Polylactic acid composition containing phosphate nucleating agent and preparation method thereof

A technology of nucleating agent and phosphate, applied in the field of polylactic acid composition containing phosphate nucleating agent and its preparation, can solve the problems of poor heat resistance of polylactic acid, difficult to meet the application, slow crystallization rate, etc., and achieve improved performance , the effect of reducing the interface free energy and improving the crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

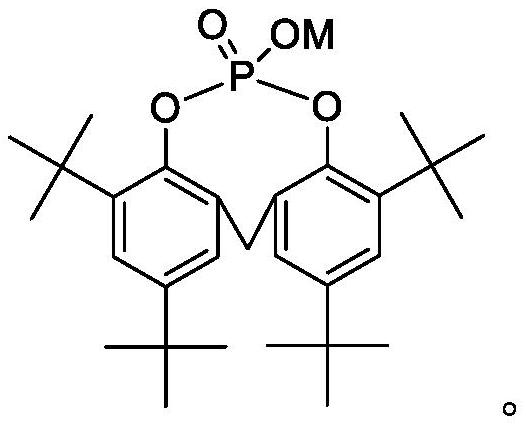

[0027] A phosphate nucleating agent prepared by the following steps:

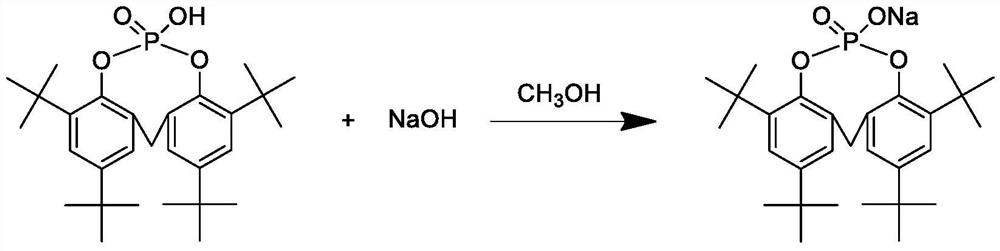

[0028] Step A1: First, fill the reactor with nitrogen to discharge the air, and under the protection of nitrogen atmosphere, add 1mol of 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate and 220g of methanol in sequence into the reactor, after 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate is completely dissolved in methanol, then add 1.2mol sodium hydroxide to the reactor, and use hydrochloric acid Adjusting the pH value of the reaction system to 8, incubating and reacting at 20°C for 2 hours to obtain a crude product;

[0029] The reaction process is as follows:

[0030]

[0031] Step A2: Suction filter the obtained crude product, rinse it twice with deionized water, dry it in vacuum, use denatured alcohol for recrystallization purification, filter and dry it, and prepare the phosphate nucleating agent.

Embodiment 2

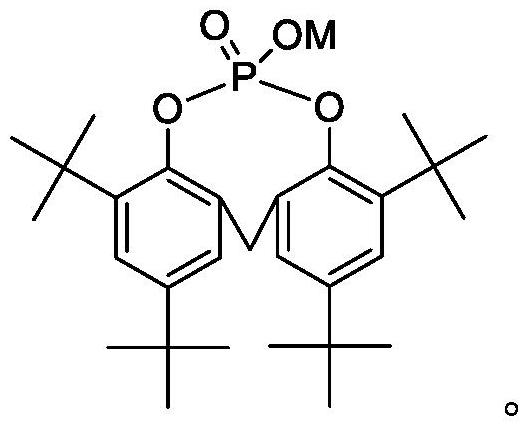

[0033] Step A1: firstly fill the reactor with nitrogen to discharge the air, under the protection of nitrogen atmosphere, add 1mol of 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate and 450g of methanol in sequence Into the reactor, after 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate is completely dissolved in methanol, add 1.3mol barium chloride to the reactor to control the reaction system The pH value of the product was 8, and the reaction was incubated at 30°C for 2 hours to obtain a crude product;

[0034] The reaction process is as follows:

[0035]

[0036] Step A2: Suction filter the obtained crude product, rinse it with deionized water for 3 times, dry it in vacuum, use denatured alcohol for recrystallization and purification, filter and dry it, and prepare the phosphate nucleating agent.

Embodiment 3

[0038] Step A1: First, fill the reactor with nitrogen to discharge the air, and under the protection of nitrogen atmosphere, add 1mol of 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate and 460g of methanol in sequence into the reactor, after 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate is completely dissolved in methanol, then add 1.4mol calcium hydroxide to the reactor, and use hydrochloric acid Adjust the pH value of the reaction system to 8, and keep the reaction at 40°C for 2 hours to obtain the crude product;

[0039] The reaction process is as follows:

[0040]

[0041] Step A2: Suction filter the obtained crude product, rinse it with deionized water for 3 times, dry it in vacuum, use denatured alcohol for recrystallization and purification, filter and dry it, and prepare the phosphate nucleating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com