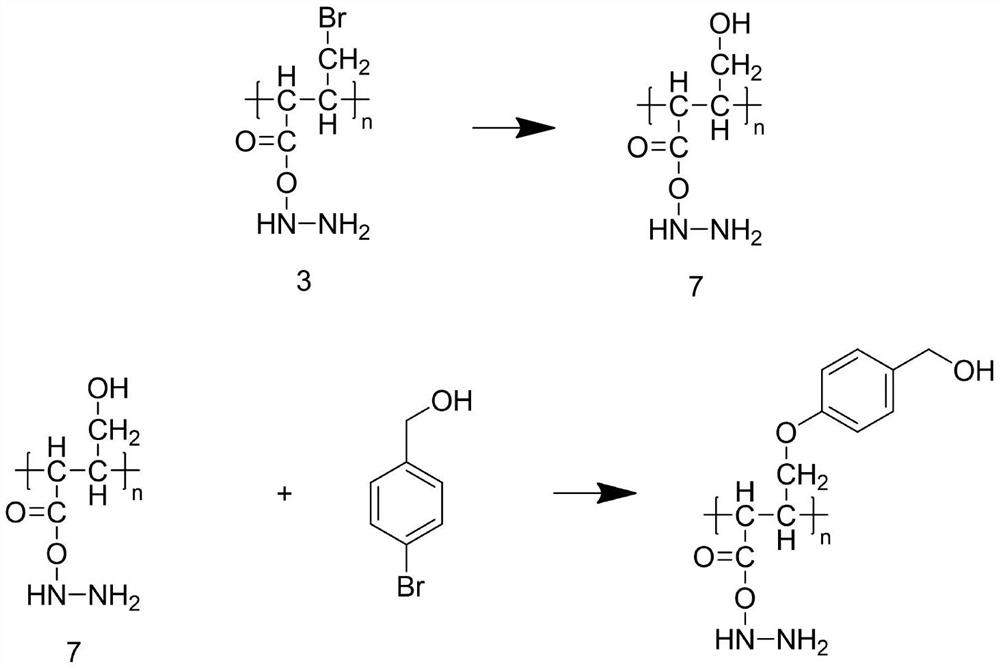

Method used

Image

Examples

Embodiment 1

[0035] An antibacterial and antiviral aldehyde-removing coating, comprising the following raw materials in parts by weight: 140 parts of nano-inorganic aldehyde-removing resin, 110 parts of water, 0.5 part of defoamer 6154, 0.5 part of odor-cleaning bactericide 11G, 3 parts of sodium salt dispersant, 1 1 part of polyoxyethylene alkylphenol ether, 1 part of cellulose 250, 1 part of net taste multifunctional 168, 20 parts of negative ion powder, 40 parts of barium sulfate, 140 parts of titanium dioxide, 120 parts of heavy calcium powder, 20 parts of talcum powder, 70 parts Parts of silica fume powder, 40 parts of nano-carbon dioxide, 5 parts of propylene glycol, 180 parts of deodorant emulsion 380, 3 parts of deodorant film-forming aid, 1 part of defoamer 4210, 6 parts of AEM-5700T antifungal agent, 0.5 part of thickener Agent 621, 1 part of thickener 935, 0.5 part of thickener 80;

[0036] The antibacterial and antiviral aldehyde-removing coating is prepared by the following st...

Embodiment 2

[0043] An antibacterial and antiviral aldehyde-removing coating, comprising the following raw materials in parts by weight: 150 parts of nano-organic aldehyde-removing resin, 120 parts of water, 1 part of defoamer 6154, 1 part of odor-cleaning bactericide 11G, 4 parts of sodium salt dispersant, 2 parts of Parts of polyoxyethylene alkylphenol ether, 2 parts of cellulose 250, 2 parts of net taste multifunctional 168, 25 parts of negative ion powder, 50 parts of barium sulfate, 150 parts of titanium dioxide, 125 parts of heavy calcium powder, 25 parts of talcum powder, 75 parts Parts of silica fume powder, 50 parts of nano-carbon dioxide, 10 parts of propylene glycol, 200 parts of net odor emulsion 380, 4 parts of net odor film-forming aid, 1.5 parts of defoamer 4210, 7 parts of AEM-5700T antifungal agent, 1 part of thickener Agent 621, 2 parts of thickener 935, 1 part of thickener 80;

[0044] The antibacterial and antiviral aldehyde-removing coating is prepared by the following...

Embodiment 3

[0051] An antibacterial and antiviral aldehyde-removing coating, comprising the following raw materials in parts by weight: 160 parts of nano-inorganic aldehyde-removing resin, 130 parts of water, 1.5 parts of defoamer 6154, 1.5 parts of odor-cleaning bactericide 11G, 5 parts of sodium salt dispersant, 3 parts of Parts of polyoxyethylene alkylphenol ether, 3 parts of cellulose 250, 3 parts of net taste multifunctional 168, 30 parts of negative ion powder, 60 parts of barium sulfate, 160 parts of titanium dioxide, 130 parts of heavy calcium powder, 30 parts of talcum powder, 80 parts Parts of silica fume powder, 60 parts of nano-carbon dioxide, 15 parts of propylene glycol, 220 parts of deodorant emulsion 380, 5 parts of deodorant film-forming aid, 2 parts of defoamer 4210, 8 parts of AEM-5700T antifungal agent, 1.5 parts of thickener Agent 621, 3 parts of thickener 935, 1.5 parts of thickener 80;

[0052] The antibacterial and antiviral aldehyde-removing coating is prepared by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com