Natural antibiotic-replacing feed additive and preparation method thereof

A feed additive, a natural technology, applied in the field of natural antibacterial feed additives and its preparation, can solve the problems of large usage, loss of antibacterial and bactericidal ingredients, etc., achieve nutritional balance, improve slow-release performance, and improve the effect of antibacterial and bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

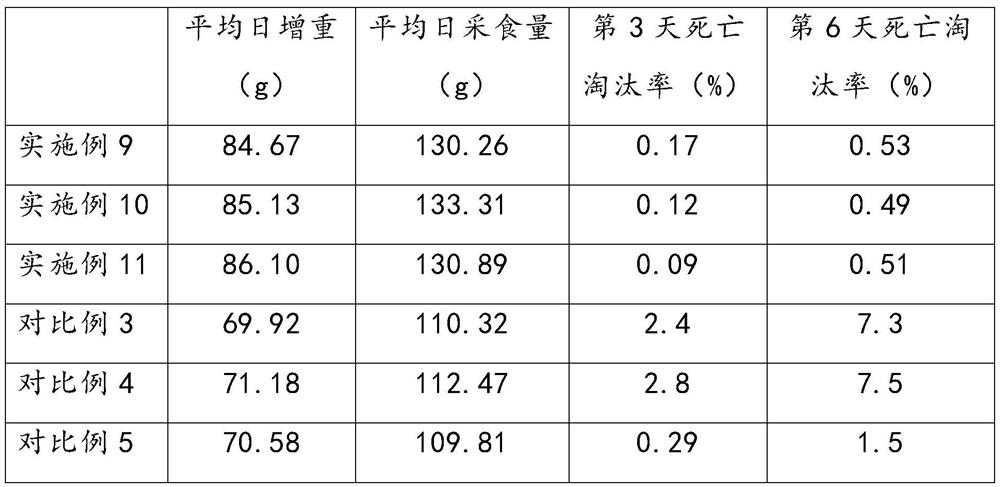

Examples

Embodiment 1

[0030] Ginger extract is made through the following steps:

[0031] After washing the ginger slices, dry them in an oven at 60°C for 9 hours to obtain dried ginger slices; grind the dried ginger slices with a pulverizer to obtain ginger powder; mix ginger powder and ethanol at a mass ratio of 1:45, Stir in a water bath at ℃ for 2 hours to obtain a ginger extract; condense the ginger extract by rotary evaporation at 65 °C to one-tenth of the original volume to obtain the ginger extract.

Embodiment 2

[0033] Scutellaria baicalensis extract is made through the following steps:

[0034] Wash and chop Scutellaria baicalensis, mix according to the mass ratio of Scutellaria baicalensis and water 1:9, heat to boiling, keep warm for 1 hour, keep warm at 70°C for 4 hours, filter to obtain the filtrate, repeat the above operation on the filter residue, and finally combine the filtrate, When the filtrate is concentrated to one-fifth of the original liquid volume, add ethanol to the original liquid volume, ultrasonically disperse for 40 minutes, let stand for 30 minutes, filter, obtain the filtrate and concentrate it to one-fifth of the original liquid volume, repeat the above The operation was performed twice, and when the finally obtained filtrate was concentrated to one-fifth of the original liquid volume, the pH value was adjusted to 1 with citric acid, kept at 60° C. for 3 hours, filtered, and dried to obtain the Scutellaria baicalensis extract.

Embodiment 3

[0036] Core particles are made by the following steps:

[0037]Step A, first 50 parts by weight of wine lees are subjected to steam explosion pretreatment; the treatment intensity of steam explosion is 4MPa, and the treatment time is 3min, thereby reducing the fiber content in wine lees; wine lees after explosion, 17 parts by weight of wheat bran and After mixing 9 parts by weight of rapeseed meal, a premix is obtained, and mixed bacteria and compound enzymes are added to the premix for solid-state anaerobic fermentation; the fermentation conditions are: material-to-water ratio 1:1, temperature 28°C, inoculation amount of mixed bacteria For 0.05% intervening mixture weight, compound enzyme addition 0.05% intervening mixture weight, fermentation time is 7 days, obtains the premix after fermentation, and described mixed bacterium is aspergillus niger and candida utilis according to mass ratio 2: 0.5 for a mixed combination, the strains used are the probiotics allowed to be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com