Soil conditioner for peanut planting as well as preparation method and use method of soil conditioner

A soil conditioner and a peanut planting technology, which is applied in the field of soil improvement, can solve the problems of soil compaction, unsuitability for peanut planting, and peanut yield reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

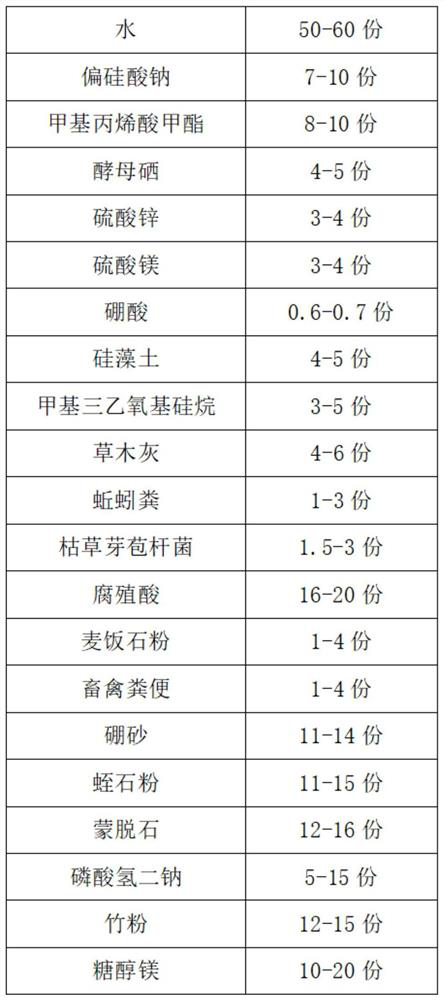

[0022] The invention provides a soil improver for peanut planting, comprising: 50-60 parts of water, 7-10 parts of sodium metasilicate, 8-10 parts of methyl methacrylate, 4 parts of yeast selenium in parts by weight -5 parts, 3-4 parts of zinc sulfate, 3-4 parts of magnesium sulfate, 0.6-0.7 parts of boric acid, 4-5 parts of diatomaceous earth, 3-5 parts of methyltriethoxysilane, 4-6 parts of plant ash, Vermicompost 1-3 parts, Bacillus subtilis 1.5-3 parts, humic acid 16-20 parts, medical stone powder 1-4 parts, livestock manure 1-4 parts, borax 11-14 parts, vermiculite powder 11- 15 parts, 12-16 parts of montmorillonite, 5-15 parts of disodium hydrogen phosphate, 12-15 parts of bamboo powder and 10-20 parts of magnesium sugar alcohol.

[0023] A preparation method for a soil conditioner for peanut planting, comprising the steps of:

[0024] Step 1. Weigh 50 parts of water, 7 parts of sodium metasilicate, 8 parts of methyl methacrylate, 4 parts of yeast selenium, 3 parts of z...

Embodiment 2

[0033] The invention provides a soil improver for peanut planting, comprising: 50-60 parts of water, 7-10 parts of sodium metasilicate, 8-10 parts of methyl methacrylate, 4 parts of yeast selenium in parts by weight -5 parts, 3-4 parts of zinc sulfate, 3-4 parts of magnesium sulfate, 0.6-0.7 parts of boric acid, 4-5 parts of diatomaceous earth, 3-5 parts of methyltriethoxysilane, 4-6 parts of plant ash, Vermicompost 1-3 parts, Bacillus subtilis 1.5-3 parts, humic acid 16-20 parts, medical stone powder 1-4 parts, livestock manure 1-4 parts, borax 11-14 parts, vermiculite powder 11- 15 parts, 12-16 parts of montmorillonite, 5-15 parts of disodium hydrogen phosphate, 12-15 parts of bamboo powder and 10-20 parts of magnesium sugar alcohol.

[0034]A method for preparing a soil conditioner for peanut planting, comprising the following steps: Step 1, weighing 60 parts of water, 10 parts of sodium metasilicate, 10 parts of methyl methacrylate, 5 parts of yeast selenium, and 4 parts o...

experiment example

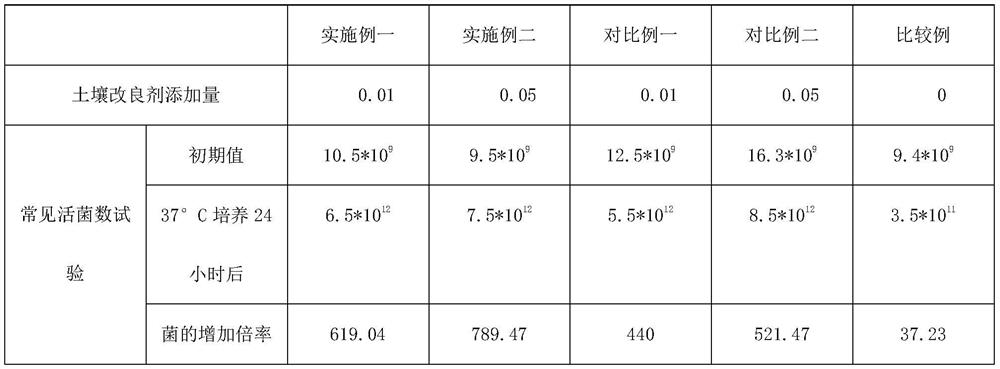

[0043] Experimental object: with reference to the national standard, the soil improver prepared in the embodiment of the present invention is used as the experimental group one, the soil improver obtained in the embodiment two is used as the experiment group two, and the soil improver on the market is selected as the common For comparison group one and better for comparison group two.

[0044] Purpose of the experiment: Under the same conditions, add 0.01g of each to test the number of common viable bacteria before distribution (initial value) and after culturing at 37°C for 24 hours, and the measurement results are shown in the table below.

[0045] Experimental result table:

[0046]

[0047] As can be seen from the above experimental result table, the prepared soil improver of the present invention has good soil improvement performance, which is beneficial to improving the peanut planting soil and improving its yield.

[0048] Working principle: when the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com