Solar cell array interconnection material and preparation method thereof

A technology for solar cell arrays and interconnecting materials, applied in the field of solar cells, can solve problems such as defects in electroplated metal layers, atomic oxygen erosion, coating cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

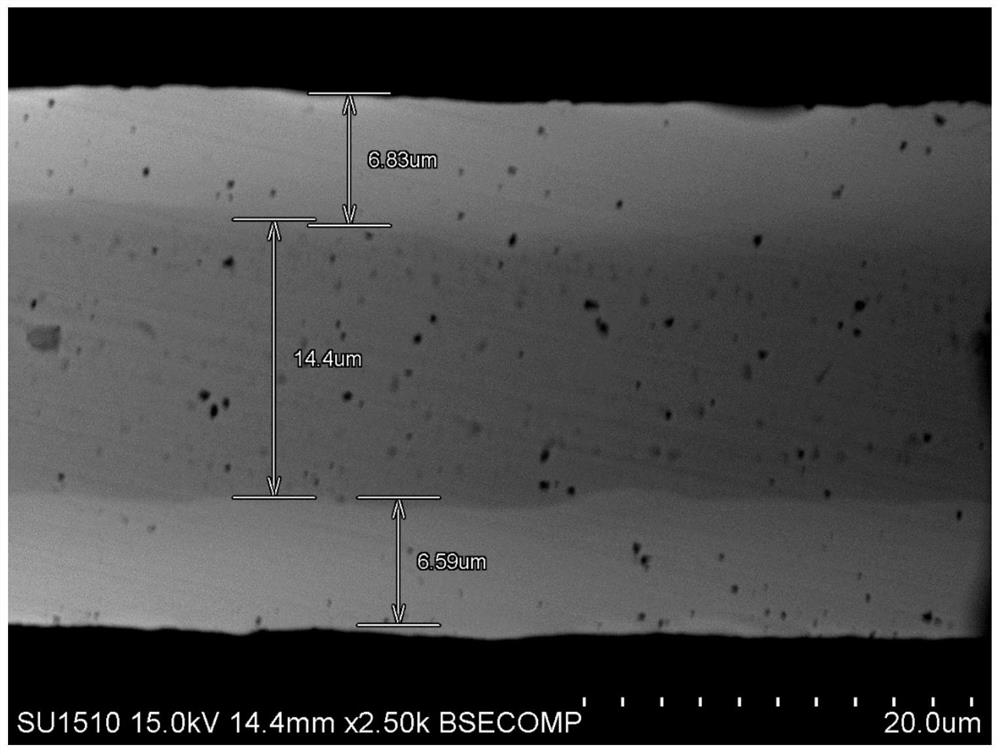

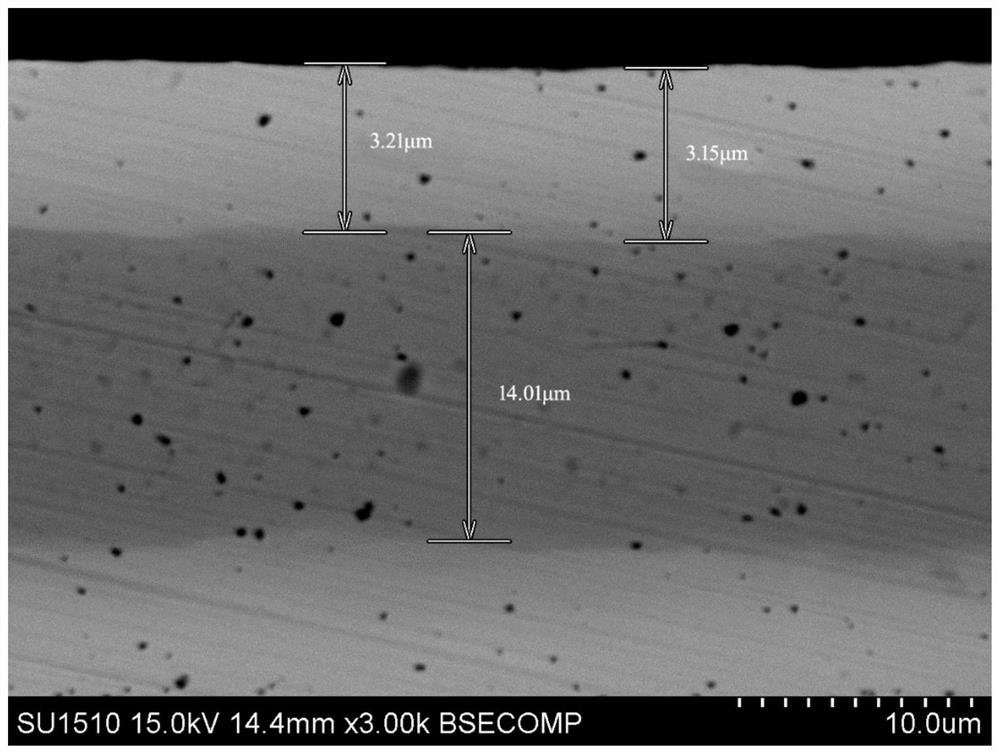

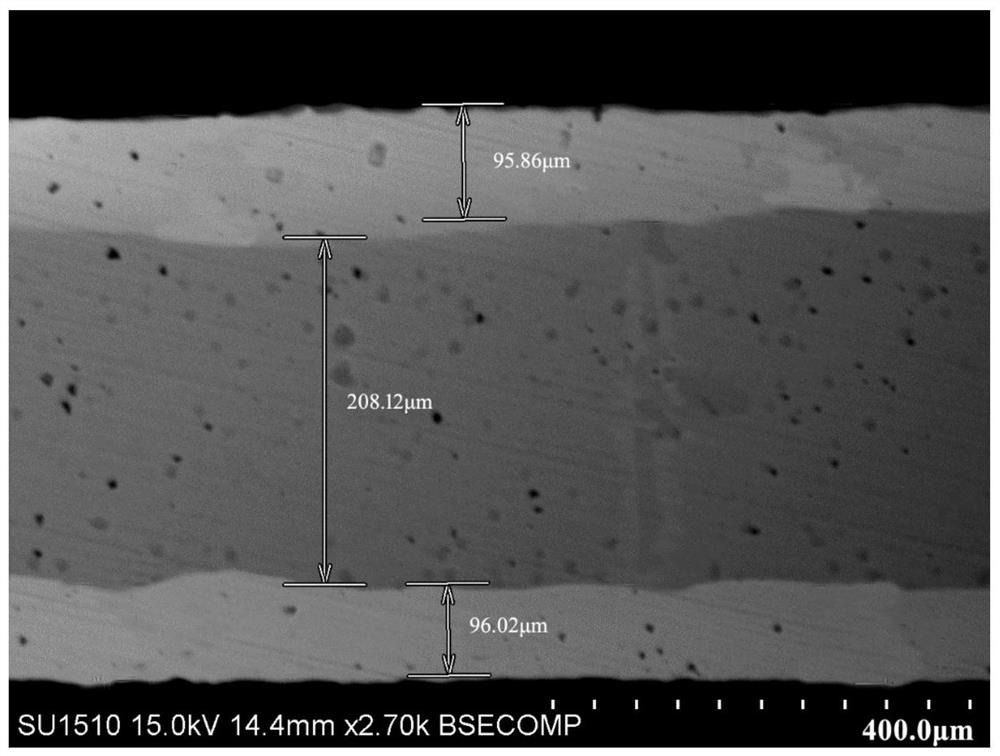

[0036] The present invention also provides a method for preparing the above solar cell array interconnection material, comprising: S1) laminating the first gold-silver alloy plate, the silver plate, and the second gold-silver alloy plate and performing hot-pressing diffusion connection to obtain a composite material ; The mass concentration of the silver element in the first gold-silver alloy plate and the second gold-silver alloy plate is independently 0.001%-0.005%; S2) rolling the composite material to obtain a solar cell array interconnection material.

[0037] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0038]In the present invention, the thicknesses of the first gold-silver alloy plate and the second gold-silver alloy plate are independently 1-2 mm; the first gold-silver alloy plate and the second gold-silver alloy plate are preferably prepared by cold rolling To obtain, specifica...

Embodiment 1

[0047] a) Vacuum smelting of gold and silver to obtain a gold-silver alloy ingot (8×100×200mm), the composition mass percentage is: Au99.995%, Ag 0.005%; the melting temperature is 1100°C.

[0048] b) Rolling of gold and silver alloy ingots: cold rolling into plates to a thickness of 1 mm; the specific rolling process of rolling with a reduction of 20% in each pass is 8.0-7.0-6.0-5.0-4.0-3.0-2.0-1.0.

