Flexible conductive film and preparation method thereof

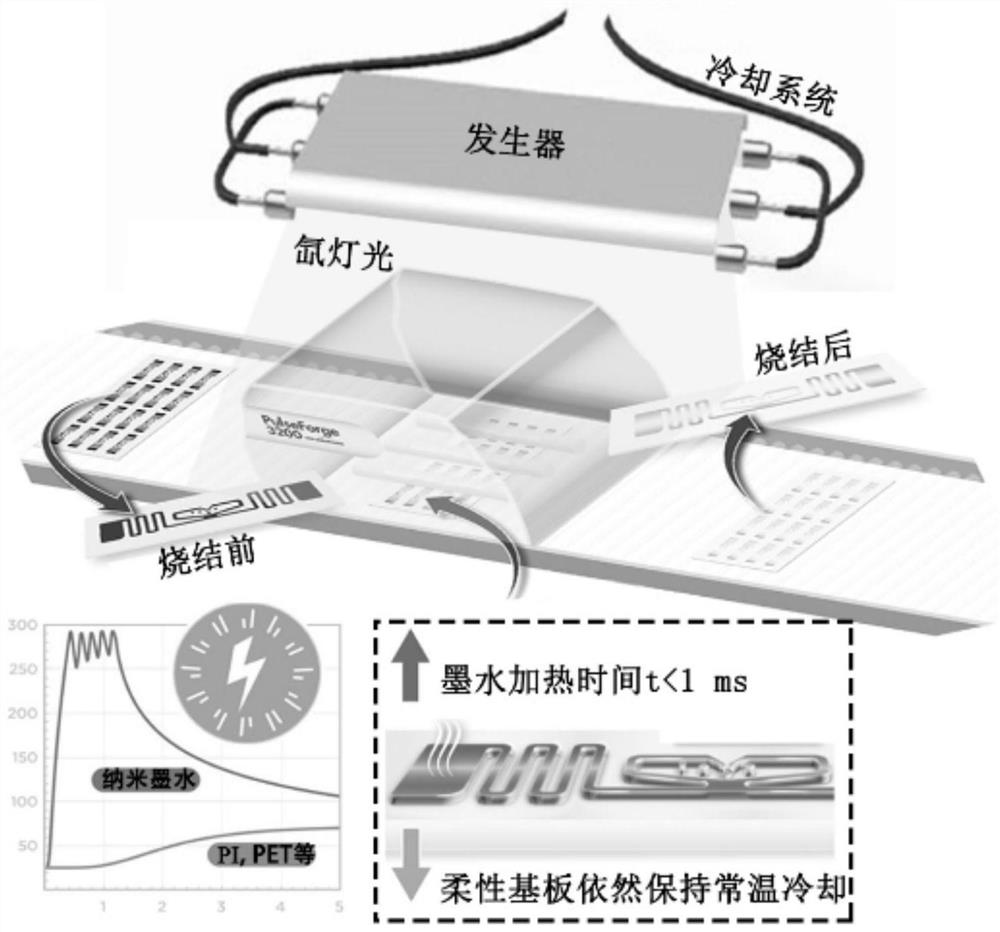

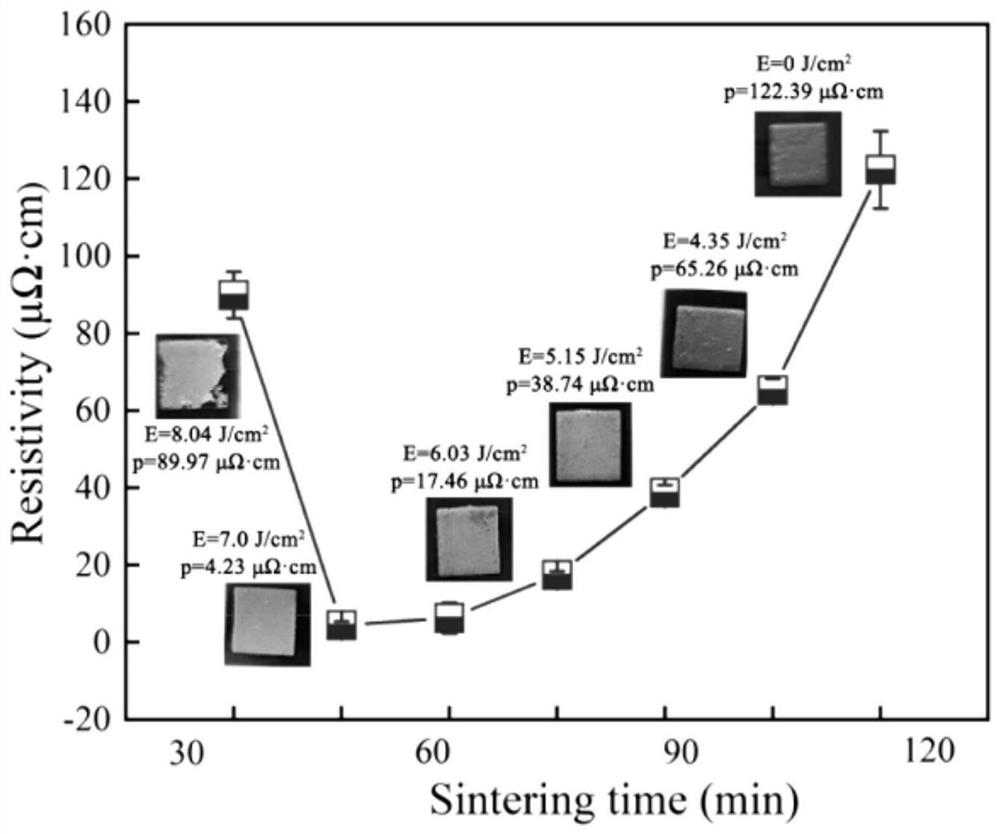

A flexible conductive and thin film technology, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of shortening the sintering time of nano-inks, high cost of conductive films, and electrical problems. Migrate conductivity and other issues to achieve the effect of avoiding substrate damage, dense tissue and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a flexible conductive film, comprising:

[0044] Step 1: Synthesis of metal nanoparticles (gold, silver, copper, nickel, etc.)

