Roasting reaction generator and nano aluminum oxide production method

A generator and reaction technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of bulk discharge, low thermal efficiency, poor alumina reaction activity, etc., to achieve good corporate and social benefits, There is no pollutant emission and the effect of strong market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

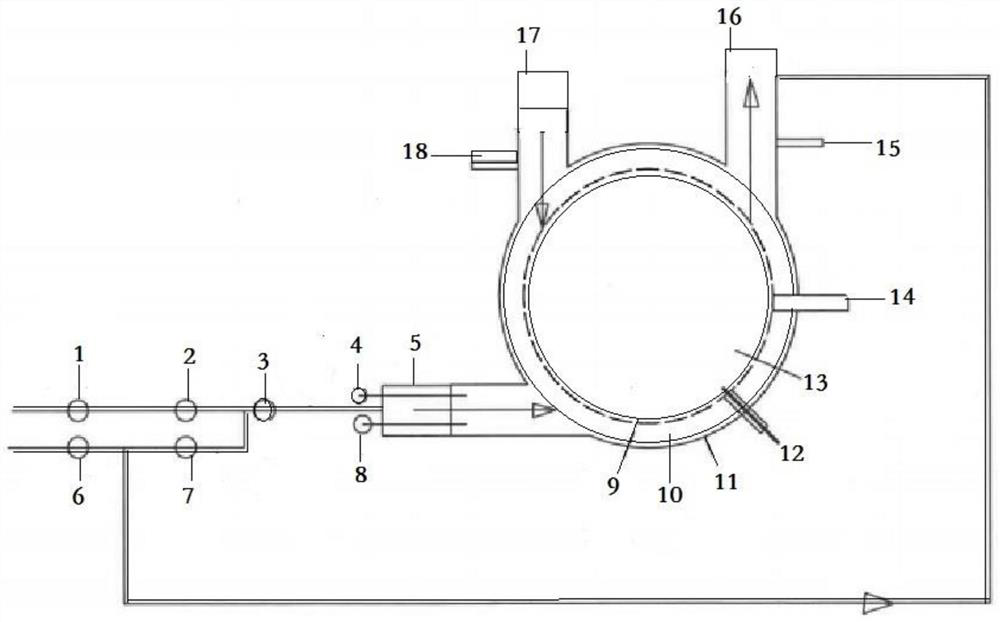

[0014] The premixed natural gas spray gun 5 is equipped with a spray gun solenoid valve 2 for safety protection; the power supply (1, 2 points) of the spray gun solenoid valve 2 is connected to the corresponding insurance and the common zero line, and the valve position signal of the spray gun solenoid valve 2 (3, 4 ) point is connected with the temperature controller (3, 4); the oxygen smart turbine flowmeter 7 is connected with the natural gas smart turbine flowmeter 1; the high-pressure suction blower frequency converter is connected with the RS-232 interface of PLC; The chamber 13 is a spherical structure, the inner layer of the chamber is made of zirconium corundum refractory material 9, the outer layer is wrapped with alumina fiber cotton 10, and the outermost layer is a metal shell 11; the electric actuator 3 for controlling the flow of mixed gas is installed on the solenoid valve of the spray gun 2 and the premixed natural gas spray gun 5; the pressure transmitter 15 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com