Coating type catalyst composition, catalytic filter tube and preparation method thereof

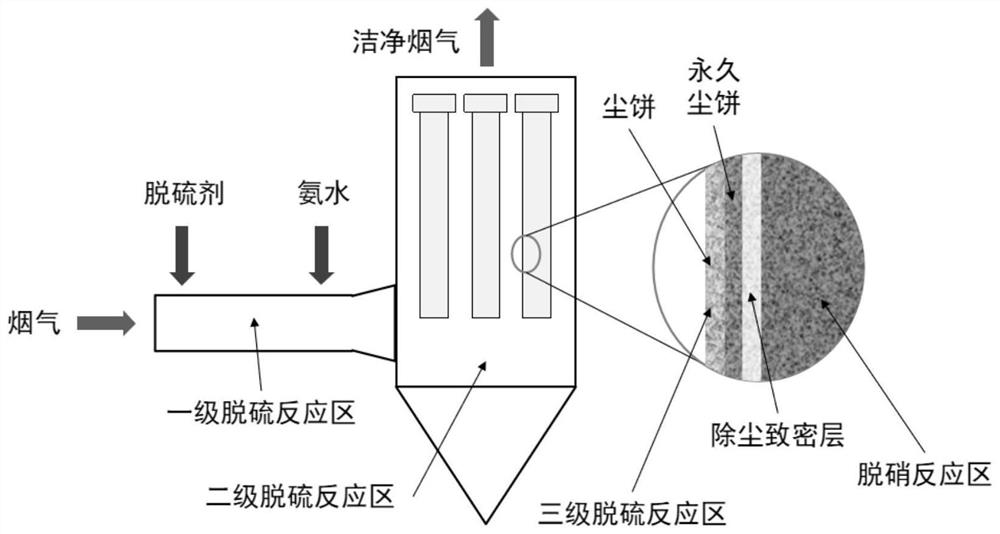

A catalyst and coating-type technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as blowing off, large air flow, and difficult bonding of catalyst slurry to achieve low filtration resistance , High catalytic efficiency, increase the effect of catalytic removal of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] The second aspect of the present invention provides a method for preparing the coated catalyst composition according to the present invention, comprising the steps of mixing and ball milling the components of the coated catalyst composition.

[0105] In some specific embodiments, the preparation method includes the following steps:

[0106] dissolving the catalytically active component and the catalytic assistant in water, and adjusting the pH value with a pH regulator to obtain a precursor solution;

[0107] adding a dispersant, a defoamer and a binder to the precursor solution to obtain a premix;

[0108] adding a carrier to said premix to obtain a mixed precursor;

[0109] After the mixed precursor is ball milled, a plasticizer is added to obtain a coated catalyst composition.

[0110] In some specific embodiments, the preparation of the precursor solution includes the following steps: dissolving the weighed metal salt of the catalytic active component and the meta...

Embodiment 1

[0139] (1) Preparation of coated catalyst composition

[0140] 1) Dissolve 2.05kg of the active catalyst component ammonium metavanadate and 4.06kg of the catalytic promoter ammonium paratungstate in 70kg of deionized water at about 55°C, cool to room temperature, and then add 2kg dropwise with a mass concentration of 25-28% ammonia water to adjust the pH value to 9-10 to obtain mixed solution A (precursor solution);

[0141] 2) The quantitatively weighed dispersant polyethylene glycol 3kg, the defoamer isopropyl alcohol 0.5kg and the binding agent pH are 8, and the silica sol 10kg with a solid content of 30% is added in the above-mentioned mixed solution A, and the Stir under emulsifier for 10min to obtain mixed solution B (premix);

[0142] 3) Weighing 60 kg of quantitative anatase-type titanium dioxide and adding it to the above mixed solution B, mechanically stirring for 15 minutes, and fully mixing to obtain mixed solution C (mixed precursor);

[0143] 4) Place the abov...

Embodiment 2

[0149] (1) Preparation of coated catalyst composition

[0150] 1) Dissolve 1.05kg of the catalyst active components ammonium metavanadate and 3.03kg of ferric nitrate in 70kg of deionized water at about 55°C, cool to room temperature, then add 1.5kg of oxalic acid dropwise to adjust the pH value to 1-2 , to obtain mixed solution A (precursor solution);

[0151] 2) The quantitatively weighed dispersant polyethylene glycol 2.5kg, the defoamer isopropanol 0.5kg and the binding agent pH are 3, and the silica sol 10kg with a solid content of 30% is added in the above-mentioned mixed solution A. Stir for 10 min under a shear emulsifier to obtain a mixed solution B (premix);

[0152] 3) Weighing 60 kg of quantitative anatase-type titanium dioxide and adding it to the above mixed solution B, mechanically stirring for 15 minutes, and fully mixing to obtain mixed solution C (mixed precursor);

[0153] 4) Place the above mixed solution in a ball mill jar, mill at 800 rpm for 100 min, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com