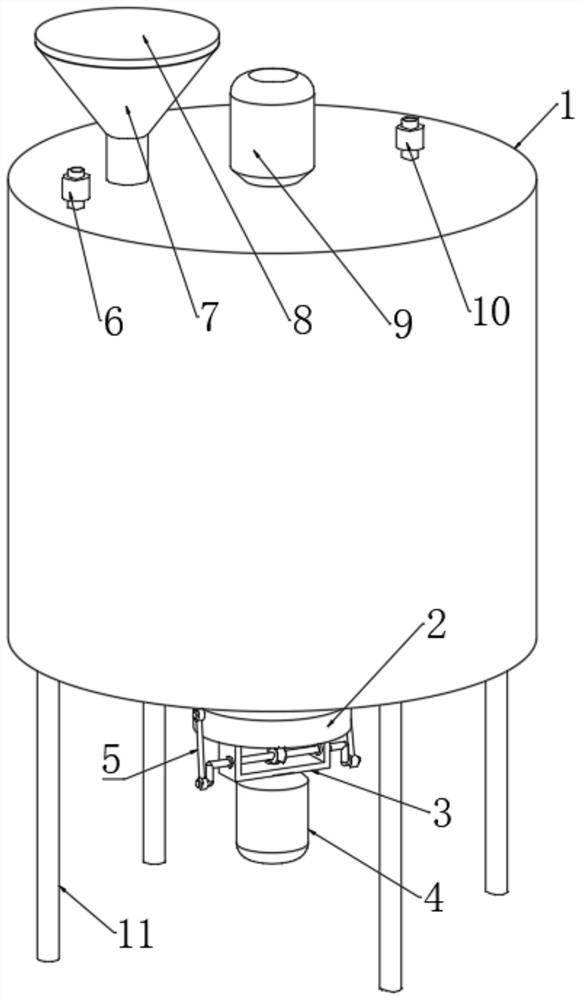

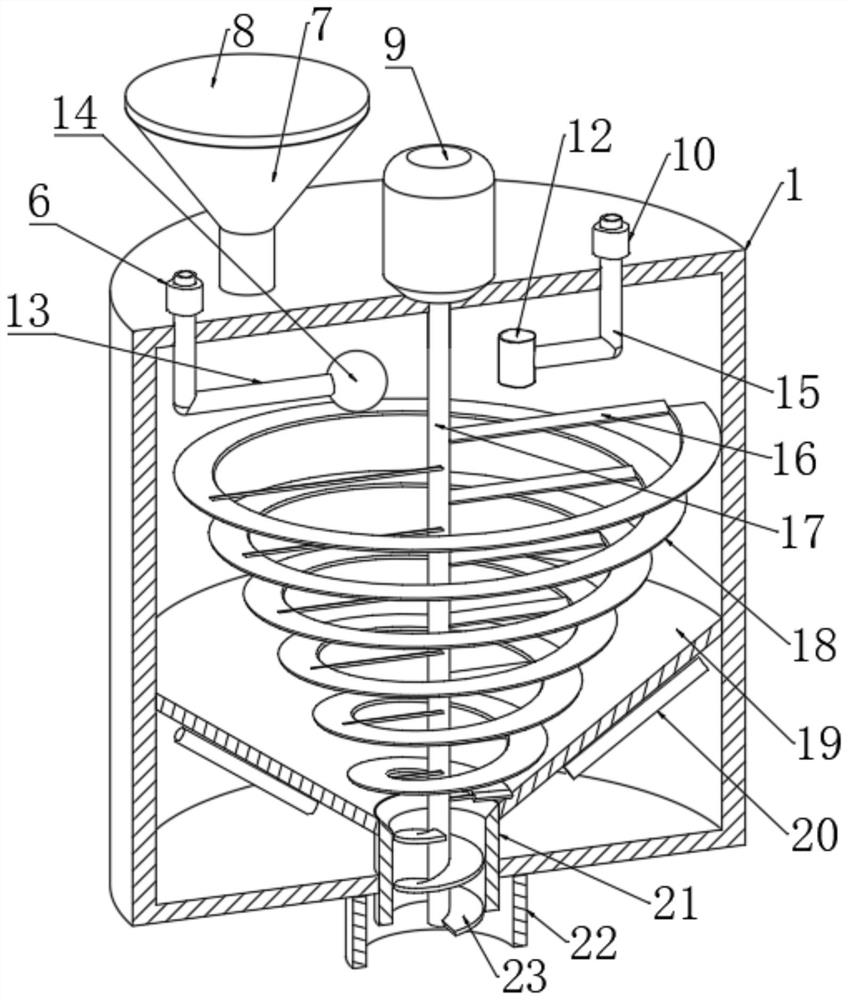

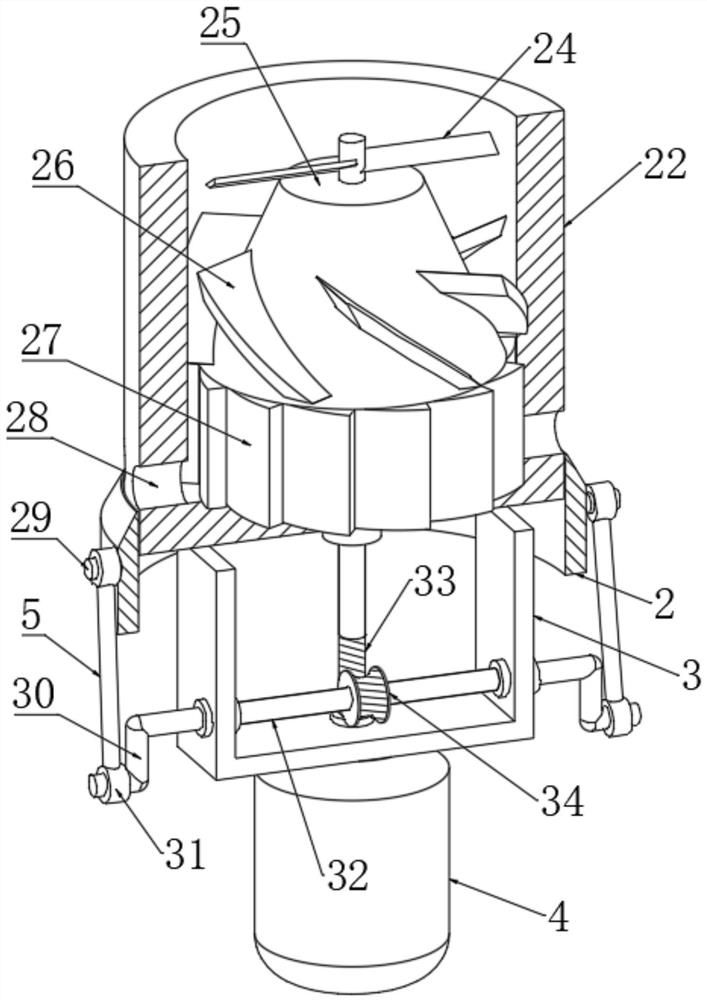

Biological fermentation bran and processing equipment thereof

A technology for biological fermentation and processing equipment, applied in the directions of biochemical equipment and methods, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. Unable to be eaten by livestock and poultry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of biologically fermented bran, said biologically fermented bran is made by the following steps, comprising;

[0035] S1, removing impurities from the bran raw material, after the removal of impurities, use a plant pulverizer to crush the bran raw material, pass through a 40-mesh sieve, and pack it into bags for subsequent use;

[0036] S2. Take the sieved bran and standard flour in S1, mix them into bran powder, add water and mix well, and keep the humidity at 55%-60%. When adding water to the bran powder in S2, 10g / L, peptone 1g / L and nutrient salt solution, nutrient salt solution consists of ammonium sulfate 14g / L, potassium dihydrogen phosphate 20g / L, urea 3.0g / L, magnesium sulfate heptahydrate 3.0g / L, calcium chloride 3.0g / L L, cobalt chloride hexahydrate 3.7g / L, zinc sulfate heptahydrate 1.4g / L, magnesium sulfate monohydrate 1.6g / L and iron sulfate heptahydrate 5.0g / L;

[0037] S3, adding the selected dry yeast into the bran powder of wet water in S2 in a...

Embodiment 2

[0043] Embodiment 2: the difference based on Embodiment 1 is;

[0044] S1, removing impurities from the bran raw material, after the removal of impurities, use a plant pulverizer to crush the bran raw material, pass through a 40-mesh sieve, and pack it into bags for subsequent use;

