Nitrogen-doped hollow amorphous carbon shell material, preparation method and application

A nitrogen-doped, amorphous carbon technology, applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems of dendrites piercing the diaphragm and increasing the polarization of battery voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

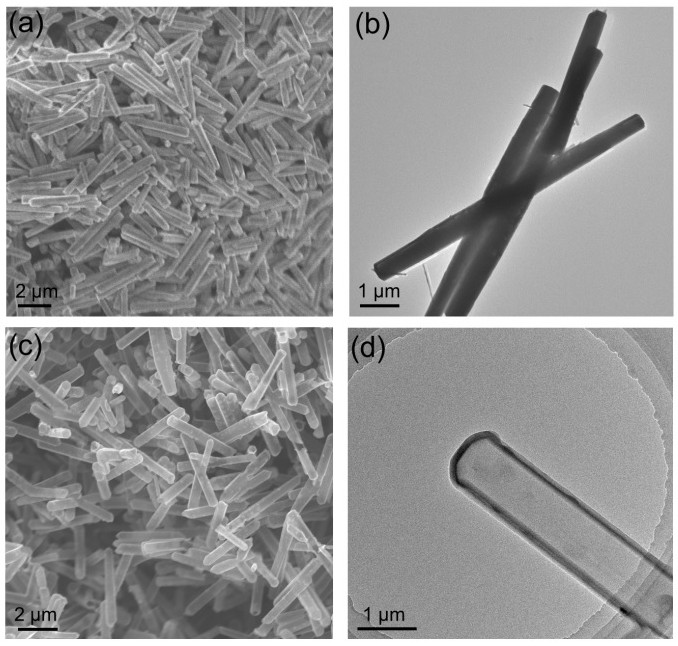

[0031] Preparation of a nitrogen-doped hollow amorphous carbon shell sodium metal battery anode material:

[0032] (1) Zinc oxide nanorods

[0033] ZnO nanorods were synthesized by a water bath method.

[0034] The preparation steps are as follows: Zinc acetate dihydrate (C 4 h 6 o 4 ·Zn·2H 2 O, 1.1 g), hexamethylenetetramine (C 6 h 12 N 4 , 0.7 g) was dissolved in 200 ml of deionized water, heated in a water bath at 90 °C for 5 hours, and centrifuged to dry to obtain white zinc oxide powder.

[0035] (2) Preparation of nitrogen-doped hollow amorphous carbon shells

[0036] Dissolve 240 mg of dopamine hydrochloride in 74 ml of alcohol and 34 ml of deionized water, dissolve 180 mg of Tris in 8 ml of alcohol and 4 ml of deionized water, and then slowly add the Tris buffer into the dopamine hydrochloride solution dropwise.

[0037] Pour the zinc oxide powder in (1) into the above solution, and stir for 12 hours in the dark. Afterwards, it was centrifuged and dried, and ...

Embodiment 2

[0044] Preparation of a nitrogen-doped hollow amorphous carbon shell sodium metal battery anode material:

[0045] (1) Zinc oxide nanorods

[0046] ZnO nanorods were synthesized by a water bath method.

[0047] The preparation steps are as follows: Zinc acetate dihydrate (C 4 h 6 o 4 ·Zn·2H 2 O, 1.1 g), hexamethylenetetramine (C 6 h 12 N 4 , 0.7 g) was dissolved in 200 mL of deionized water, heated in a water bath at 90 °C for 5 hours, and centrifuged to dry to obtain white zinc oxide powder.

[0048] (2) Preparation of nitrogen-doped hollow amorphous carbon shells

[0049] Dissolve 230 mg of dopamine hydrochloride in 74 ml of alcohol and 34 ml of deionized water, dissolve 170 mg of Tris in 8 ml of alcohol and 4 ml of deionized water, and then slowly add the Tris buffer into the dopamine hydrochloride solution dropwise. Pour the zinc oxide powder in (1) into the above solution, and stir for 12 hours in the dark. Afterwards, it was centrifuged and dried, and annealed ...

Embodiment 3

[0052] Preparation of a nitrogen-doped hollow amorphous carbon shell sodium metal battery anode material:

[0053] (1) Zinc oxide nanorods

[0054] ZnO nanorods were synthesized by a water bath method.

[0055] The preparation steps are as follows: Zinc acetate dihydrate (C 4 h 6 o 4 ·Zn·2H 2 O, 1.1 g), hexamethylenetetramine (C 6 h 12 N 4 , 0.7 g) was dissolved in 200 mL of deionized water, heated in a water bath at 90 °C for 5 hours, and centrifuged to dry to obtain white zinc oxide powder.

[0056] (2) Preparation of nitrogen-doped hollow amorphous carbon shells

[0057] Dissolve 230 mg of dopamine hydrochloride in 74 ml of alcohol and 34 ml of deionized water, dissolve 160 mg of Tris in 8 ml of alcohol and 4 ml of deionized water, and then slowly add the Tris buffer into the dopamine hydrochloride solution dropwise. Pour the zinc oxide powder in (1) into the above solution, and stir for 12 hours in the dark. Afterwards, it was centrifuged and dried, and annealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com