[0049] c) Equal angular rolling of pure silver (final rolling to 2.14mm thick): equal angular rolling temperature 400°C, holding time 1 hour, processing speed 1mm / s; final rolling reduction 10%; channel gap 1.0mm; the angle between the two channels of the mold is 120°, and the inner arc radius of the channel is 2mm (the arc angle is 65°).

[0050] d) Cutting: Cut the gold-silver alloy plate and pure silver plate to 70×70mm.

[0051] e) Pretreatment: Sand the surface of the cut gold-silver alloy plate and pure silver plate with sandpaper, clean it with alcohol, and dry it with c...

Embodiment 2

[0057] a) Vacuum smelting of gold and silver to obtain a gold-silver alloy ingot (8×100×200mm), the composition mass percentage is: Au99.999%, Ag 0.001%; the melting temperature is 1150°C.

[0058] b) Rolling of gold and silver alloy ingots: cold rolling into plates to a thickness of 1mm; the reduction in each pass is 20%, and the specific rolling process is 8.0-7.0-6.0-5.0-4.0-3.0-2.0-1.0 .

[0059] c) Equal angular rolling of pure silver (final rolling to 4.4mm thick): equal angular rolling temperature 400°C, holding time 1 hour, processing speed 1mm / s; final rolling reduction 10%; channel gap 1.0mm; the angle between the two channels of the mold is 120°, and the inner arc radius of the channel is 2mm (the arc angle is 65°).

[0060] d) Cutting: Cut the gold-silver alloy plate and pure silver plate to 100×100mm.

[0061] e) Pretreatment: Sand the surface of the cut gold-silver alloy plate and pure silver plate with sandpaper, clean it with alcohol, and dry it with cold a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com