Resourceful treatment system and method for efficient reuse of salt-containing mine water

A treatment method, mine water technology, applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of low reuse rate of mine water resources, reduce acid and alkali outsourcing costs, and reduce operation Pressure, the effect of reducing the probability of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

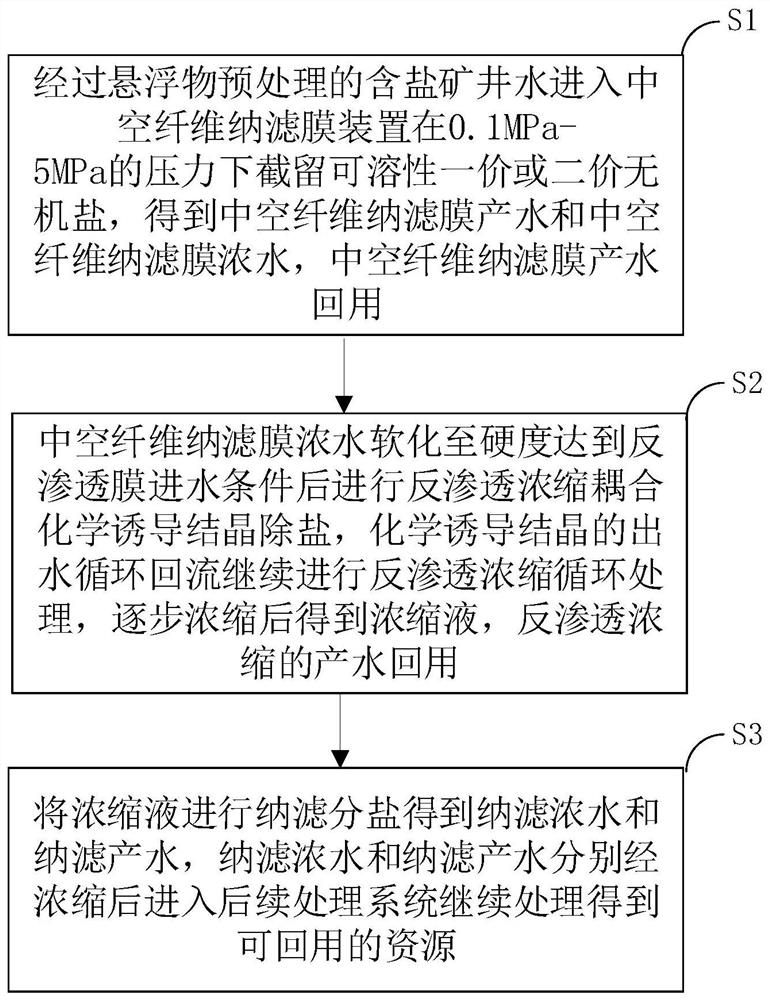

[0058] Such as figure 1 As shown, a resource treatment method for efficient reuse of saline mine water includes the following steps:

[0059] S1. Hollow fiber nanofiltration membrane desalination: the salt-containing mine water pretreated by suspended matter enters the hollow fiber nanofiltration membrane device 1 to intercept soluble monovalent or divalent inorganic salts under a pressure of 0.1MPa-5MPa to obtain hollow fiber nanofiltration membranes. Membrane produced water and hollow fiber nanofiltration membrane concentrated water, hollow fiber nanofiltration membrane produced water for reuse;

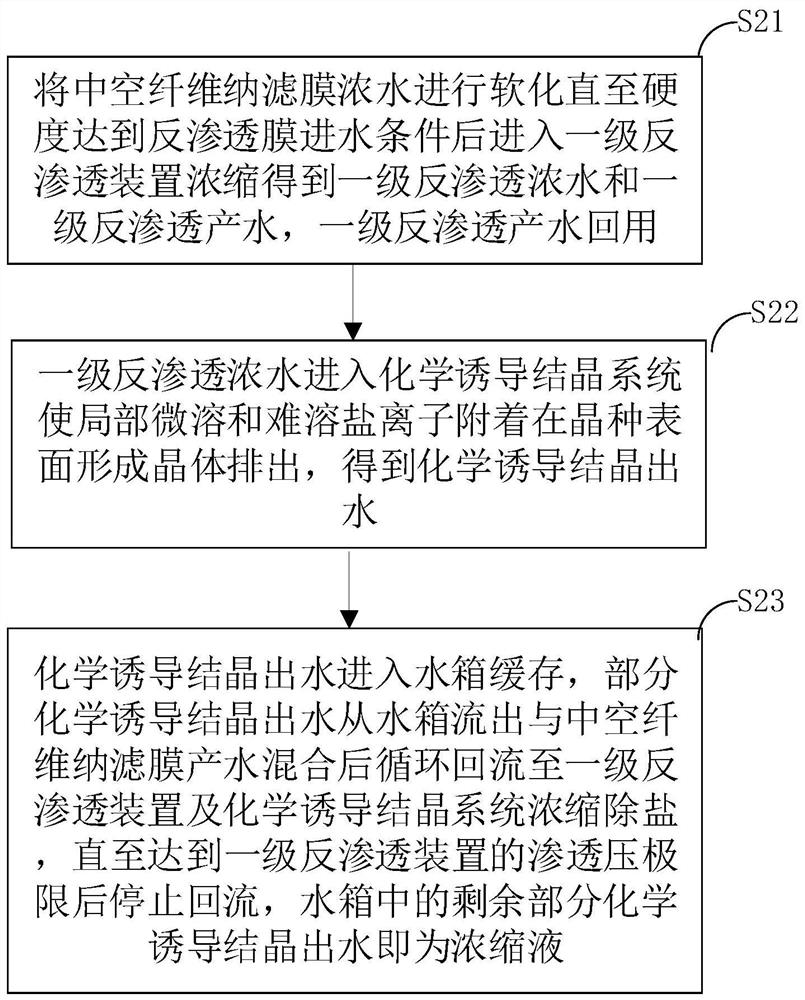

[0060] S2. Concentration: The concentrated water of the hollow fiber nanofiltration membrane is softened until the hardness reaches the water inlet conditions of the reverse osmosis membrane, and then reverse osmosis concentration is coupled with chemically induced crystallization to remove salt. Finally, the concentrated solution is obtained, and the product water concentrated b...

