Preparation method of high-performance calcium sulfate whisker based on inorganic-organic hybrid modification

A calcium sulfate whisker, organic hybrid technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve problems such as lack of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

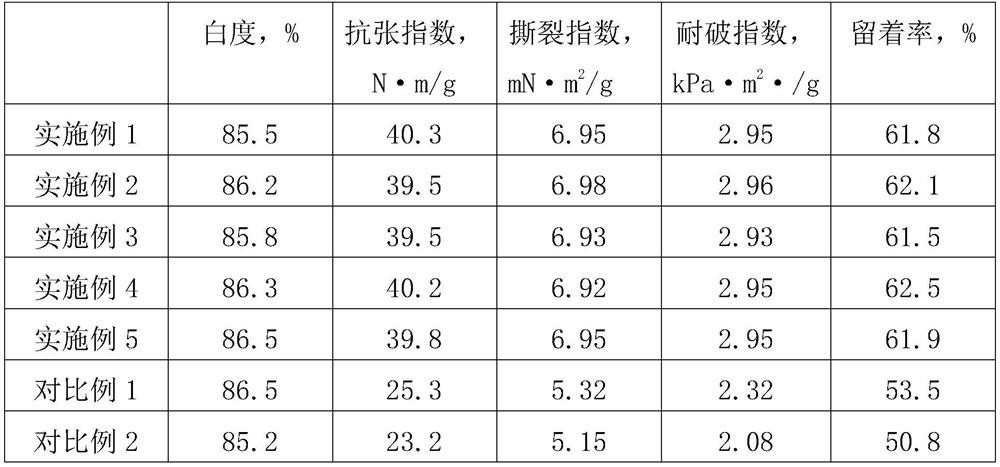

Examples

Embodiment 1

[0024] Grind phosphogypsum and mix with water to control the ratio of material to liquid to 1:4, stir and wash for 10 minutes, then let it settle for precipitation, remove the upper impurity solution, continue to add water to the precipitation for washing, and repeat this for 3-5 times to obtain purified phosphorus Gypsum: Add 100g of purified phosphogypsum to 500g of hot sodium chloride solution at a temperature of 95°C and a concentration of 15wt%, add dropwise a 1mol / L hydrochloric acid solution to adjust the pH of the solution to 2.2, react at a constant temperature for 2 hours, and filter while hot after the reaction , and washing the filtered solid to neutrality, and drying in vacuum to obtain calcium sulfate whiskers;

[0025] Add 2g of zein and 0.65g of gelatin to 10ml of 75wt% acetic acid solution and stir until the solid dissolves, then add 4g of calcium sulfate whiskers, stir at 2000rpm for 30min, filter, and dry the solid to obtain zein alcohol Calcium sulfate whis...

Embodiment 2

[0028] Grind phosphogypsum and mix it with water to control the ratio of material to liquid to 1:4, stir and wash for 20 minutes, then let it settle for precipitation, remove the upper impurity solution, continue to add water to the precipitation for washing, and repeat this for 3-5 times to obtain purified phosphorus Gypsum: Add 200g of purified phosphogypsum to 500g of hot sodium chloride solution at a temperature of 95°C and a concentration of 20wt%, add dropwise 1mol / L hydrochloric acid solution to adjust the pH of the solution to 2.2, react at a constant temperature for 4 hours, and filter while hot after the reaction , and washing the filtered solid to neutrality, and drying in vacuum to obtain calcium sulfate whiskers;

[0029] Add 3g of zein and 0.85g of gelatin to 15ml of 80wt% acetic acid solution and stir until the solid dissolves, then add 4-5g of calcium sulfate whiskers, stir at 5000rpm for 60min, filter, and dry the solid to obtain Calcium sulfate whiskers modif...

Embodiment 3

[0032]Grind phosphogypsum and mix it with water to control the ratio of material to liquid to 1:4, stir and wash for 20 minutes, then let it settle for precipitation, remove the upper impurity solution, continue to add water to the precipitation for washing, and repeat this for 3-5 times to obtain purified phosphorus Gypsum: Add 180g of purified phosphogypsum to 500g of hot sodium chloride solution at a temperature of 95°C and a concentration of 15wt%, add dropwise 1mol / L hydrochloric acid solution to adjust the pH of the solution to 2.2, react at a constant temperature for 3 hours, and filter while hot after the reaction , and washing the filtered solid to neutrality, and drying in vacuum to obtain calcium sulfate whiskers;

[0033] Add 2.5g of zein and 0.7g of gelatin to 15ml of 75wt% acetic acid solution and stir until the solid dissolves, then add 4.5g of calcium sulfate whiskers, stir at 3000rpm for 3h, filter, and dry the solid to obtain Calcium sulfate whiskers modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com