Color-changing raincoat

A technology of raincoat and shell powder, which is applied in protective clothing, special outerwear, coats, etc., can solve the problems of easy wear and tear of the covering layer, and the decline of the covering power of the pattern layer on the surface of the raincoat, and achieve fast sensitivity, improve mechanical properties, and durability Good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0028] The preparation method of the shell powder includes the following steps: (1) Wash the 15kg shell with water, when cleaning it in the ultrasonic cleaning machine, removing impurities such as sediment surface of the shell surface; configuration mass fraction is The 2% sodium hydroxide solution such that the shell is completely immersed in a sodium hydroxide solution, soaked 24 h and stirring during the soaking process; (2) filtrate the above-mentioned shell filtrate, then placed in an environment of 110 ° C The high temperature treatment was performed, and the time was 7 h, and then the high temperature treatment after the high temperature treatment was vibrated with the vibrating screening machine, so that the keratin layer of the shell surface was detached; (3) Clean the shell obtained in the above step (2) for cleaning multiple times, Then dry at 60 ° C until the mass is no longer changed, and then the seashell is grinded, then the seashell is grinded and sieved, and the s...

preparation example 2

[0030] The preparation method of silica includes the following steps: (1) mixing 60 kg and 25 kg of ammonia is mixed to give a mixed liquid, and then 30 kg of orthosilicate is added to the above mixed liquid, and stirring is not disconnected, and The reaction was reacted at room temperature (25 ° C) to give a suspension; (2) weighing 3 kg of silane coupling agent (KH-570) and dissolved in anhydrous ethanol of 10 kg, then the resulting solution was added to the above steps. 1) The suspension obtained in the obtained, and the reaction was reacted at room temperature (25 ° C) for 48 hours, then centrifugal filtration was carried out, and a deionized water was cleaned, and finally dried at 60 ° C to obtain the desired Silica.

Embodiment 1

[0032] S1, the preparation of the cover layer ink, 40 kg of epoxy-acrylic resin, 12 kg aqueous polyurethane emulsion, 9 kg diluent (mass ratio of distilled water and ethylene glycol is 1: 1), then add 9 kg of silica in order 10kg seashell powder, 1kg polyethylene wax, 2kg emulsion silicone oil, 1 kg leveling agent (fluorine modified polyacrylate leveling agent), stir mixing is uniformly obtained to print ink raw materials on the raincoat body.

[0033] The preparation of S2, colorless raincoat is printed on the surface of the raincoat body, thereby forming a patterned layer on the surface of the raincoat body, and then printing the ink of step S1 in the rainccoat layer, covering the ink body, covering The layer can cover the pattern layer and then dried with hot air at 60 ° C for 2 min. The thickness ratio of the cover layer and the pattern layer is about 1: 1.

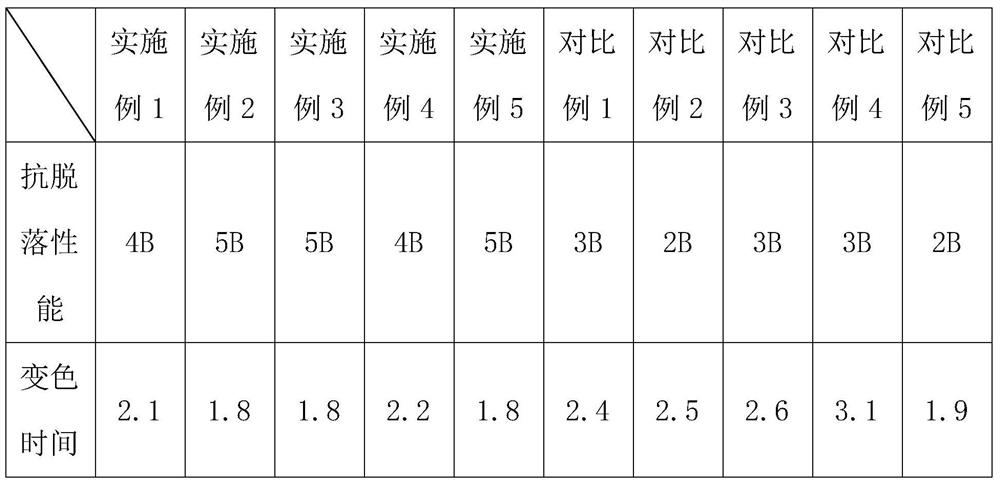

[0034] The preparation process of other embodiments and the preparation processes of Example 1 were all identical, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com