Aramid fiber modification method

A kind of aramid fiber and aramid chopped fiber technology, which can be used in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, textiles and paper making, etc. problems, to achieve the effects of excellent temperature resistance, high aspect ratio, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

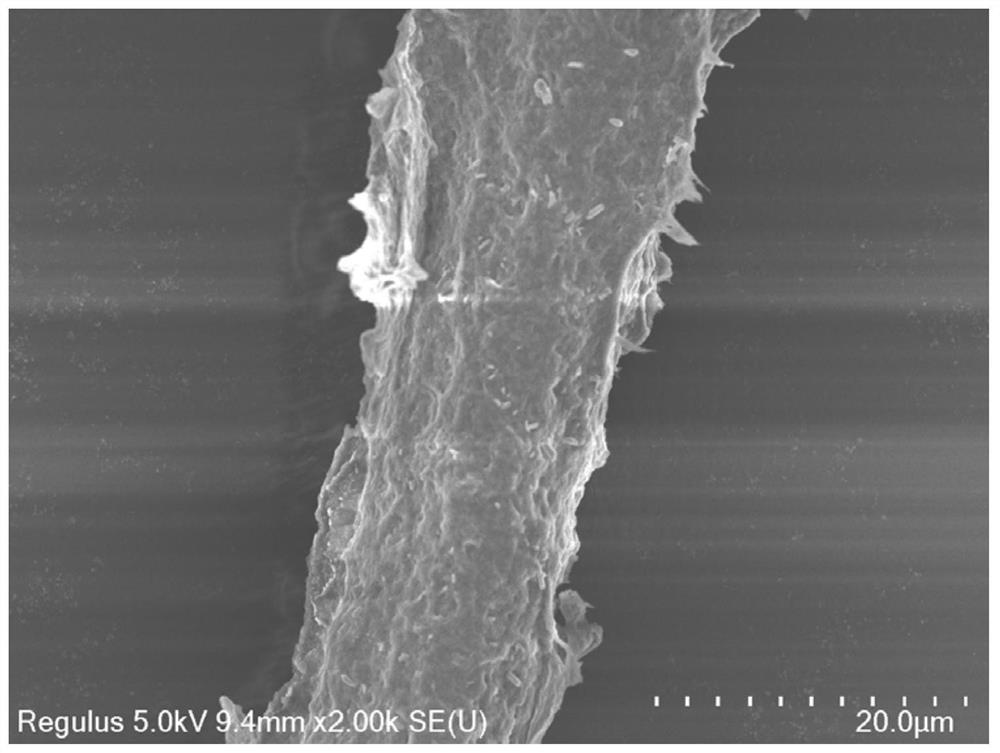

[0033] A method for modifying aramid fibers, using the blending of aramid nanofiber / dimethyl sulfoxide dispersion and aramid chopped fiber / water dispersion to realize in-situ protonation reduction and compounding of aramid nanofibers to prepare aramid fibers Aramid composite fiber covered by nanofiber network; wherein the mass ratio of aramid nanofiber to aramid fiber is 10:90.

[0034] A method for modifying aramid fibers, comprising the steps of:

[0035] Step 1: Prepare aramid chopped fiber / water dispersion: take a certain quality of meta-aramid chopped fiber and one of para-aramid chopped fiber and disperse it in water, stir and disperse it through a standard fiber deflagging machine for 15000r, Obtaining a chopped fiber slurry with a mass concentration of 1.5%;

[0036] Step 2: Prepare aramid nanofiber / dimethyl sulfoxide dispersion: take the recovered para-aramid cloth as raw material in potassium hydroxide / dimethyl sulfoxide / water (KOH / DMSO / H 2 O) a deprotonation react...

Embodiment 2

[0040] A method for modifying aramid fibers, using the blending of aramid nanofiber / dimethyl sulfoxide dispersion and aramid chopped fiber / water dispersion to realize in-situ protonation reduction and compounding of aramid nanofibers to prepare aramid fibers An aramid composite fiber covered by a nanofiber network; wherein the mass ratio of the aramid nanofiber to the aramid fiber is 20:80.

[0041] A method for modifying aramid fibers, comprising the steps of:

[0042] Step 1: Prepare aramid chopped fiber / water dispersion: take a certain quality of meta-aramid chopped fiber and one of para-aramid chopped fiber and disperse it in water, stir and disperse it through a standard fiber deflagging machine for 15000r, Obtaining a chopped fiber slurry with a mass concentration of 1.2%;

[0043] Step 2: Prepare aramid nanofiber / dimethyl sulfoxide dispersion: take the recycled para-aramid waste silk as raw material in potassium hydroxide / dimethyl sulfoxide / water (KOH / DMSO / H 2 O) a de...

Embodiment 3

[0047] A method for modifying aramid fibers, using the blending of aramid nanofiber / dimethyl sulfoxide dispersion and aramid chopped fiber / water dispersion to realize in-situ protonation reduction and compounding of aramid nanofibers to prepare aramid nanofibers Aramid composite fibers covered by fiber network; wherein the mass ratio of aramid nanofibers to aramid fibers is 30:70.

[0048] A method for modifying aramid fibers, comprising the steps of:

[0049] Step 1: Prepare aramid chopped fiber / water dispersion: take a certain quality of meta-aramid chopped fiber and one of para-aramid chopped fiber and disperse it in water, stir and disperse it through a standard fiber deflagging machine for 15000r, Obtaining a chopped fiber slurry with a mass concentration of 1.0%;

[0050] Step 2: Prepare aramid nanofiber / dimethyl sulfoxide dispersion: take the recycled para-aramid yarn waste as raw material in potassium hydroxide / dimethyl sulfoxide / water (KOH / DMSO / H 2 O) a deprotonatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com