Lithium ion battery cell with sandwich structure, electric pile, and preparation methods thereof

A lithium-ion battery, sandwich technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as the inability of the diaphragm to transmit lithium ions independently, leakage of organic liquid electrolytes, safety hazards, etc., to solve cooling problems and improve contact. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

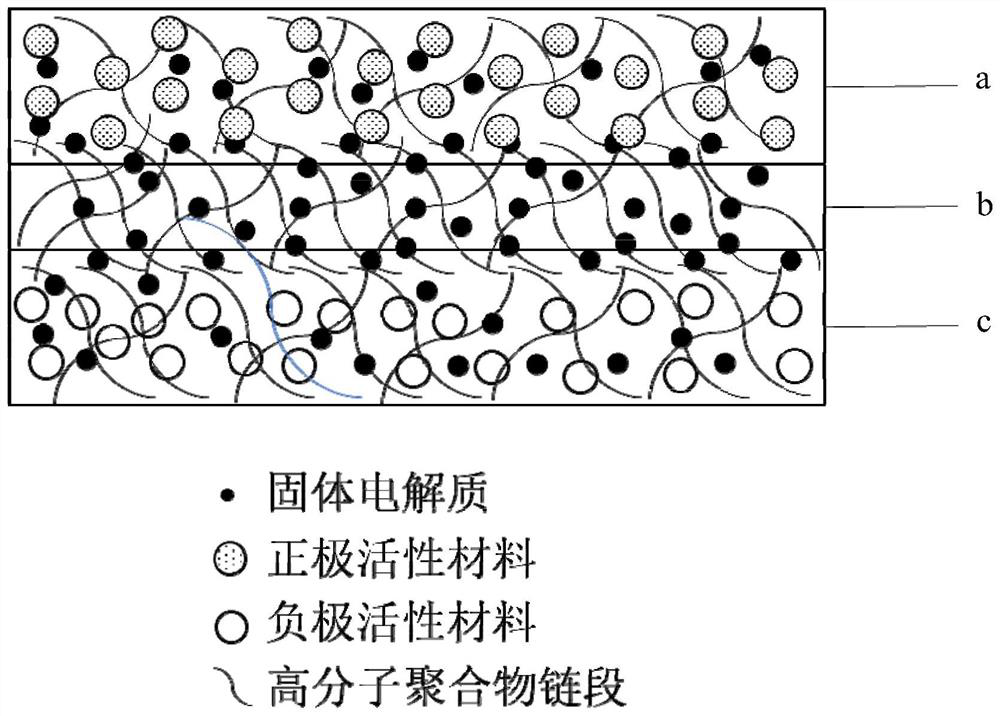

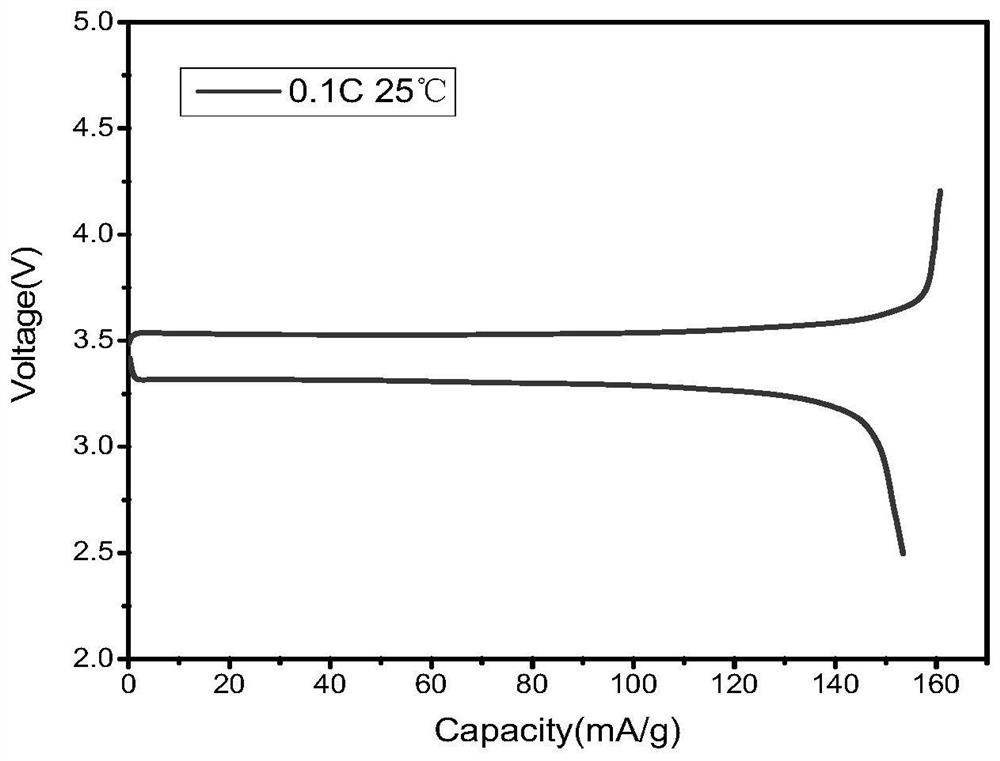

[0047] (1) Preparation of positive electrode slurry: positive active material lithium iron phosphate, conductive agent Super-P, binder PVDF-HFP, solid electrolyte Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 Disperse in NMP (N-methylpyrrolidone) at a mass ratio of 9:0.5:0.4:0.1, stir magnetically for 6 hours, and sonicate for 2 hours to prepare a positive electrode slurry with a solid content of 400 mg / mL;

[0048] (4) Coating the positive electrode slurry on the organic-inorganic composite solid electrolyte (PVDF-HF P / LiTFSI / Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 ) one side of the film, dried in a vacuum oven at 80°C for 12 hours to obtain a metal-free current collector composite positive electrode;

[0049] (5) Preparation of the negative electrode slurry: the negative active material artificial graphite, conductive agent carbon nanotubes, binder PVDF-HFP, solid electrolyte Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 Disperse in NMP (N-methylpyrrolidone) at a mass ratio of 9: 0.5:0.4:0.1, stir ma...

Embodiment 2

[0053] (1) Polish the surface of the metal lithium sheet with a diameter of 15.6 mm and a thickness of 0.45 mm with sandpaper, and then the prepared electrolyte slurry (PEO / LiTFSI / Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 ) uniformly coated on the surface of the lithium sheet, dried to completely evaporate the solvent, and obtain a solid electrolyte composed of metal lithium;

