Carbon nitride antibacterial material, and preparation method and application thereof

An antibacterial material, carbon nitride technology, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve problems such as high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the synthetic method of carbon nitride antibacterial material comprises following specific steps:

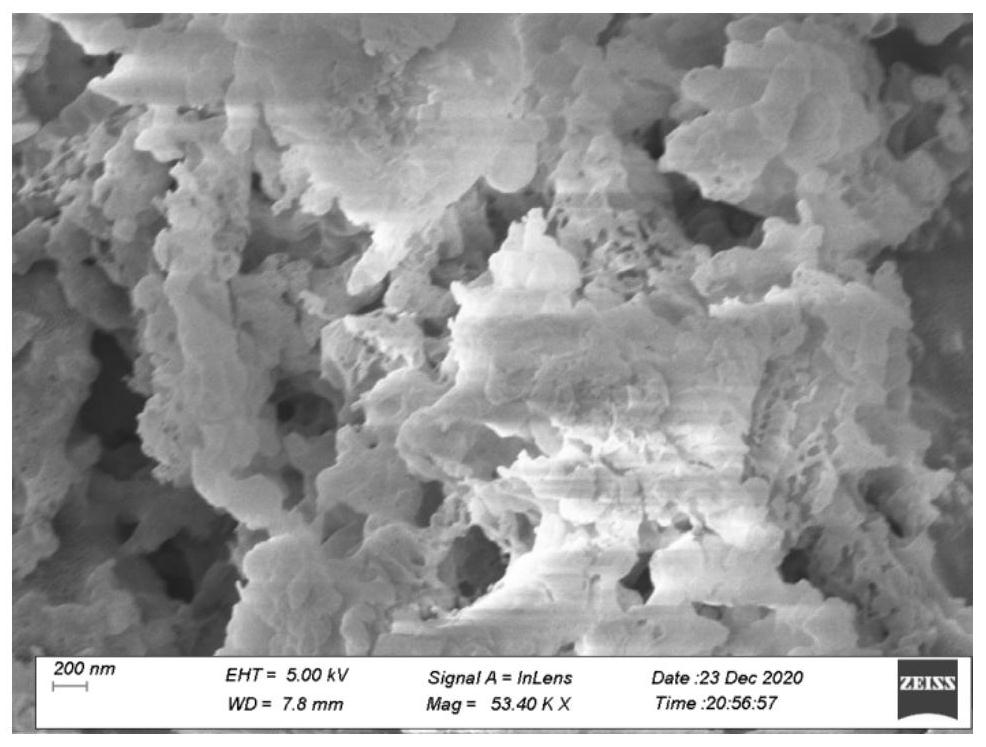

[0030] Mix 10 grams of melamine, 10 grams of cyanuric acid, and 2 grams of a dopant molecule, 2,6-diaminopurine: Melamine is first dissolved in deionized water (500 mL), followed by cyanuric acid and 2,6-diaminopurine were dissolved in water respectively, and then the 2,6-diaminopurine aqueous solution was added dropwise into the melamine aqueous solution and fully stirred, and then the cyanuric acid aqueous solution was slowly added dropwise to 2, In the mixed solution of 6-diaminopurine and melamine, stir evenly, after standing still, use 200nm filter membrane to suction filter, obtain white cake-like precipitate, wash clean with deionized water, obtain melamine, cyanuric acid and dopant molecular self- Assembled precursors. Dry the precursor at 50°C, grind it evenly with a mortar, put it into a corundum boat, and then put it into a vacuum tube furnace pr...

Embodiment 2

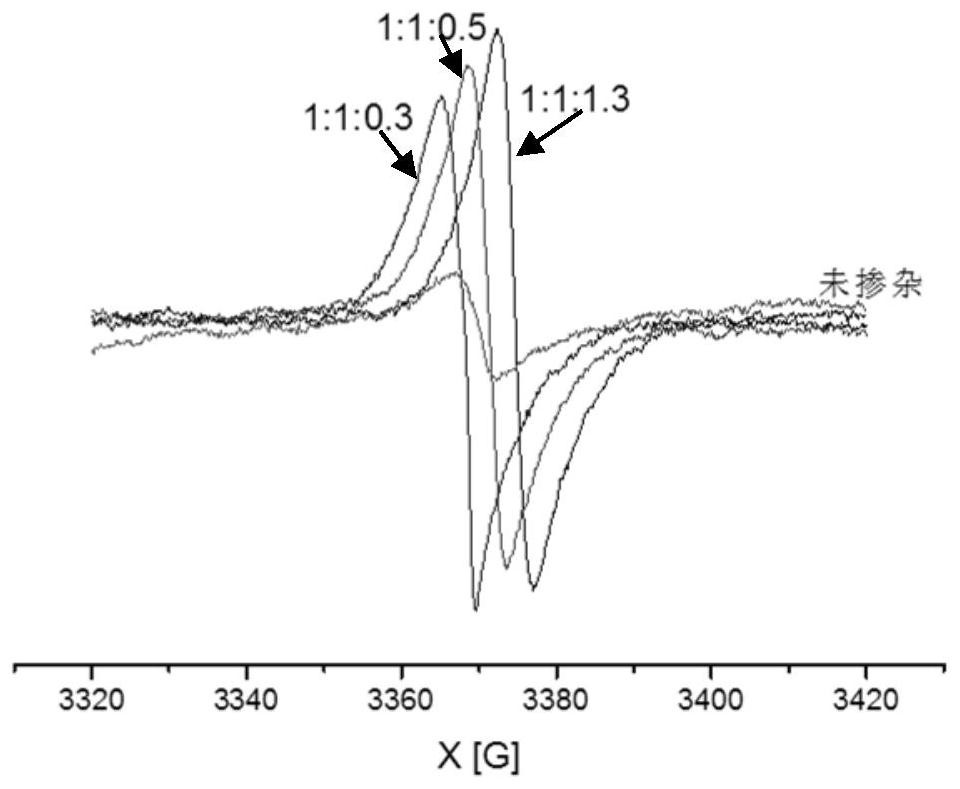

[0032] Embodiment 2: According to the method of embodiment 1, melamine, cyanuric acid and doped heterocyclic molecule 2,6-diaminopurine are respectively 1:1:0, 1:1:0.3, 1 according to the mass ratio :1:0.5, 1:1:1.3 to prepare carbon nitride material, the electron paramagnetic resonance spectrum is as follows image 3 shown by image 3 It can be seen that with the gradual increase of the heterocyclic doping concentration, the gradual enhancement of the electron paramagnetic resonance spectrum signal indicates that the asymmetric lone pair electron number density in the carbon nitride material gradually increases, and the lone pair of the purine heterocycle Electrons have been efficiently embedded in the carbon nitride material.

Embodiment 3

[0033] Embodiment 3: According to the method of embodiment 1, melamine, cyanuric acid and doped heterocyclic molecule 2,6-diaminopurine are respectively 1:1:1.3, 1:1:1.7, 1 according to the mass ratio :1:2.5 Prepare carbon nitride material, the result is as follows Figure 4 as shown, Figure 4 The middle and infrared spectra are 2,6-diaminopurine from bottom to top and the ratio of melamine, cyanuric acid and doped heterocyclic molecule 2,6-diaminopurine is 1:1:0 when synthesized, respectively, 1:1:1.3, 1:1:1.7, 1:1:2.5 carbon nitride materials, from Figure 4 It can be seen that a small peak at 820 cm gradually becomes smaller as the heterocyclic doping concentration gradually increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com