Composite bond grinding wheel for large-size silicon carbide substrate processing and preparation method thereof

A technology of silicon carbide substrate and composite binder, which is applied in the direction of bonded grinding wheels, metal processing equipment, manufacturing tools, etc., to achieve good homogeneity, solve processing problems, and have strong grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

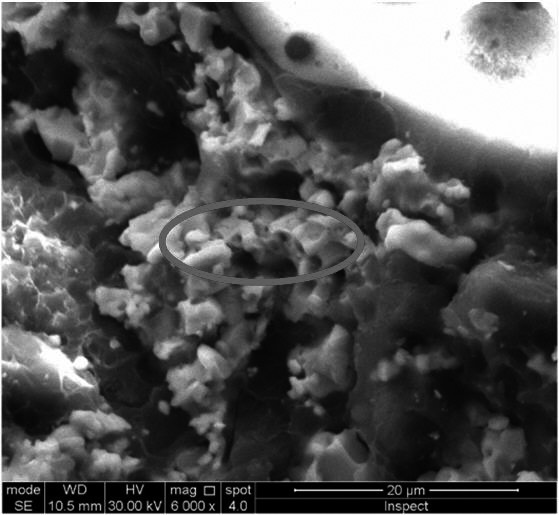

Image

Examples

Embodiment 1

[0032] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size 325 / 400, TTI76 diamond abrasive 25%, mixed powder 32%, polyphenylene sulfide 20%, zinc oxide whisker 15%, SG abrasive 8%.

[0033]The mixed powder is obtained through the following process: in terms of mass percentage, 62% of zinc powder, 18.2% of copper powder, 2.2% of aluminum powder, and 6.6% of iron powder are mixed with metal powder, and a high-frequency vibrating screen is used at 2000 times / min Vibrate for 30 minutes, then add 11% graphite, and then put the mixture into a liquid nitrogen cooling wall breaking machine with a rotation speed of 40,000rpm (manufacturer: Domon wall breaking machine model: LM-388, the same below), and the mass rati...

Embodiment 2

[0044] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size M34 / 42, TTI77.5 diamond abrasive 45%, mixed powder 25%, polyphenylene sulfide 8%, zinc oxide whisker 12%, SG abrasive 10%.

[0045] The mixed powder is obtained through the following process: in terms of mass percentage, 70% of zinc powder, 15% of copper powder, 0.5% of aluminum powder, and 1.5% of iron powder are used to vibrate at 2000 times / min for 10 min using a high-frequency vibrating sieve, and then Add 13% graphite, then put the mixture into a liquid nitrogen cooling wall breaker with a rotation speed of 20,000rpm, add liquid nitrogen with a mass ratio of 10% of the mixed powder, mix and refine for 2 hours, and obtain a mixture with a partic...

Embodiment 3

[0056] A composite bond grinding wheel for large-size silicon carbide substrate processing, mainly used for processing large-size silicon carbide substrate materials, the grinding wheel is composed of a base body and a grinding layer, and the raw materials of the grinding layer are calculated by weight percentage. For: particle size 270 / 325, TTI75.8 diamond abrasive 30%, mixed powder 40%, polyphenylene sulfide 10%, zinc oxide whisker 8%, SG abrasive 12%.

[0057] The mixed powder is obtained through the following process: in terms of mass percentage, 65% of zinc powder, 18% of copper powder, 2% of aluminum powder, and 6% of iron powder are used to vibrate at 2000 times / min for 15min by using a high-frequency vibrating sieve, and then Add 9% graphite, then put the mixture into a liquid nitrogen cooling wall breaker with a rotation speed of 30,000rpm, add liquid nitrogen with a mass ratio of 10% of the mixed powder, mix and refine for 5 hours, and obtain a mixture with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com