Cobalt diselenide@porous nitrogen-doped carbon nano composite material, potassium ion battery and preparation method thereof

A nanocomposite material, cobalt diselenide technology, which is applied in the field of electrode materials for potassium-ion secondary batteries, can solve the problems of synthesis methods and performance differences, and achieve the effects of simple methods, alleviating volume expansion, and improving Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Quickly inject 2 mL of an aqueous solution containing 58 mg of cobalt nitrate and 1 mg of cetyltrimethylammonium bromide (CTAB) into 14 mL of an aqueous solution containing 908 mg of 2-methylimidazole, and stir vigorously at room temperature for 20 min, then wash the precipitate repeatedly with ethanol At least 6 times, and then vacuum-dried overnight at room temperature to obtain purple ZIF-67 nanocubes; ZIF-67 was calcined for 1 h at a rate of 1 °C / min to 650 °C under an argon atmosphere to obtain a black powder called cobalt@porous Nitrogen-doped carbon; Cobalt@porous nitrogen-doped carbon and selenium powder were placed in two porcelain boats at a mass ratio of 1:10, and the selenium powder porcelain boat was placed upstream of the tube furnace. Under selenization for 3 hours, cobalt diselenide@porous nitrogen-doped carbon nanocubes were obtained;

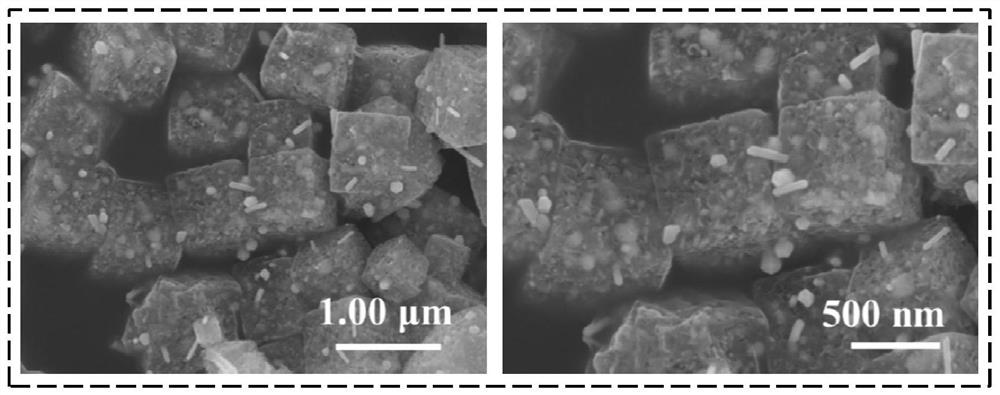

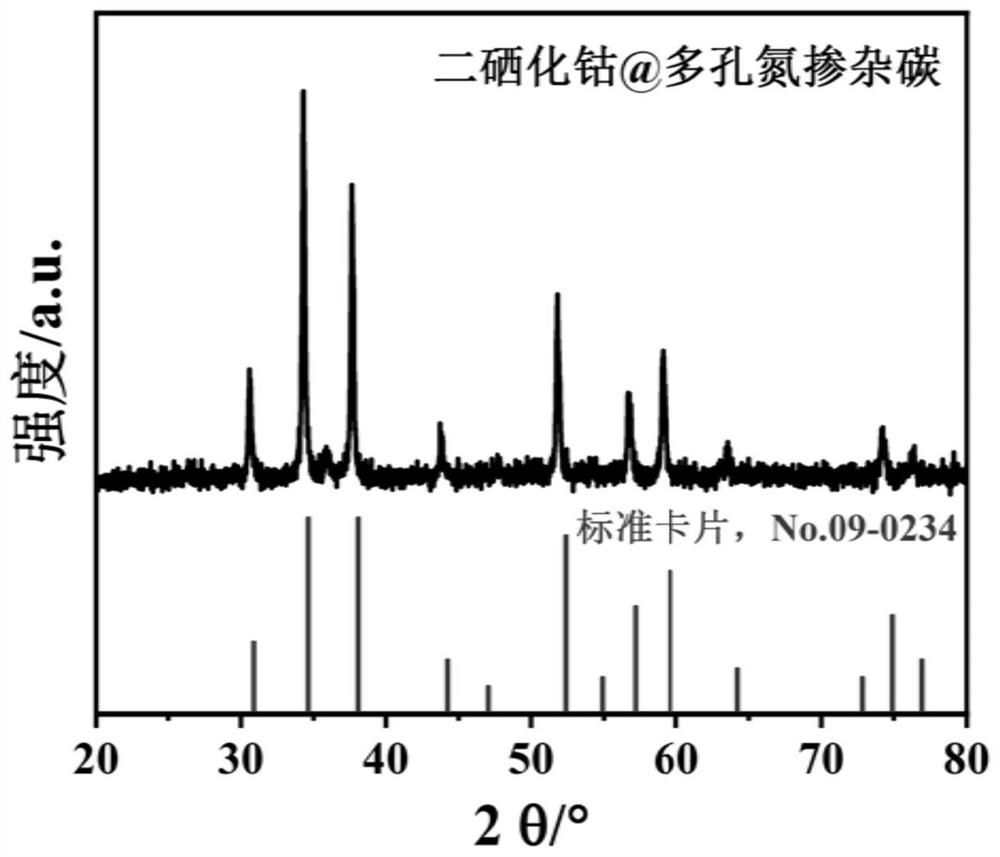

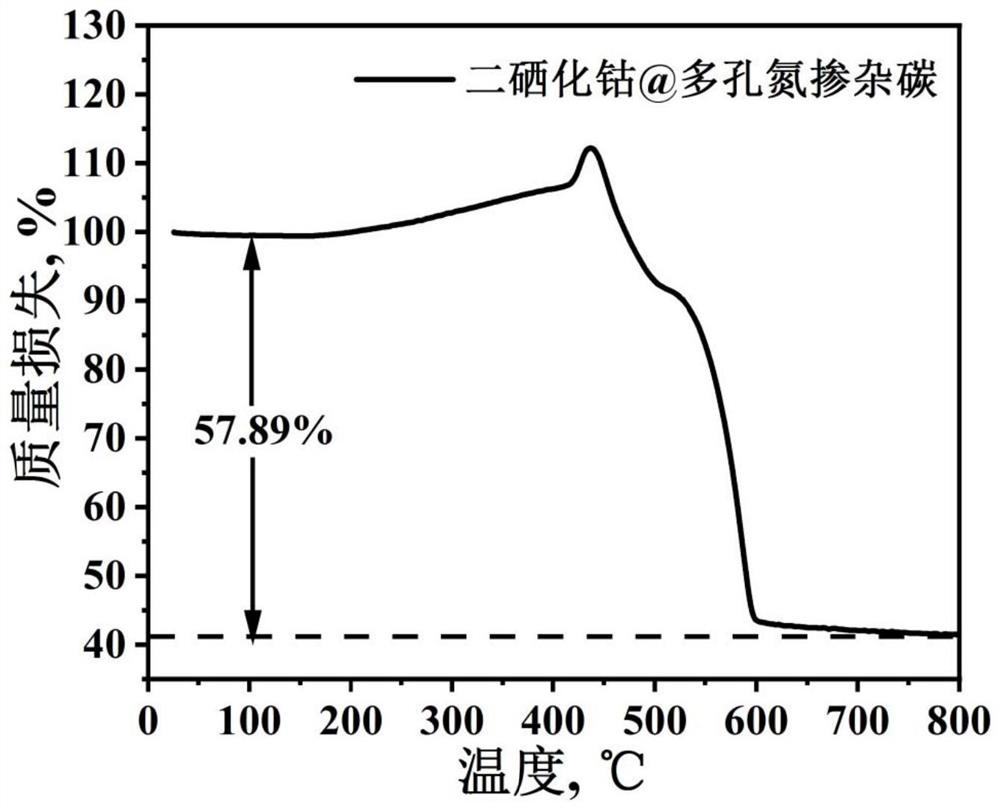

[0045] figure 1 It is the SEM image of the cobalt diselenide@porous nitrogen-doped carbon nanomaterial prepared in th...

Embodiment 2

