Preparation method of super-hydrophobic sponge capable for efficient oil-water separation

A super-hydrophobic sponge, oil-water separation technology, applied in the field of sponge preparation, can solve the problems of difficult continuous separation, restricting practical and commercial applications, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ① Mix 40 μL curing agent (Dow Corning 184-B solution) with 500 μL PDMS basic component (Dow Corning 184-A solution), stir for 3 minutes, and then dissolve to 50 mL of n-hexane and methanol with a volume ratio of 2:1. After shaking for 3 minutes, a PDMS dilution solution with a concentration of about 1% was obtained and set aside.

[0026] ②Dissolve 5.821g of cobalt nitrate hexahydrate into 40mL of water to obtain solution A for later use.

[0027] ③Sonically dissolve 2.053g of 1-methylimidazole into 50mL of methanol to obtain solution B for later use.

[0028] ④ Add the solution B obtained in step ③ to the solution A prepared in step ② under the condition of stirring, and continue to stir for 10 minutes, then centrifuge the product, wash it with ethanol for 3 times, and then shake and disperse it in ① to prepare The PDMS dilution, set aside.

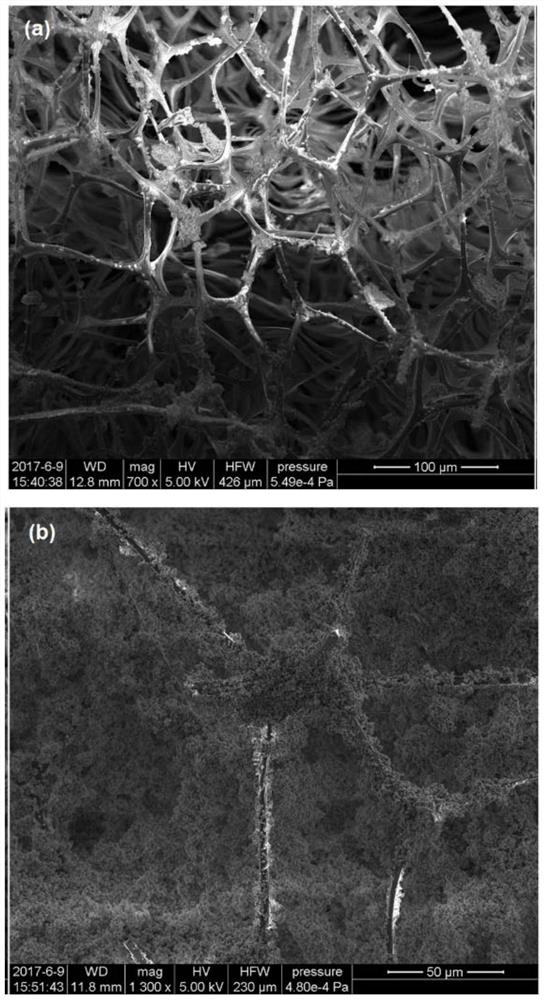

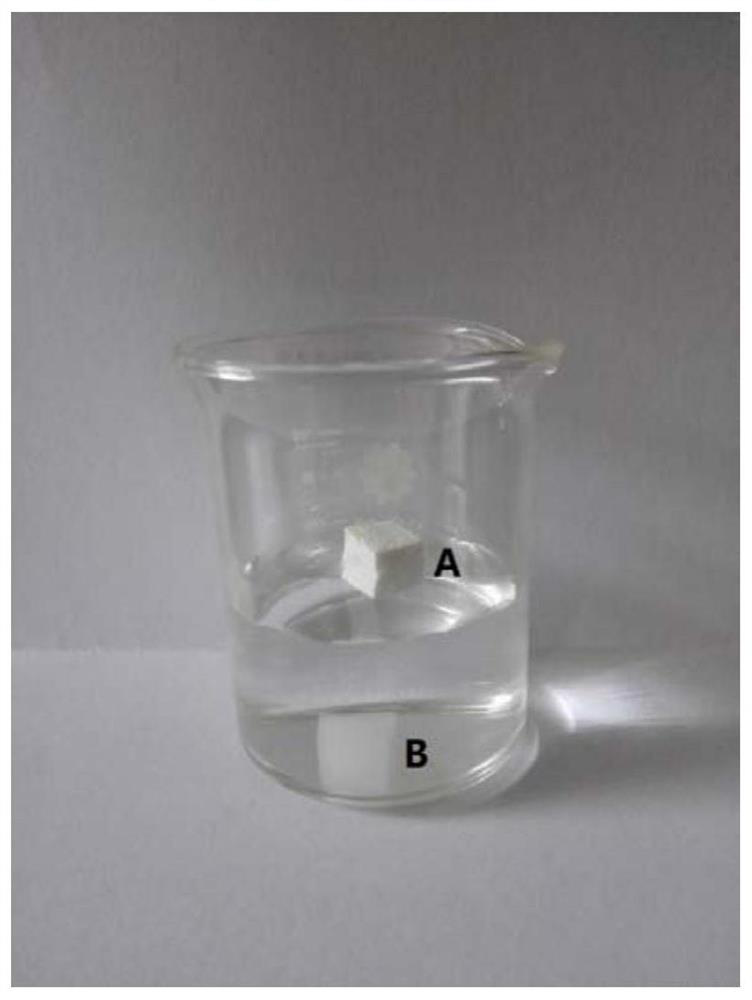

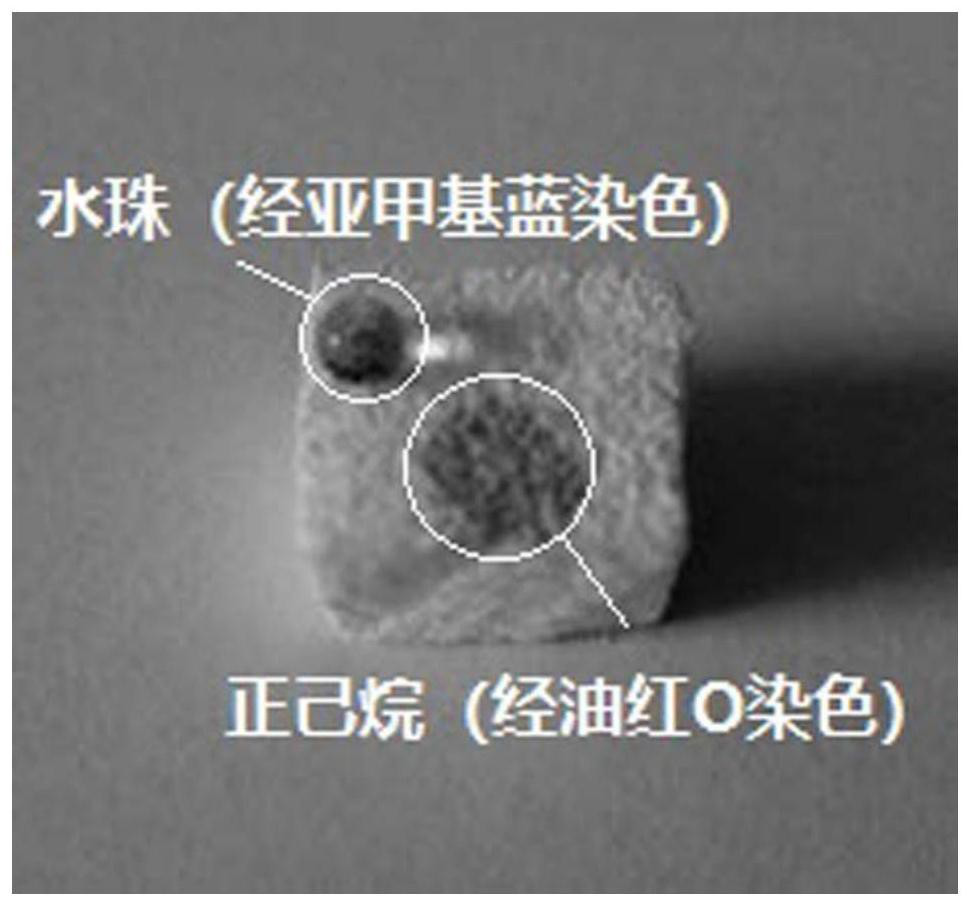

[0029] ⑤Wash the commercially available melamine sponge (1 cubic centimeter) three times with ethanol and deionized water, dry...

Embodiment 2

[0031] ① Mix 50 μL curing agent (Dow Corning 184-B solution) with 500 μL PDMS basic component (Dow Corning 184-A solution), stir for 3 minutes, and then dissolve to 40 mL of n-hexane and methanol with a volume ratio of 1:1. After shaking for 3 minutes, a PDMS dilution solution with a concentration of about 1.36% was obtained and set aside.