Embodiment 2

[0063] Such as figure 1 As shown, a resource treatment method for efficient reuse of saline mine water includes the following steps:

[0064] S1. Hollow fiber nanofiltration membrane desalination: the salt-containing mine water pretreated by suspended matter enters the hollow fiber nanofiltration membrane device 1 to intercept soluble monovalent or divalent inorganic salts under a pressure of 0.1MPa-5MPa to obtain hollow fiber nanofiltration membranes. Membrane water production and hollow fiber nanofiltration membrane concentrated water, hollow fiber nanofiltration membrane water production reuse, soluble monovalent or divalent inorganic salts mainly include MgSO 4 、Na 2 SO 4 , MgCl 2 and NaCl;

[0065] S2. Concentration: The concentrated water of the hollow fiber nanofiltration membrane is softened until the hardness reaches the water inlet conditions of the reverse osmosis membrane, and then reverse osmosis concentration is coupled with chemically induced crystallizatio...

Embodiment 3

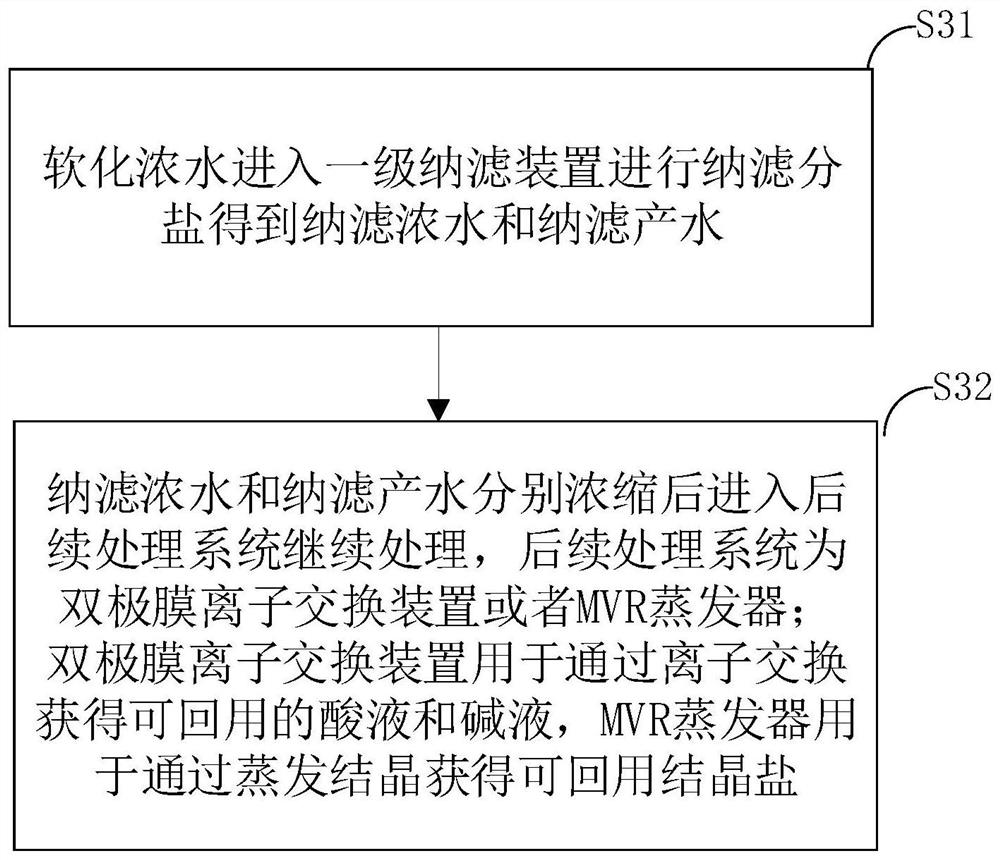

[0074] Such as Figure 4 As shown, a resource treatment method for efficient reuse of saline mine water includes the following steps:

[0075] S1. Pretreatment: The salt-containing mine water is treated to remove suspended matter to obtain pretreated mine water, and the removal of suspended matter is treated as flocculation sedimentation or flocculation sedimentation + ultrafiltration;

[0076] S2. Hollow fiber nanofiltration membrane desalination: Pretreated mine water enters hollow fiber nanofiltration membrane device 1 to intercept soluble monovalent or divalent inorganic salts under a pressure of 0.1MPa-5MPa to obtain hollow fiber nanofiltration membrane produced water and hollow Fiber nanofiltration membrane concentrated water, hollow fiber nanofiltration membrane produced water for reuse;

[0077] S3. Concentration: The concentrated water of the hollow fiber nanofiltration membrane is softened until the hardness reaches the water inlet conditions of the reverse osmosis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com