Medium-expansion optical fiber image transmission element and preparation method thereof

A technology of optical fiber image transmission and components, applied in the field of optoelectronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

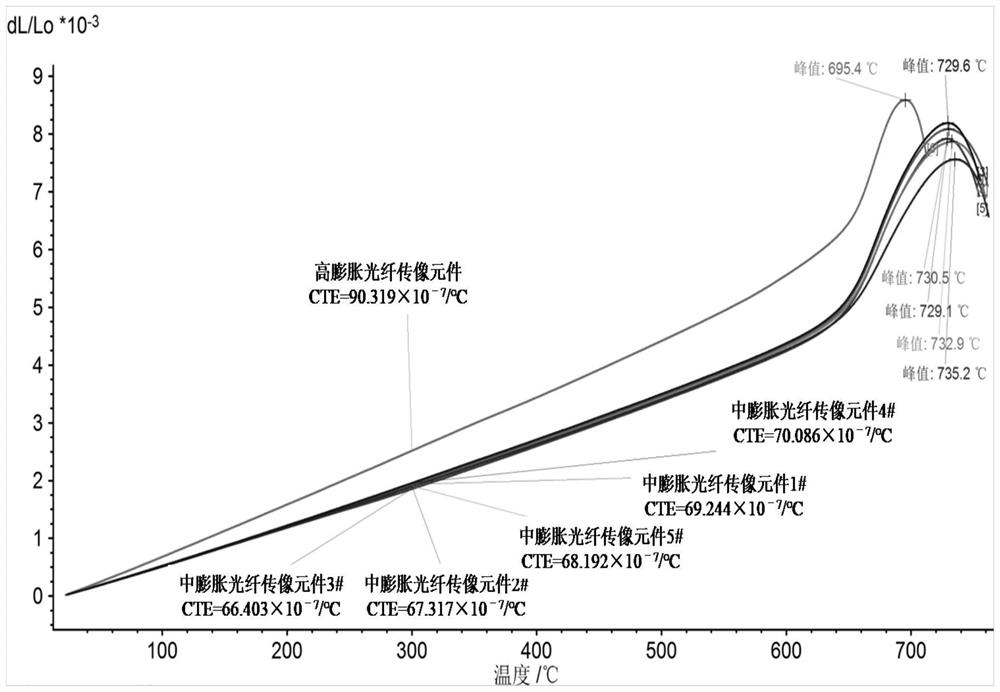

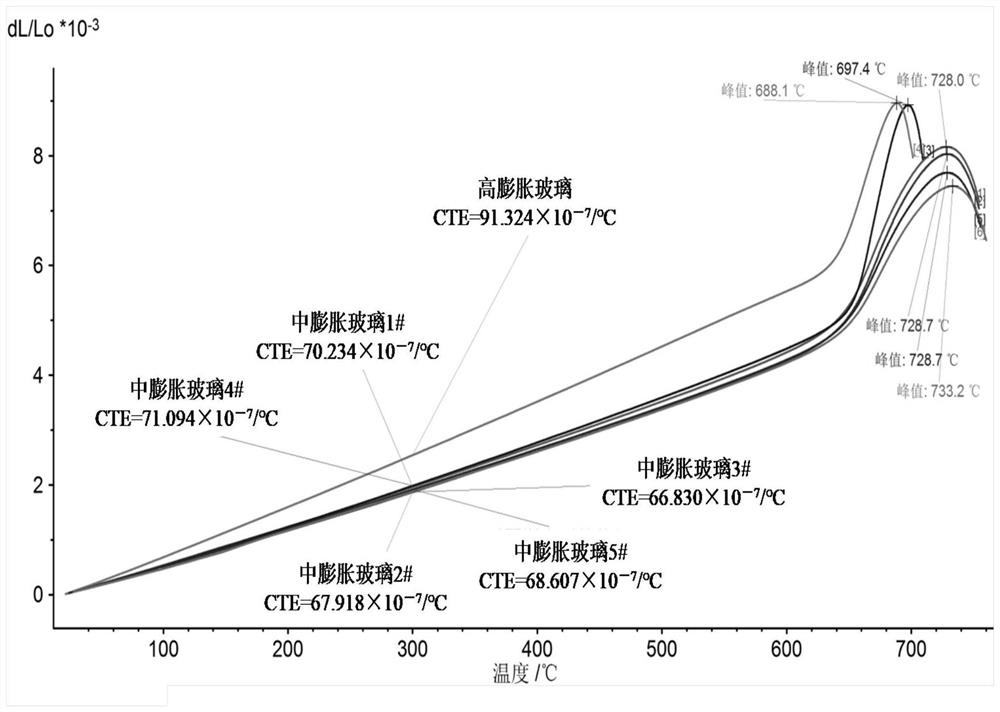

[0071] Preparation of medium expansion core glass:

[0072] Select raw material by table 1 embodiment 1 glass composition, and require the oxide compound such as Fe of variable valence element in the glass raw material 2 o 3 etc. are strictly controlled, and the finished glass Fe 2 o 3 The content is less than 100PPm, and the ingredients meet the glass chemical composition in Table 1, and then quartz sand, aluminum hydroxide, boric acid, calcium carbonate, barium carbonate, lanthanum oxide, niobium oxide, tantalum oxide, yttrium oxide, zinc oxide, titanium dioxide, Put zirconia and tin oxide into a platinum crucible and melt at 1400°C for 6 hours. During the glass melting process, stir the glass twice to make the glass melt evenly. After the glass is melted, lower the temperature to 1320°C. Clarify at ℃ for 2 hours, then cast the molten glass into the specified test product requirements, and then anneal, the annealing process is 625 ℃ for 1 hour, then cool down to 60 ℃ in 1...

Embodiment 2

[0081] Preparation of medium expansion core glass:

[0082] The actual composition of the glass refers to Example 2 of Table 1. Using the same raw material requirements as in Example 1, quartz sand, aluminum hydroxide, boric anhydride, calcium carbonate, barium nitrate, lanthanum oxide, niobium oxide, tantalum oxide, yttrium oxide, zinc oxide , titanium dioxide, zirconia and tin oxide were put into a platinum crucible and melted at 1350°C for 8 hours. During the glass melting process, the glass was stirred once to make the glass melt evenly. Cool down to 1300°C for 1 hour, then cast the molten glass into the specified test product requirements, and then anneal. The annealing process is 600°C for 1 hour, then cool down to 60°C for 12 hours, and then cool with the furnace to room temperature. Using the same test conditions as in Example 1, Table 1 shows the basic properties of the samples. (1) The refractive index is 1.82; (2) The average coefficient of linear expansion at 30-...

Embodiment 3

[0091] Preparation of medium expansion core glass:

[0092] Refer to Example 3 in Table 1 for the actual composition of the glass, use the same raw materials and raw material requirements as in Example 1, melt at a temperature of 1450 ° C for 4 hours, and stir the glass twice during the glass melting process to make the glass melt Evenly, after the glass is melted, it is cooled to 1340°C for 2 hours to clarify, and then the molten glass is cast into the specified test product requirements, and then annealed. The annealing process is 650°C for 1 hour, and then cooled to 60°C, and then cooled to room temperature with the furnace. Using the same test conditions as in Example 1, Table 1 shows the basic properties of the samples. (1) The refractive index is 1.82; (2) The average coefficient of linear expansion at 30-300°C is 66.830×10 -7 / °C.

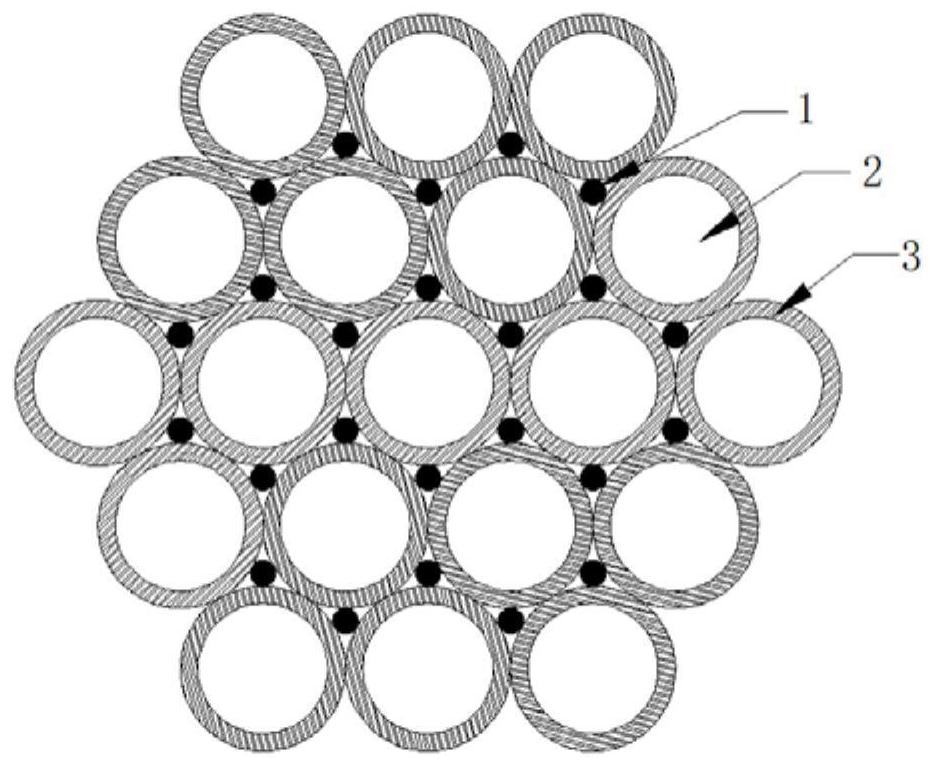

[0093] The original expansion optical fiber image transmission in the preparation:

[0094] (1) Monofilament drawing: Finely grind and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com