[0052] Quickly inject 2 mL of an aqueous solution containing 58 mg of cobalt sulfate and 1 mg of cetyltrimethylammonium bromide (CTAB) into 14 mL of an aqueous solution containing 908 mg of 2-methylimidazole, and stir vigorously at room temperature for 20 minutes, then wash the precipitate repeatedly with ethanol At least 6 times, and then vacuum-dried overnight at room temperature to obtain purple ZIF-67 nanocubes; ZIF-67 was calcined for 1 h at a rate of 2 °C / min to 750 °C under an argon atmosphere to obtain a black powder called cobalt@porous Nitrogen-doped carbon; Cobalt@porous nitrogen-doped carbon and selenium powder were placed in two porcelain boats at a mass ratio of 1:10, and the selenium powder porcelain boat was placed upstream of the tube furnace. Under selenization for 3 hours, cobalt diselenide@porous nitrogen-doped carbon nanocubes were obtained;

[0053] Weigh 0.4g of cobalt diselenide@porous nitrogen-doped carbon nanomaterial prepared above, 0.05g of acetylen...

Embodiment 3

[0055] Quickly inject 2 mL of an aqueous solution containing 58 mg of cobalt chloride and 1 mg of cetyltrimethylammonium bromide (CTAB) into 14 mL of an aqueous solution containing 908 mg of 2-methylimidazole, stir vigorously at room temperature for 20 min, and then wash repeatedly with ethanol Precipitate at least 6 times, and then dry overnight at room temperature under vacuum to obtain purple ZIF-67 nanocubes; ZIF-67 was calcined for 1 h at a rate of 3 °C / min to 750 °C under an argon atmosphere to obtain a black powder of cobalt@ Porous nitrogen-doped carbon; put cobalt@porous nitrogen-doped carbon and selenium powder in two porcelain boats at a mass ratio of 1:10, and place the selenium powder porcelain boat in the upstream of the tube furnace. Selenization at ℃ for 3 hours to obtain cobalt diselenide@porous nitrogen-doped carbon nanocubes;

[0056] Weigh 0.4g of cobalt diselenide@porous nitrogen-doped carbon nanomaterial prepared above, 0.05g of acetylene black (conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com