[0032] ②Dissolve 3.835g of zinc nitrate hexahydrate into 30mL of water to obtain solution A for later use.

[0033] ③Sonically dissolve 7.088g of benzoimidazole into 60mL of ammonia water to obtain solution B for later use.

[0034] ④ Add the solution B obtained in step ③ to the solution A prepared in step ② under stirring condition, continue to stir for 10 minutes, then centrifuge the product, wash it with ethanol for 3 times, then shake and disperse it in ① to prepare The PDMS dilution, set aside.

[0035]⑤Wash the commercially available melamine sponge (1 cubic centimeter) three times with ethanol and deionized water, dry to constant ...

Embodiment 3

[0037] ① Mix 80 μL curing agent (Dow Corning 184-B solution) with 800 μL PDMS basic component (Dow Corning 184-A solution), stir for 3 minutes, and then dissolve to 50 mL of n-hexane and methanol with a volume ratio of 10:1. After shaking for 3 minutes, a PDMS dilution solution with a concentration of about 1.7% was obtained and set aside.

[0038] ②Dissolve 5.113g of zinc nitrate hexahydrate in 20mL of methanol to obtain solution A for later use.

[0039] ③Sonically dissolve 6.568g of 2-methylimidazole into 40mL of water to obtain solution B for later use.

[0040] ④ Add the solution B obtained in step ③ to the solution A prepared in step ② under the condition of stirring, and continue to stir for 10 minutes, then centrifuge the product, wash it with ethanol for 3 times, and then shake and disperse it in ① to prepare The PDMS dilution, set aside.

[0041] ⑤Wash the commercially available melamine sponge (1 cubic centimeter) three times with ethanol and deionized water, dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com