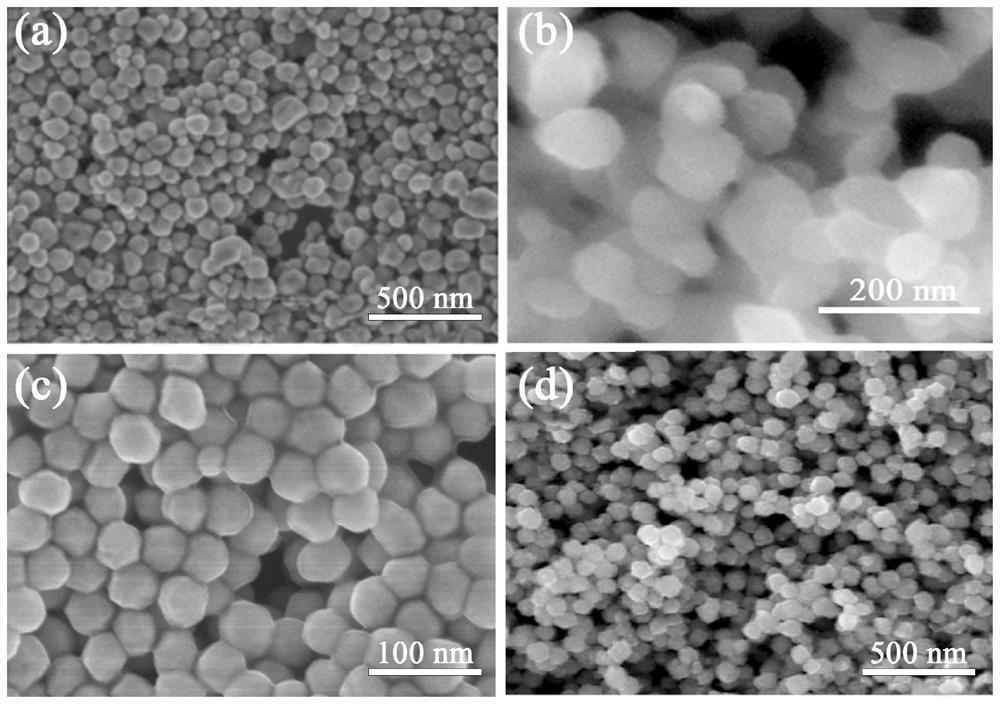

[0045] Add an appropriate amount of metal salt to the organic solvent, mix well, stir continuously, heat to 50~80°C, and obtain solution A after the metal salt is completely dissolved; add appropriate amount of reducing agent and protective agent to the organic solvent, mix evenly, stir continuously, and heat to 50~80°C, after completely dissolving to obtain solution B; add freshly prepared solution A to freshly prepared solution B, and keep stirring the mixed solution, heat to 60~90°C, and react for 60~90 min to obtain Metal nanoparticle dispersion: the metal nanoparticle dispersion is cooled to room temperature and then centrifuged, and washed and centrifuged multiple times with one or more mixed washing solutions of absolute ethanol, acetone, and deionized water. Add a certain amount of centrifuged-cleaned metal nano...

Embodiment 1

[0065] (1) Add an appropriate amount of metal salt to the organic solvent, mix well, stir continuously, heat to 50°C, and obtain solution A after the metal salt is completely dissolved; add an appropriate amount of reducing agent and protective agent to the organic solvent, mix evenly, stir continuously, and heat to 50°C, solution B was obtained after complete dissolution. The freshly prepared solution A was added to the freshly prepared solution B, and the mixed solution was stirred continuously, heated to 60 °C, and reacted for 60 min to obtain the metal nanoparticle dispersion.

[0066] (2) Cool the metal nanoparticle dispersion obtained in step (1) to room temperature and then centrifuge it, and wash it several times with absolute ethanol, acetone, or a mixture of two or more of them in ionized water , centrifugal. Weigh metal nanoparticles with a solid content of 50% and organic solvents (ethyl cellulose, ethyl acetate, 1-2-propanediol, defoamer, terpineol, etc. in a mas...

Embodiment 2

[0073] (1) Add an appropriate amount of metal salt to the organic solvent, mix well, stir continuously, heat to 50°C, and obtain solution A after the metal salt is completely dissolved; add an appropriate amount of reducing agent and protective agent to the organic solvent, mix evenly, stir continuously, and heat to 50°C, solution B was obtained after complete dissolution. The freshly prepared solution A was added to the freshly prepared solution B, and the mixed solution was stirred continuously, heated to 60 °C, and reacted for 60 min to obtain the metal nanoparticle dispersion. Among them, metal salts are

[0074] (2) Cool the metal nanoparticle dispersion obtained in step (1) to room temperature and then centrifuge it, and wash it several times with absolute ethanol, acetone, or a mixture of two or more of them in ionized water , centrifugal. Weigh metal nanoparticles with a solid content of 50% and an organic solvent (ethyl cellulose, ethyl acetate, 1-2-propylene glycol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com