Composition containing pyridalyl and chlorfenapyr

A technology of triflufenacil and chlorfenapyr, which is applied in the directions of insecticides, animal repellents, plant growth regulators, etc., can solve the problems of easy resistance, short reproduction cycle of pests, and difficult effects, etc. Achieving good synergistic effect and good insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

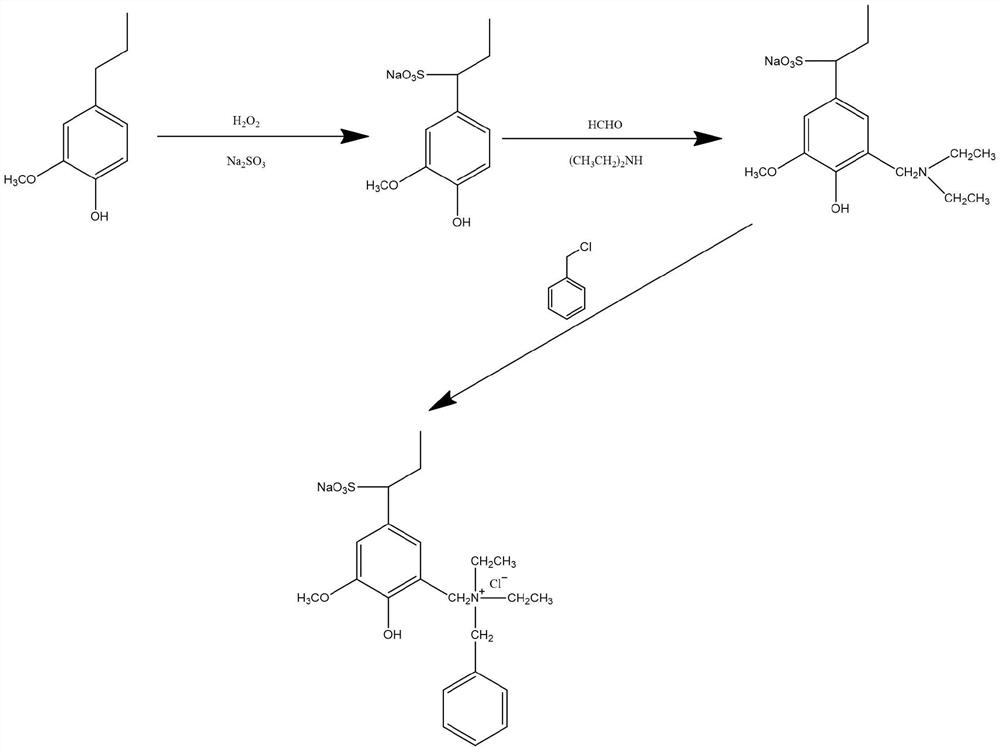

Image

Examples

Embodiment 1

[0032] This embodiment is a preparation method of modified lignin, comprising the following steps:

[0033] S1: Add 10 g of alkali lignin to 150 g of sodium hydroxide solution with a mass fraction of 10%, stir at a stirring rate of 200r / min until the alkali lignin is completely dissolved, filter, and filter the filtrate with a mass fraction of 5% The sulfuric acid solution was adjusted until the pH was 6, centrifuged, and the precipitate was washed with distilled water to neutrality, then placed in a vacuum drying oven, and dried at a temperature of 50°C for 45 hours to obtain refined lignin;

[0034] S2: Add 4g of refined lignin, 100mL of acetic anhydride, pyridine and dioxane at a volume ratio of 1:1:1 into a flask equipped with a stirrer, at a temperature of 50°C and a stirring rate of 200r / Stir and disperse for 1 h under the condition of 1 min, then stop stirring and let stand at constant temperature for 20 h, then cool to room temperature, centrifuge, then add to 300 mL ...

Embodiment 2

[0037] This embodiment is a preparation method of modified lignin, comprising the following steps:

[0038] S1: Add 10g of alkali lignin to 100g of sodium hydroxide solution with a mass fraction of 10%, stir at a stirring rate of 300r / min until the alkali lignin is completely dissolved, and filter the filtrate with a mass fraction of 10%. The sulfuric acid solution was adjusted until the pH was 7, centrifuged, and the precipitate was washed with distilled water to neutrality, then placed in a vacuum drying oven, and dried at a temperature of 55°C for 50 hours to obtain refined lignin;

[0039] S2: Add 4g of refined lignin, 100mL of acetic anhydride, pyridine and dioxane at a volume ratio of 1:1:1 into a flask equipped with a stirrer, at a temperature of 55°C and a stirring rate of 300r / min under the condition of stirring and dispersing for 2h, then stop stirring and let it stand at constant temperature for 30h, then cool to room temperature, centrifuge, then add to 300mL anhy...

Embodiment 3

[0042] This embodiment is a preparation method of a composition containing fluomepyr and chlorfenapyr, comprising the following steps:

[0043] Step 1: dissolving 20g of modified lignin in 200mL of deionized water to obtain an outsourcing solution;

[0044] Step 2: dissolving 1 g of fluomepyr and 19 g of chlorfenapyr in 50 mL of acetone to obtain the inner core solution;

[0045] Step 3: Add the outsourcing liquid and the inner core liquid into a high-speed shearing machine, shear for 5 minutes at a stirring rate of 6000 r / min, add isopropanol, and then stir for 6 hours at a stirring rate of 300 r / min. Afterwards, the composition containing triflumepyr and chlorfenapyr is obtained through evaporation concentration, kneading, extrusion granulation, drying and sieving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com