A kind of injectable polyhydroxyalkanoate microsphere and preparation method thereof

A technology of polyhydroxyalkanoate and microspheres, which is applied in the field of biomedicine, can solve problems such as hindering the application of biodegradable material microspheres, affecting product performance stability, and decreasing overall regularity, etc., to achieve excellent absorbability, biological Compatibility will not, the effect of complete form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of injectable polyhydroxyalkanoate microspheres, comprising the following steps:

[0039] a) dissolving the PHA material in an organic solvent to obtain an oil phase;

[0040] b) dissolving hyaluronic acid in water to obtain an aqueous phase;

[0041] c) adding the oil phase to the water phase dropwise under stirring conditions, after the dropwise addition, continue stirring to volatilize the organic solvent, and then perform solid-liquid separation and drying to obtain PHA microspheres;

[0042] The steps a) and b) are not limited in order.

[0043]In the preparation method provided by the present invention, the PHA material is dissolved in an organic solvent to obtain an oil phase, the hyaluronic acid aqueous solution is used as the water phase, the water phase solution is stirred, and the oil phase is slowly added to the water phase, and the organic solvent is continuously stirred. Volatilization, followed by solid-liquid...

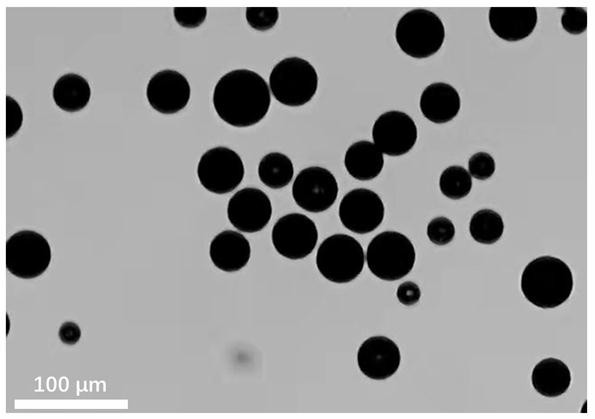

Embodiment 1

[0068]Dissolve 1 g of PHBHHx (molecular weight 20-100 KDa, average molecular weight 50 KDa) in 20 mL of dichloromethane to make an organic solution with a final concentration of 5% (w / v), which is the oil phase. Dissolve hyaluronic acid (molecular weight 5-100 KDa, average molecular weight 50KDa) in distilled water to prepare an aqueous solution with a final concentration of 0.5% (w / v), which is the aqueous phase. A magnetic stirrer was used to stir the water phase at a speed of 400 rpm, and at the same time, the oil phase was slowly added dropwise to the water phase under stirring, and the volume ratio of the two solutions was 1:50. Continue stirring at a speed of 400 rpm with a magnetic stirrer to form an emulsion; continue stirring at this speed for 5 h to remove the organic solvent. Afterwards, the resulting solution was first frozen (-80°C for 6 h), and then freeze-dried (-40°C for 24 h) to remove water to obtain injectable PHBHHx microspheres.

[0069] According to the ...

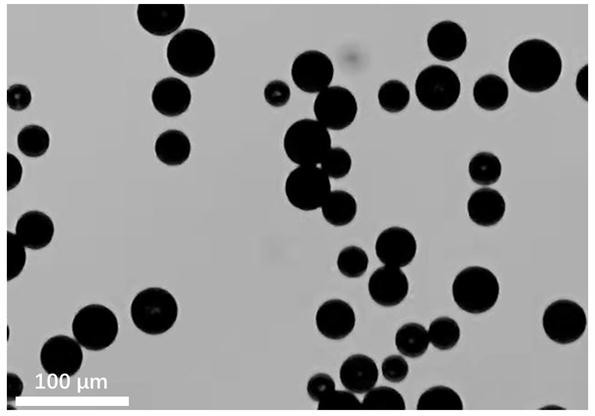

Embodiment 2

[0071] Dissolve 1 g of PHBVHHx (molecular weight 20-100 KDa, average molecular weight 50 KDa) in 20 mL of dichloromethane to make an organic solution with a final concentration of 5% (w / v), which is the oil phase. Dissolve hyaluronic acid (molecular weight 10-200 KDa, average molecular weight 50KDa) in distilled water to prepare an aqueous solution with a final concentration of 0.5% (w / v), which is the aqueous phase. A magnetic stirrer was used to stir the water phase at a speed of 400 rpm, and at the same time, the oil phase was slowly added dropwise to the water phase under stirring, and the volume ratio of the two solutions was 1:50. Continue stirring at a speed of 400 rpm with a magnetic stirrer to form an emulsion; continue stirring at this speed for 4 h to remove the organic solvent. Afterwards, the resulting solution was first frozen (-40°C for 12 h), and then freeze-dried (-40°C for 24 h) to remove water to obtain injectable PHBVHHx microspheres.

[0072] The yield of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com