Preparation method of 4, 4'-dinitrobibenzyl

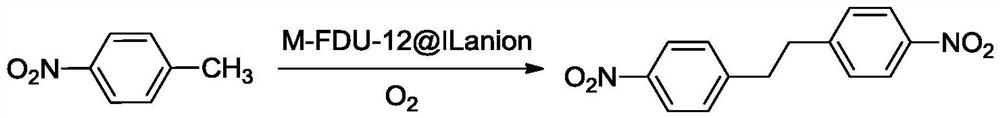

A technology of dinitrobibenzyl and p-nitrotoluene, which is applied in the field of fine chemicals, can solve the problems of poor recycling of waste alkali, high industrialization cost, troublesome reaction operation, etc., and achieve a green and efficient reaction system and a safe and clean oxidant , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

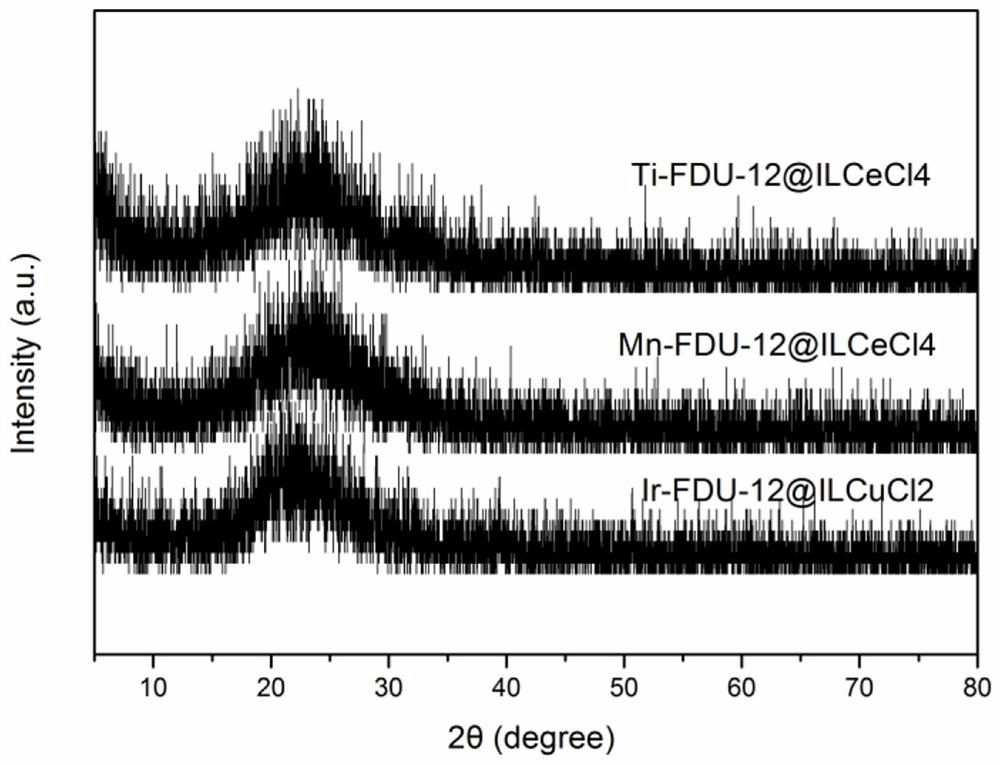

[0038] The preparation method of metal-modified mesoporous material supported guanidinium salt ionic liquid catalyst comprises the following steps:

[0039] (1) Tetrabutylurea (0.5mol) and phosphorus oxychloride (0.6mol) react in toluene (200mL) solvent at 65°C for 24 hours, then add n-hexylamine (1.25mol) and continue the reaction for 22 hours, then add mass Adjust the pH to neutral with a fraction of 20% NaOH aqueous solution, extract the mixture with dichloromethane (400 mL), recover the solvent, and dry to obtain intermediate a;

[0040] (2) Then react intermediate a (0.3mol) with 3-chloropropyltriethoxysilane (0.3mol) in toluene (180mL) at 100°C for 24 hours, recover the solvent and dry to obtain intermediate b;

[0041] (3) intermediate b (0.15mol) in acetonitrile (180mL) solvent and CoCl 2 , CuCl or CeCl 3 (0.2mol) was reacted at 70°C for 24 hours, washed with acetonitrile, and dried to obtain ionic liquid c;

[0042] (4) Ionic liquid c (6 g) was reacted with transit...

Embodiment 2

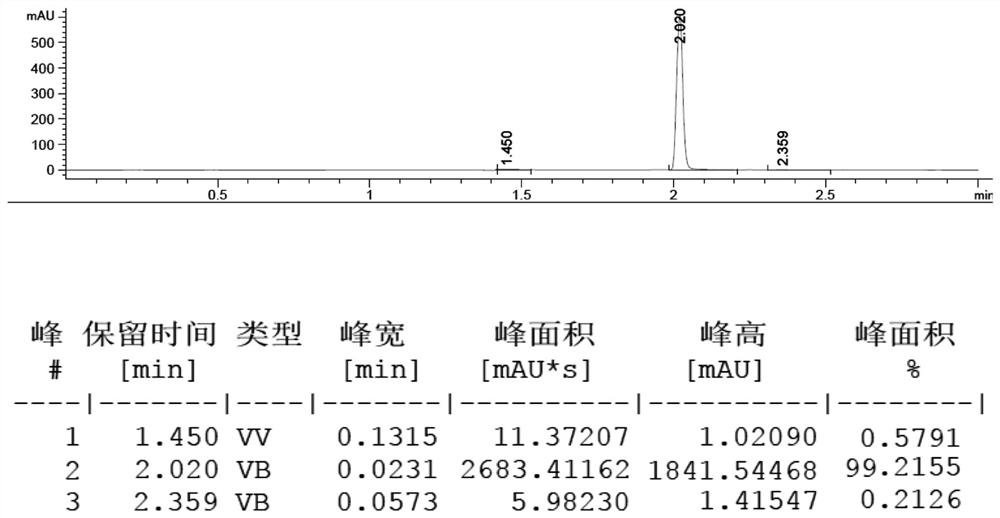

[0046] In the reactor, add p-nitrotoluene (0.1mol), ethanol (100mL), Ir-FDU-12@ILCuCl 2 (0.4g), oxygen was introduced under stirring, and the oxygen flow rate was 3mL / min, and then the stirring reaction was continued at 45°C for 2 hours. The product phase and the catalyst phase can be separated by pouring it while it is hot, and the filtrate is cooled to room temperature, and the product is precipitated from the filtrate, filtered, and dried to obtain the pure product 4,4'-dinitrobibenzyl with a yield of 94%. figure 1 The HPLC analysis results showed that the purity of 4,4'-dinitrobibenzyl was 99.2%.

Embodiment 3

[0048] In the reactor, add p-nitrotoluene (0.1mol), ethanol (100mL), Ir-FDU-12@ILCoCl 3 (0.6g), feed oxygen under stirring, the oxygen flow rate is 5mL / min, then continue to stir and react at 50°C for 3 hours. The product phase and the catalyst phase can be separated by pouring it while it is hot, and the filtrate is cooled to room temperature, and the product is precipitated from the filtrate, filtered, and dried to obtain the pure product 4,4'-dinitrobibenzyl with a yield of 78%. HPLC analysis is the same as in Example 2, only the purity of 4,4'-dinitrobibenzyl is 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com