Iron phosphate dihydrate with flexibly adjustable crystal structure and preparation method thereof

A technology of ferric phosphate dihydrate and crystal structure, applied in structural parts, chemical instruments and methods, secondary batteries, etc., can solve the problem of unimproved ionic conductivity, achieve uniform size, improve ion mobility, and rate performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

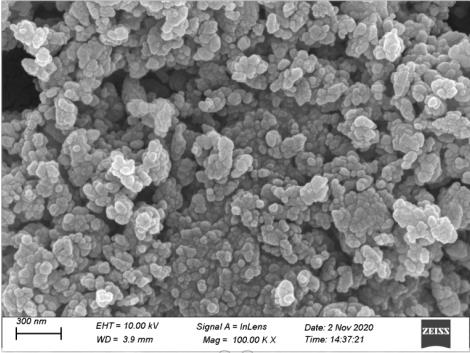

Embodiment 1

[0032] Configure 1.2mol / L ferrous sulfate solution and phosphate solution.

[0033] Weigh the ferrous solution and the phosphate solution according to the molar ratio Fe:P=1:1 for later use, and weigh the excess hydrogen peroxide by 30% for later use.

[0034] Add the weighed phosphate and hydrogen peroxide dropwise to the ferrous solution at the same time, add ammonia water to adjust the pH of the synthetic slurry to 2.2, and react for 1 hour to prepare an amorphous ferric phosphate slurry.

[0035] The amorphous ferric phosphate slurry is pumped into the filter press for filter press rinsing, using pure water with a conductivity lower than 10µs / cm for rinsing, and the conductivity is washed to 5ms / cm to obtain a clean filter cake.

[0036] The filter cake is transported to the paddle tank, and added according to the weight ratio of filter cake and water of 1:5 to obtain a slurry with a solid content of 20%.

[0037] Phosphoric acid and ammonia water are added to the slurry ...

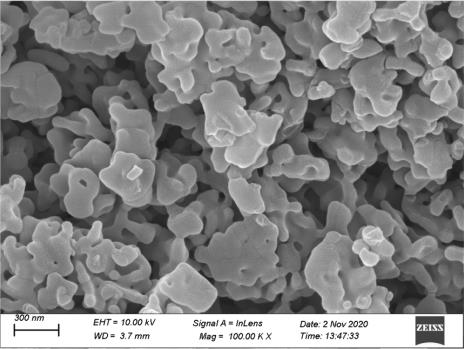

Embodiment 2

[0043] Configure 1.2mol / L ferrous sulfate solution and phosphate solution.

[0044] Weigh the ferrous solution and phosphate solution according to Fe:P=1:1.01 for later use, and weigh 30% excess hydrogen peroxide for later use.

[0045] Add the weighed phosphate and hydrogen peroxide dropwise to the ferrous solution at the same time, add ammonia water to adjust the pH of the synthetic slurry to 3.0, and react for 1 hour to prepare an amorphous ferric phosphate slurry.

[0046] The amorphous ferric phosphate slurry is pumped into the filter press for filter press rinsing, using pure water with a conductivity lower than 10 µs / cm for rinsing, and the conductivity is washed to 5 ms / cm to obtain a clean filter cake.

[0047] Transport the filter cake to the paddle tank, and add it according to the weight ratio of filter cake and water of 1:10 to obtain a slurry with a solid content of 10%;

[0048] Phosphoric acid and ammonia water are added to the slurry to adjust the pH value of...

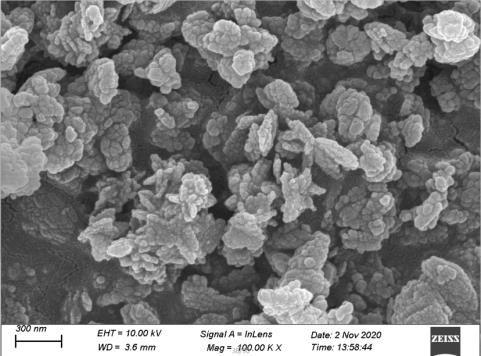

Embodiment 3

[0054] Configure 1.2mol / L ferrous sulfate solution and phosphate solution.

[0055] Weigh the ferrous solution and phosphate solution according to Fe:P=1:1.05 for later use, and weigh 30% excess hydrogen peroxide for later use.

[0056] Add the weighed phosphate and hydrogen peroxide dropwise into the ferrous solution at the same time, add ammonia water to adjust the pH of the synthetic slurry to 3.5, and react for 1 hour to prepare an amorphous ferric phosphate slurry.

[0057] The amorphous ferric phosphate slurry is pumped into the filter press for filter press rinsing, using pure water with a conductivity lower than 10µs / cm for rinsing, and the conductivity is washed to 5ms / cm to obtain a clean filter cake.

[0058] The filter cake is transported to the paddle tank, and added according to the weight ratio of filter cake and water of 1:2.5 to obtain a slurry with a solid content of 30%.

[0059] Phosphoric acid and ammonia water are added to the slurry to adjust the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com