High-strength modified plastic processing method

A processing method and high-strength technology, applied in the field of plastics, can solve the problems of physical and mechanical performance degradation, poor light and thermal stability, and affect operation, etc., to achieve the effects of improving flow properties, easy extrusion molding, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

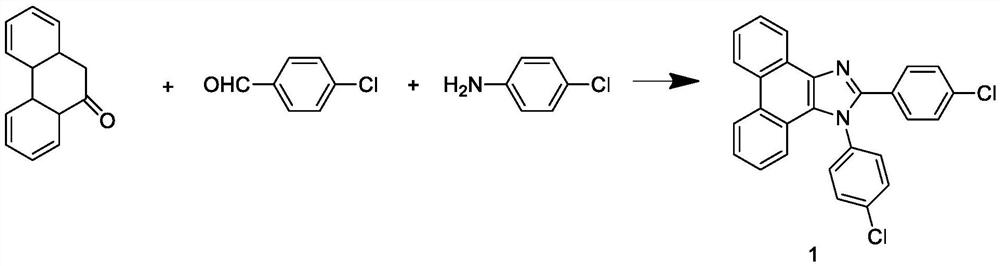

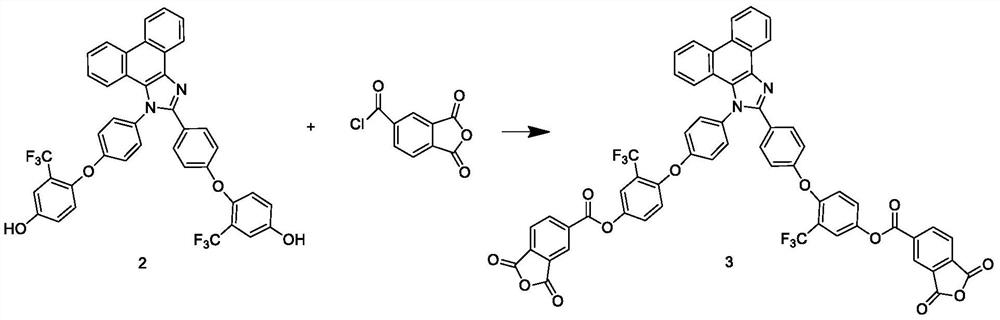

[0042] Preparation of modified coupling agent:

[0043]Step S1, under the protection of nitrogen, add 60.5mmol phenanthrenequinone, 60.5mmol 4-chloroaniline, 241mmol ammonium acetate, 60.5mmol 4-chlorobenzaldehyde, 3.1mL glacial acetic acid and 250mL acetonitrile into a three-necked flask, stir well, and heat Refluxing reaction at 75°C for 20h, cooling to room temperature, pouring the product into methanol, stirring and suction filtration, washing the filter cake with methanol for 3 times, and drying at 60°C for 10h to obtain intermediate 1;

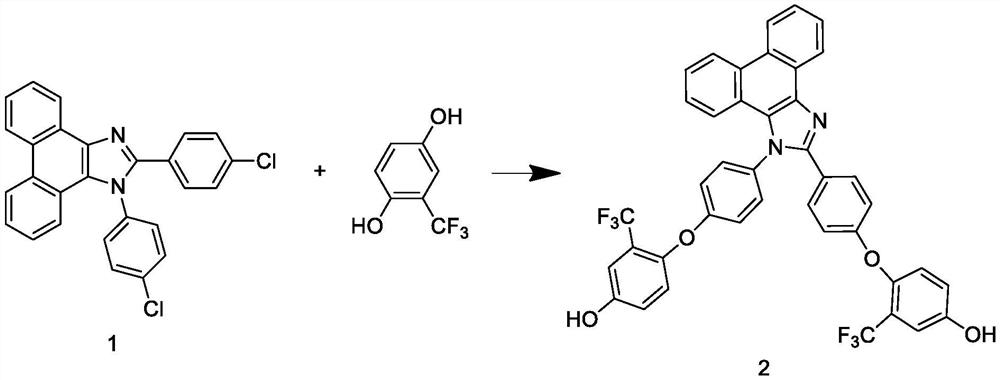

[0044] Step S2, under the protection of nitrogen, add 53.2mmol of intermediate 1, 106.4mmol of 1,4-diol trifluorotoluene, 106.4mmol of potassium carbonate and 151mL of DMAC into a three-necked flask, stir evenly, heat to 145°C for 11h, and cool After reaching room temperature, the product was poured into deionized water, stirred, suction filtered, the filter cake was washed twice with methanol, recrystallized with ethyl acetate, and drie...

Embodiment 2

[0049] Preparation of modified coupling agent:

[0050] Step S1, under the protection of nitrogen, add 60.8mmol phenanthrenequinone, 60.8mmol 4-chloroaniline, 241.2mmol ammonium acetate, 60.7mmol 4-chlorobenzaldehyde, 3.3mL glacial acetic acid and 253mL acetonitrile into a three-necked flask, stir well, and heat to Reflux at 78°C for 21 hours, cool to room temperature, pour the product into methanol, stir and filter with suction, wash the filter cake with methanol for 3 times, and dry at 60°C for 11 hours to obtain intermediate 1;

[0051] Step S2, under the protection of nitrogen, add 53.8mmol of intermediate 1, 107.2mmol of 1,4-diol trifluorotoluene, 107.5mmol of potassium carbonate and 153mL of DMAC into a three-necked flask, stir evenly, and heat to 145°C for 11h. Cool to room temperature, pour the product into deionized water, stir, filter with suction, wash the filter cake twice with methanol, recrystallize with ethyl acetate, and dry at 60°C for 11 hours to obtain inter...

Embodiment 3

[0056] Preparation of modified coupling agent:

[0057] Step S1, under the protection of nitrogen, add 61mmol phenanthrenequinone, 61mmol 4-chloroaniline, 241.5mmol ammonium acetate, 61mmol 4-chlorobenzaldehyde, 3.5mL glacial acetic acid and 255mL acetonitrile into a three-necked flask, stir well, and heat to 82 Reflux at ℃ for 22 hours, cool to room temperature, pour the product into methanol, stir and filter with suction, wash the filter cake with methanol for 4 times, and dry at 60℃ for 12 hours to obtain intermediate 1;

[0058] Step S2, under the protection of nitrogen, add 54mmol of intermediate 1, 108mmol of 1,4-diol trifluorotoluene, 108mmol of potassium carbonate and 155mL of DMAC into a three-necked flask, stir evenly, heat to 145°C for 12h, cool to room temperature, The product was poured into deionized water, stirred, suction filtered, the filter cake was washed 3 times with methanol, recrystallized with ethyl acetate, and dried at 60°C for 12 hours to obtain inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com