Method for changing weight, hardness and internal and external color transparent consistency of soft wood

A wood and weight technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of only changing wood hardness and weight, changing wood weight, hardness, internal and external color permeability, etc., to achieve beautiful color and physical mechanics Improved performance and good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

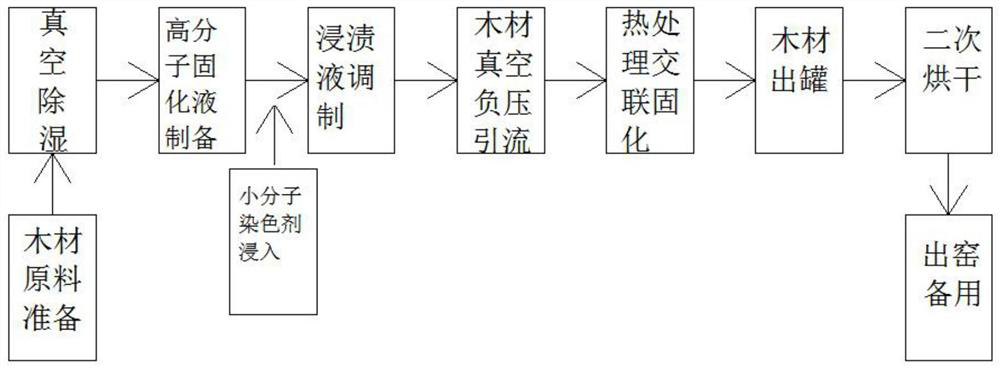

[0034] A method for changing the weight, hardness, and transparent consistency of soft wood, which includes the following steps,

[0035] S1, vacuum dehumidification: put the wet wood after sawing the log into the vacuum dehumidifier, vacuum dehumidify the moisture content of the wood to 8-15%, and set it aside;

[0036] S2, preparation of polymer solidification solution;

[0037] S3, small-molecule dye immersion; select a suitable small-molecule dye, and add the small-molecule dye during the preparation of the polymer solidification solution;

[0038] S3, preparation of impregnating solution: a. Put 1.8-2.5 parts of water in the mass-number ratio into the agitator, and raise the temperature to 30-50°C; b. Add 1 part in mass-number ratio of small molecule dye Polymer solidification solution, heat the mixed solution to 40-60°C, stir until uniform to make a medicinal solution;

[0039] S4, wood vacuum negative pressure catheter drainage: put the sawn timber with a moisture con...

Embodiment 1-1

[0045] The preparation step of polymer solidified liquid comprises: a. The production raw material preparation of polymer solidified liquid: described polymer solidified liquid is made up of the raw material of following mass fraction ratio: polyoxymethylene (POM) 300 parts, 900 parts of urea, carboxymethyl fiber 0.3 parts of plain sodium, 80 parts of ammonia water, 105 parts of melamine, 95 parts of polyvinyl alcohol, 0.9 parts of hexamethylenetetramine and 0.5 parts of diethylene glycol, 300 parts of small molecule color-changing agent;

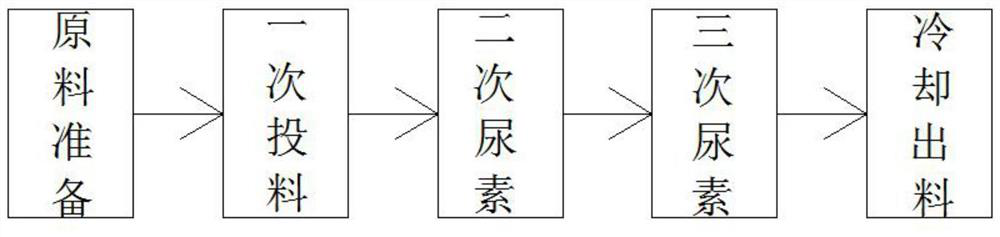

[0046]b. One-time feeding: Add formaldehyde, polyvinyl alcohol, ammonia water, hexamethylenetetramine, melamine, and sodium carboxymethylcellulose to the reaction kettle according to the ratio of the above parts, and first add three-thirds of the total amount of urea. One part of urea, after stirring well, adjust the pH value to 8.5-9.0 with sodium hydroxide;

[0047] c. Secondary urea: heat up to 80-85°C, keep for 10-30 minutes, then add 1...

Embodiment 1-2

[0056] The preparation step of macromolecule solidified liquid comprises: a. the production raw material preparation of macromolecule solidified liquid: described macromolecule solidified liquid is made up of the raw material of following mass fraction ratio: polyoxymethylene (POM) 350 parts, urea 1050 parts, carboxymethyl fiber 0.6 parts of plain sodium, 95 parts of ammonia water, 125 parts of melamine, 115 parts of polyvinyl alcohol, 1.2 parts of hexamethylenetetramine, 00.9 parts of diethylene glycol, and 350 parts of small molecule color-changing agent;

[0057] b. One-time feeding: Add formaldehyde, polyvinyl alcohol, ammonia water, hexamethylenetetramine, melamine, and sodium carboxymethylcellulose to the reaction kettle according to the ratio of the above parts, and first add three-thirds of the total amount of urea. One part of urea, after stirring well, adjust the pH value to 8.5-9.0 with sodium hydroxide;

[0058] c. Secondary urea: heat up to 80-85°C, keep for 10-30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com