Perovskite type composite photocatalyst and preparation method thereof, and special system and method

A perovskite-type, photocatalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of low utilization of photogenerated charge carriers, inability to absorb and utilize visible light, Reducing problems such as light utilization efficiency, to achieve the effect of improving photocatalytic performance, improving photocatalytic performance, and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

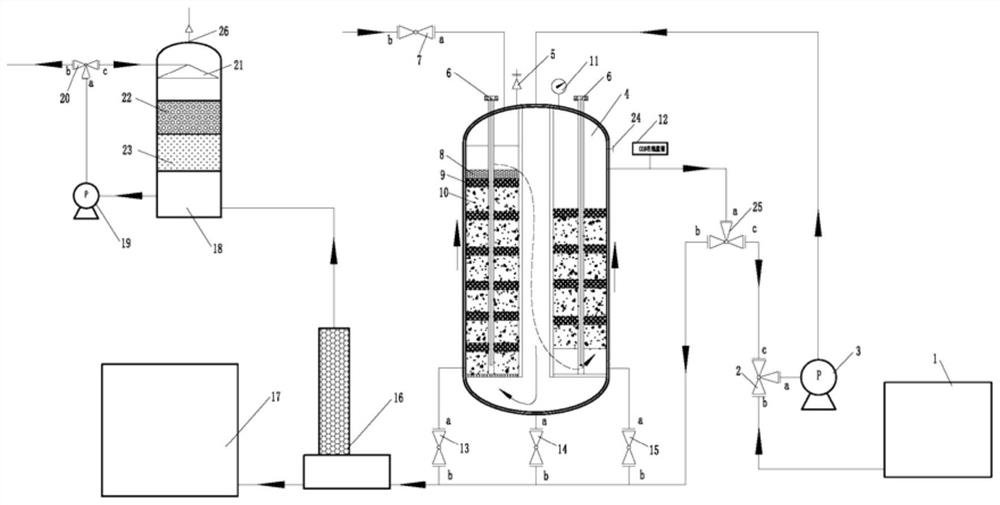

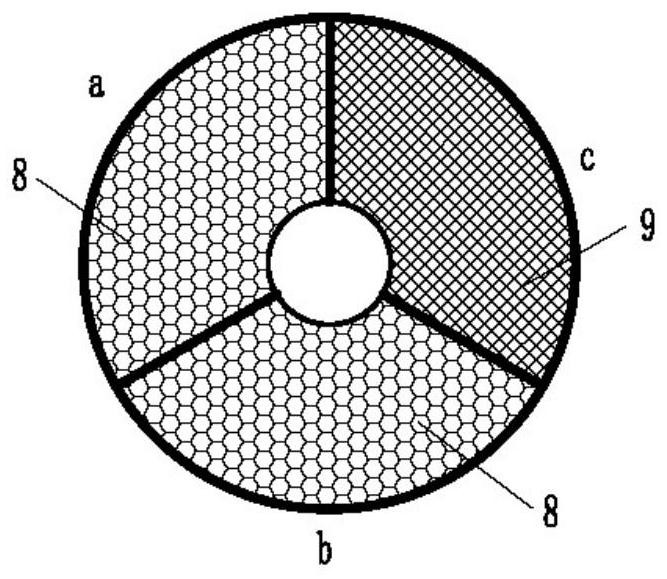

[0040] Such as figure 1 As shown, the special system for photocatalytic wastewater treatment of semiconductor organic wastewater includes a sedimentation module, a photocatalytic wastewater recycling treatment module, an exhaust gas absorption module and a wastewater storage module. The settling module includes a solid settling tank 1 , a three-way liquid inlet regulating valve 2 and a liquid inlet pump 3 . The photocatalytic wastewater circulation treatment module includes a photocatalytic reactor 4 and a COD online monitor 12. The top of the photocatalytic reactor 4 is respectively provided with a safety valve 5, an air intake regulating valve 7, a pressure gauge 11 and a liquid level gauge 24. The photocatalytic reaction The inside of device 4 is divided into a zone, b zone and c zone (such as figure 2 shown), each area is provided with a light source 6 from top to bottom, and each area is provided with alternately arranged fillers 9 and perovskite composite photocatalyst...

Embodiment 2

[0049] (1)LaNi 0.96 co 0.04 o 3 preparation of

[0050]According to cationic and anionic surfactant mol ratio is 1: 10, takes by weighing 3.645g cetyltrimethylammonium bromide and 57.650g fatty alcohol polyoxyethylene ether sodium sulfate, according to water and cationic surfactant mass ratio is 1: 0.024, add 150mL deionized water, stir well to get vesicle solution, according to the molar ratio of lanthanum nitrate hexahydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate is 1:0.96:0.04, add 8.660g lanthanum nitrate hexahydrate, 5.583g Mix and dissolve nickel nitrate hexahydrate and 0.232g cobalt nitrate hexahydrate, add tetramethylammonium hydroxide to adjust pH=12, filter the obtained precipitate, wash with deionized water and absolute ethanol several times, centrifuge, and dry in an oven at 85°C 12h, calcined in a muffle furnace at 800°C for 4h to obtain LaNi 0.96 co 0.04 o 3 .

[0051] (2)LaNi 0.96 co 0.04 o 3 / CeO 2 preparation of

[0052] LaNi sy...

Embodiment 3

[0056] (1)LaNi 0.94 co 0.06 o 3 preparation of

[0057] According to cationic and anionic surfactant mol ratio is 1: 2.5, takes by weighing 3.645g cetyl trimethylammonium bromide and 14.580g fatty alcohol polyoxyethylene ether sodium sulfate, according to water and cationic surfactant mass ratio is 1: 0.03, add 120mL deionized water, stir well to obtain vesicle solution, according to the molar ratio of lanthanum nitrate hexahydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate is 1:0.94:0.06, add 8.660g lanthanum nitrate hexahydrate, 5.467g Nickel nitrate hexahydrate and 0.349g cobalt nitrate hexahydrate were stirred and dissolved, and tetramethylammonium hydroxide was added to adjust the pH to 9. The resulting precipitate was filtered, washed with deionized water and absolute ethanol several times, centrifuged, and dried in an oven at 85°C 12h, calcined in a muffle furnace at 800°C for 4h to obtain LaNi 0.94 co 0.06 o 3 .

[0058] (2)LaNi 0.94 co 0.06 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com