[0045] S2. Take the sieved bran and standard flour in S1, mix them into bran powder, add water and mix well, and keep the humidity at 55%-60%. When adding water to the bran powder in S2, 10g / L, peptone 1g / L and nutrient salt solution, nutrient salt solution consists of ammonium sulfate 14g / L, potassium dihydrogen phosphate 20g / L, urea 3.0g / L, magnesium sulfate heptahydrate 3.0g / L, calcium chloride 3.0g / L L, cobalt chloride hexahydrate 3.7g / L, zinc sulfate heptahydrate 1.4g / L, magnesium sulfate monohydrate 1.6g / L and iron sulfate heptahydrate 5.0g / L;

[0046] S3, adding the selected dry yeast into the bran powder of wet water in S2 in a proportion of 0.4% and mixing well, and then placing it in a...

Embodiment 3

[0051] Embodiment 3: the difference based on embodiment 1 is;

[0052] S1, removing impurities from the bran raw material, after the removal of impurities, use a plant pulverizer to crush the bran raw material, pass through a 40-mesh sieve, and pack it into bags for subsequent use;

[0053] S2. Take the sieved bran and standard flour in S1, mix them into bran powder, add water and mix well, and keep the humidity at 55%-60%. When adding water to the bran powder in S2, 10g / L, peptone 1g / L and nutrient salt solution, nutrient salt solution consists of ammonium sulfate 14g / L, potassium dihydrogen phosphate 20g / L, urea 3.0g / L, magnesium sulfate heptahydrate 3.0g / L, calcium chloride 3.0g / L L, cobalt chloride hexahydrate 3.7g / L, zinc sulfate heptahydrate 1.4g / L, magnesium sulfate monohydrate 1.6g / L and iron sulfate heptahydrate 5.0g / L;

[0054] S3, adding the selected dry yeast into the bran powder of wet water in S2 in a proportion of 0.4% and mixing well, and then placing it in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com