[0054] (2) Preparation of positive electrode slurry: positive active material lithium manganese phosphate, conductive agent graphene, binder PEO, solid electrolyte Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Disperse in DMF (N,N-dimethylformamide) at a mass ratio of 8:1:0.6:0.4, stir magnetically for 6 hours, and sonicate for 1 hour to prepare a positive electrode slurry with a solid content of 450 mg / mL;

[0055] (3) Evenly coat the positive electrode slurry on the organic-inorganic composite solid electrolyte (PEO / LiTFSI / Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 ) on the other side of the film, vacuum drying at 70...

Embodiment 3

[0059] (1) Preparation of positive electrode slurry: the positive active material nickel-cobalt-manganese ternary material, conductive agent Ketjen black, binder PAN, solid electrolyte Li 7 La 3 Zr 2 o 12 Disperse in NMP (N-methylpyrrolidone) at a mass ratio of 8.5:0.7:0.4:0.4, stir magnetically for 6 hours, and sonicate for 3 hours to prepare a positive electrode slurry with a solid content of 480 mg / mL;

[0060] (4) Coating the positive electrode slurry on the polymer solid electrolyte (PAN / LiClO 4 ) side, dried in a vacuum oven at 80°C for 12 hours to obtain a metal-free current collector composite positive electrode;

[0061] (5) Preparation of negative electrode slurry: negative active material carbon fiber, conductive agent carbon black, binder PAN, solid electrolyte Li 7 La 3 Zr 2 o 12 Disperse in NMP (N-methylpyrrolidone) at a mass ratio of 8.5:0.7:0.4:0.4, stir magnetically for 6 hours, and sonicate for 3 hours to prepare a negative electrode slurry with a soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap