A kind of positive electrode material and its preparation method and application

A cathode material, time technology, applied in the direction of positive electrodes, chemical instruments and methods, battery electrodes, etc., can solve the problems of impedance increase, discharge specific capacity decline, research and design ideas, etc., to achieve the effect of increasing energy density and improving high-temperature storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a positive electrode material, the general chemical formula of the positive electrode material is LiCo 0.970 al 0.025 Ni 0.002 mn 0.002 Y 0.001 o 2 .

[0047] The preparation method of the positive electrode material is as follows:

[0048] (1) Cobalt sulfate, aluminum sulfate, nickel sulfate, manganese sulfate, precipitating agent sodium hydroxide, complexing agent ammonium bicarbonate according to the stoichiometric ratio of cobalt, aluminum, nickel, manganese molar ratio of 970:25:2:2 Mix and prepare the solution, obtain cobalt aluminum nickel manganese carbonate after co-precipitation, and then sinter at 800°C for 6 hours to obtain tricobalt aluminum nickel manganese tetraoxide;

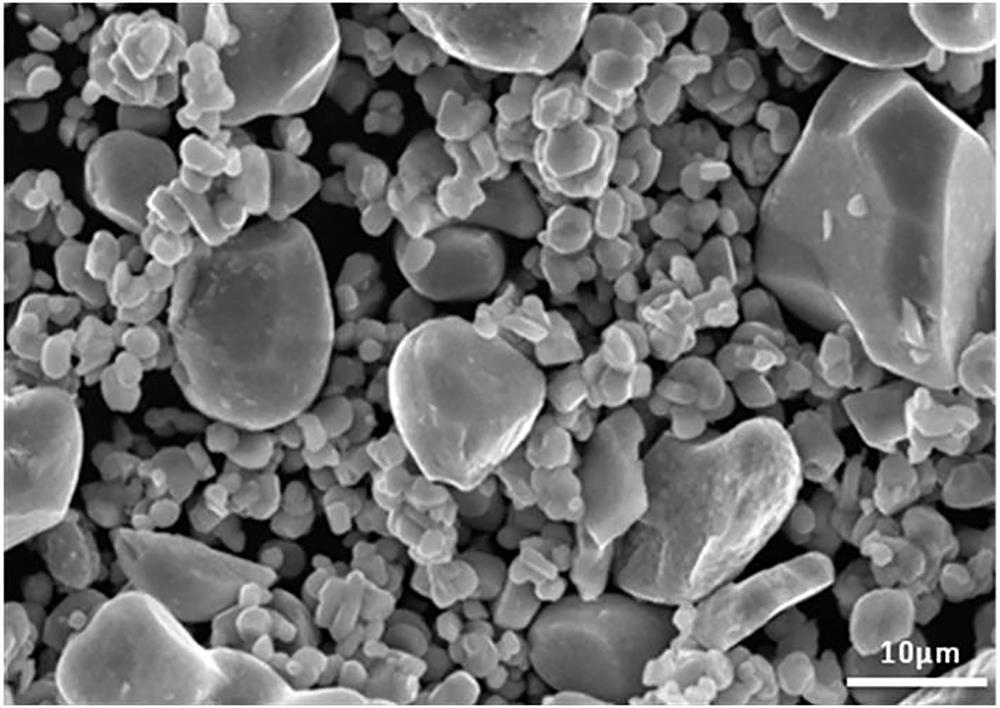

[0049] (2) Weigh and mix cobalt-cobalt-aluminum-nickel-manganese and lithium carbonate at a Li / Co molar ratio of 1.05:1, sinter at 1020°C for 10 hours, then pulverize, wash with water, and dry to obtain median particle sizes of 16 μm and 5 μm, respectively. ...

Embodiment 2

[0053] This embodiment provides a positive electrode material, the general chemical formula of the positive electrode material is LiCo 0.961 al 0.030 Ni 0.004 mn 0.004 Ti 0.001 o 2 .

[0054] The preparation method of the positive electrode material is as follows:

[0055] (1) Cobalt sulfate, aluminum sulfate, nickel sulfate, manganese sulfate, precipitating agent sodium hydroxide, complexing agent ammonium bicarbonate according to the stoichiometric ratio of cobalt, aluminum, nickel, manganese molar ratio of 961:30:4:4 Mix and prepare the solution, obtain cobalt aluminum nickel manganese carbonate after co-precipitation, and then sinter at 850°C for 4 hours to obtain tricobalt aluminum nickel manganese tetraoxide;

[0056](2) Weigh and mix cobalt-cobalt-aluminum-nickel-manganese and lithium carbonate at a Li / Co molar ratio of 1.06:1, sinter at 1080°C for 8 hours, then pulverize, wash with water, and dry to obtain median particle sizes of 18 μm and 4 μm, respectively. T...

Embodiment 3

[0059] This embodiment provides a positive electrode material, the general chemical formula of the positive electrode material is LiCo 0.965 Al 0.027 Ni 0.002 mn 0.002 Mg 0.004 o 2 .

[0060] The preparation method of the positive electrode material is as follows:

[0061] (1) Cobalt sulfate, aluminum sulfate, nickel sulfate, manganese sulfate, precipitating agent sodium hydroxide, complexing agent ammonium bicarbonate according to the stoichiometric ratio of cobalt, aluminum, nickel, manganese molar ratio of 965:27:2:2 Mix and prepare the solution, obtain cobalt aluminum nickel manganese carbonate after co-precipitation, and then sinter at 700°C for 8 hours to obtain tricobalt aluminum nickel manganese tetraoxide;

[0062] (2) Mix three cobalt, aluminum, nickel, manganese and lithium carbonate at a Li / Co molar ratio of 1.02:1, sinter at 1080°C for 13 hours, then pulverize, wash with water, and dry to obtain particles with median diameters of 15 μm and 4 μm, respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com