Polytetrafluoroethylene composite material, and preparation method and application thereof

A technology of polytetrafluoroethylene and polytetrafluoroethylene resin, which is applied in the field of polytetrafluoroethylene composite materials and its preparation, can solve problems such as unsatisfactory use requirements, decreased tensile strength and toughness, high elongation at break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

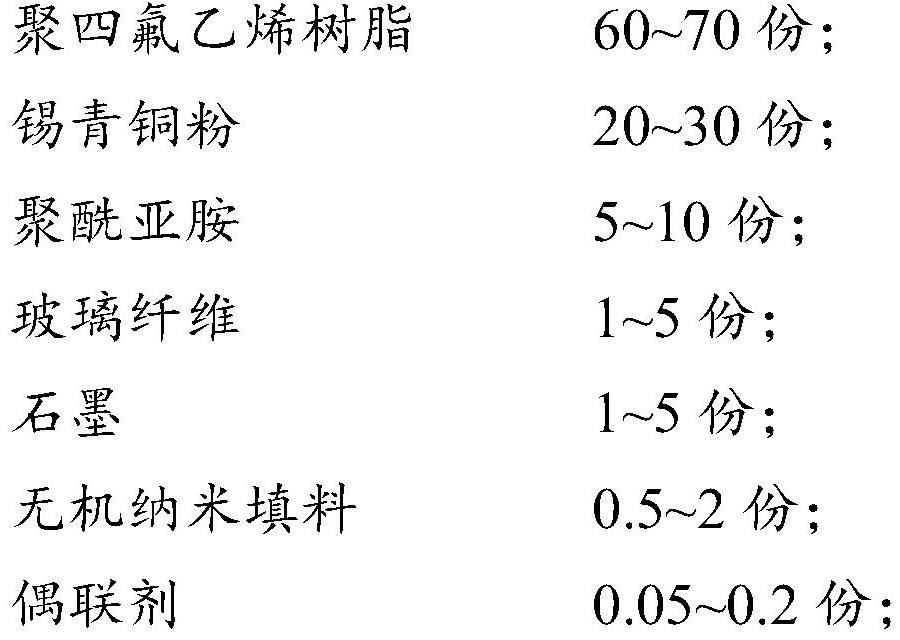

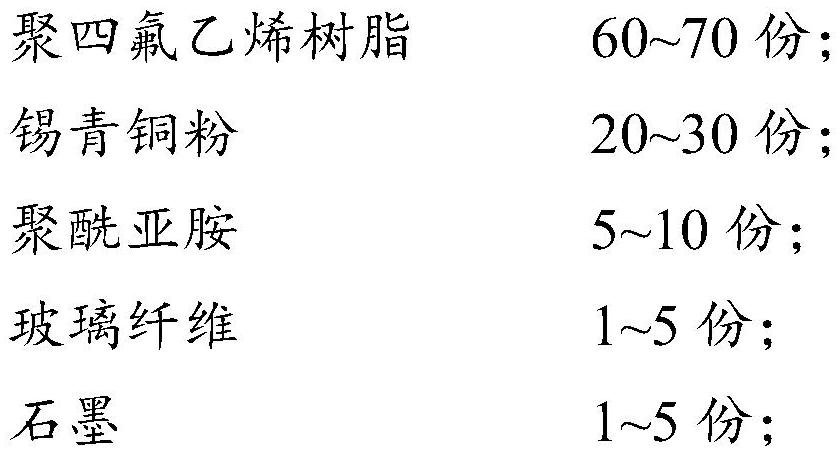

[0042] The present invention also provides a preparation method of the polytetrafluoroethylene composite material described in the above technical solution, comprising the following steps:

[0043] mixing coupling agent, inorganic nano filler, glass fiber, polytetrafluoroethylene resin, polyimide, graphite, tin bronze powder and absolute ethanol to obtain a compound;

[0044] Compressing the mixture to obtain a blank;

[0045] Sintering the blank to obtain the polytetrafluoroethylene composite material;

[0046] The particle diameters of the polytetrafluoroethylene resin, tin bronze powder, polyimide, glass fiber and graphite are in micron order.

[0047] The invention mixes coupling agent, inorganic nano filler, glass fiber, polytetrafluoroethylene resin, polyimide, graphite, tin bronze powder and absolute ethanol to obtain the compound.

[0048] In the present invention, the mixing preferably includes the following steps:

[0049] After the coupling agent and absolute ethan...

Embodiment 1

[0063] Disperse 0.1g of N,-[3-(trimethoxysilyl)propyl]ethylenediamine in 300g of absolute ethanol, stir for 0.5h, add 1g of nano-silicon carbide (particle size is 20nm) and 5g of glass fiber (diameter is 14μm, aspect ratio is 8:1), after stirring for 0.5h, add 70g polytetrafluoroethylene resin (particle size is 50μm), 5g polyimide (particle size is 45μm), 3g graphite (particle size Diameter is 5 μm) and 20g tin bronze powder (brand 663, particle diameter is 2 μm), after stirring for 1h, filter, dry, obtain mixture;

[0064] Put the mixture in a small universal pulverizer, add 300g each time, rotate at 24000rpm, and take 30s. After passing through a 45-mesh sieve, add the sieved mixture into the mould, first using a pressure of 25MPa After forward pressing for 1 min and compaction, adopt a pressure of 50 MPa to press upside down for 5 min, demould, and obtain a blank;

[0065] Put the blank into a sintering furnace for sintering, raise the temperature from room temperature to ...

Embodiment 2

[0067] Disperse 0.06g of N,-[3-(trimethoxysilyl)propyl]ethylenediamine in 200g of absolute ethanol, stir for 1h, add 0.5g of nano silicon carbide (particle size 15nm), 0.5g of nano Silicon nitride (particle size is 30nm) and 3g glass fiber (diameter is 12μm, aspect ratio is 10:1), after stirring for 1h, add 65g polytetrafluoroethylene resin (particle size is 70μm), 10g polyimide Amine (38 μm in particle size), 1 g of graphite (1 μm in particle size) and 25 g of tin bronze powder (grade 663, 1 μm in particle size), stirred for 1 hour, filtered, and dried to obtain a mixture;

[0068] Put the mixture in a small universal pulverizer, add 350g each time, rotate at 24000rpm, and take 40s. After passing through a 70-mesh sieve, add the sieved mixture into the mold, and first use a pressure of 20MPa After forward pressing for 2 minutes and compaction, adopt a pressure of 45 MPa to press upside down for 7 minutes, demoulding, and obtain a blank;

[0069] Put the blank into a sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com