Double-barrier deep-nitrogen-charged food fresh-keeping process and fresh-keeping food

A food preservation and food technology, applied in food preservation, food ingredients as antimicrobial preservation, food ingredients, etc., can solve the problems of unpopular food additives, inability to effectively remove oxygen, loss of flavor, etc., to achieve long-term benefits Preservation, not easy to change color, prevent the effect of flavor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

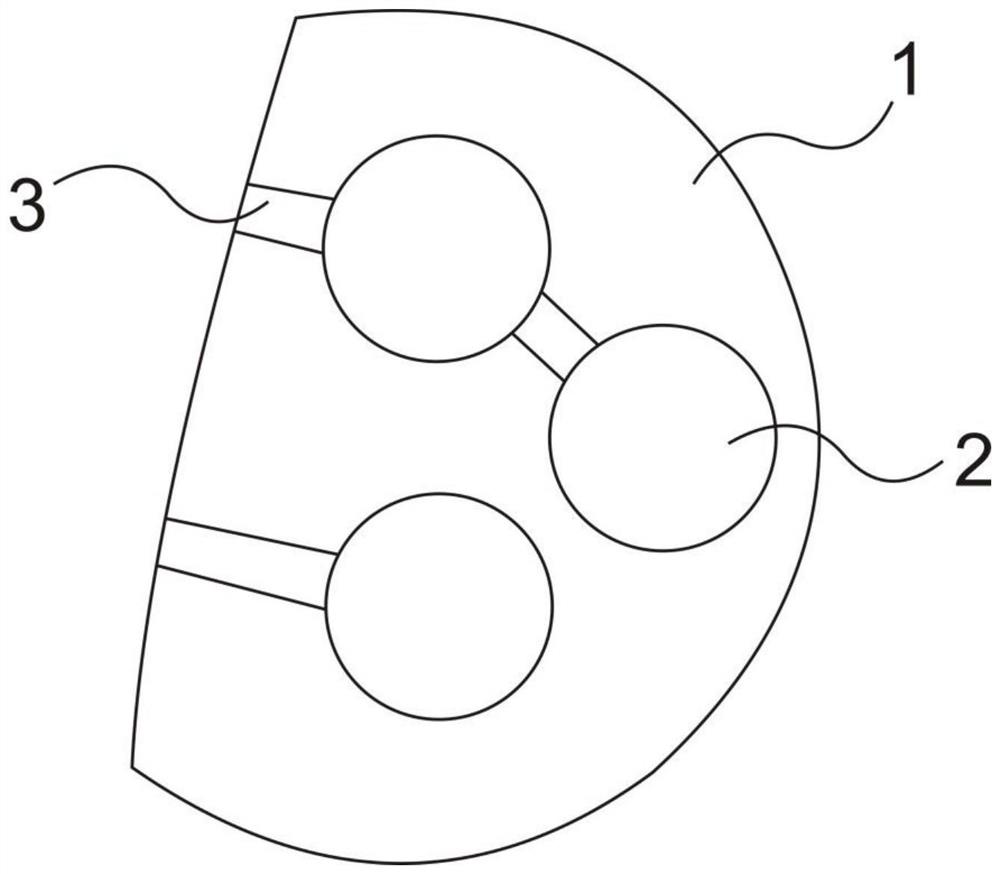

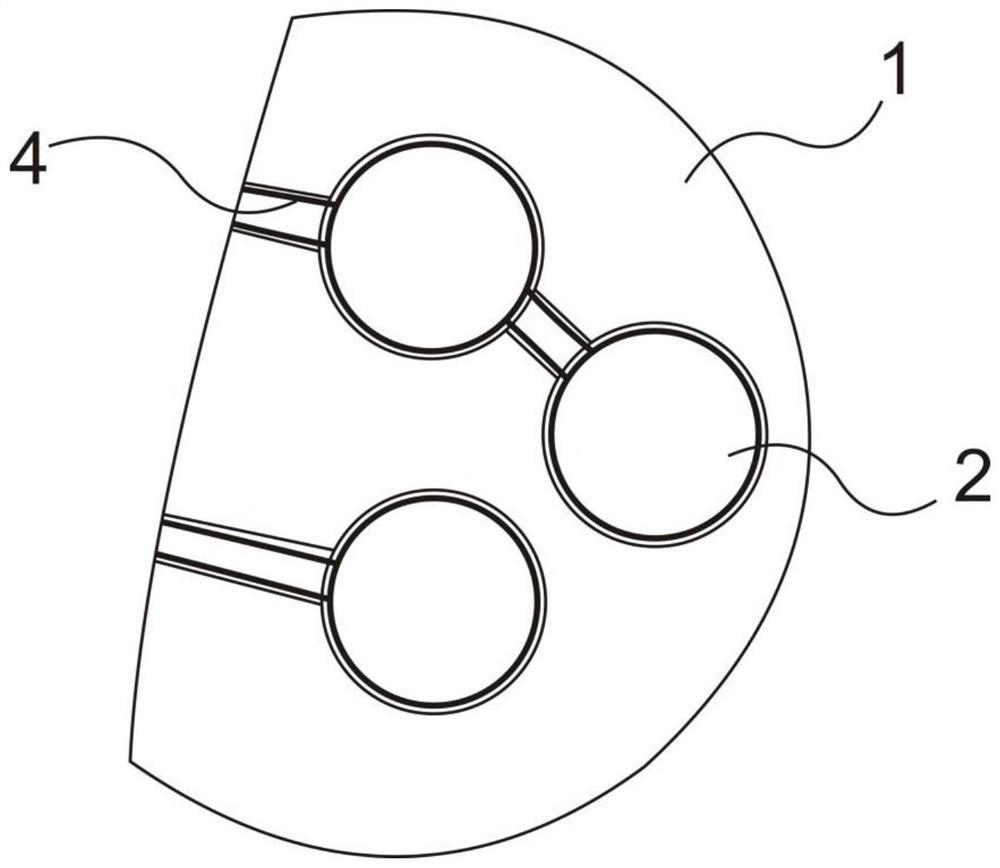

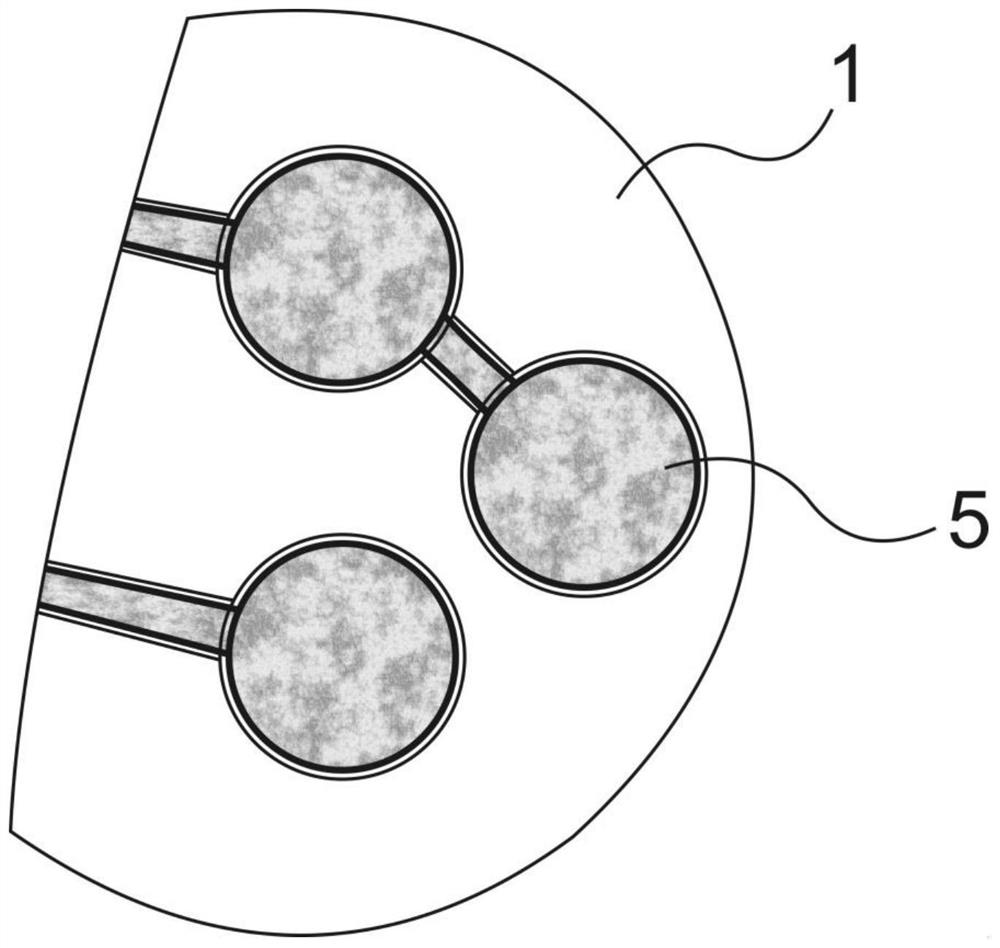

Method used

Image

Examples

Embodiment 1

[0061] A fresh-keeping process for salty cashew nuts filled with nitrogen in a double-barrier depth provided by this embodiment includes:

[0062] Step a, pre-drying the fresh cashew nuts until the moisture content is 8%, so that the internal tissue of the cashew nuts forms pores and air passage structures, and the drying method adopts hot air drying;

[0063] Step b, putting the cashew nuts in step a into a vacuum container for vacuum treatment, the absolute vacuum degree is maintained at 1000 Pa, and the vacuum degree maintenance time is 6 min, so as to extract the air in the cashew nut stomata airway structure;

[0064] Step c. In a vacuum state, add infiltration solution to the vacuum container to immerse the cashew nuts, and keep the immersion time at 6 min. Among them, the composition of the infiltrate includes water, trehalose and probiotics, and the mass ratios are 70%, 29.8%, and 0.2% respectively;

[0065] Step d, the vacuum is broken, the treated cashew nuts return...

Embodiment 2

[0072] The present embodiment provides a fresh-keeping process for double-barrier deep nitrogen-filled chocolate-coated corn kernels, including:

[0073] Step a, pre-drying the fresh corn kernels until the water content is below 5%, so that the internal tissue of the corn forms a stomata airway structure, and the drying method adopts a freeze-drying process;

[0074] Step b, putting the corn kernels in step a into a vacuum container for vacuum treatment, the absolute vacuum degree is maintained at 1200 Pa, and the vacuum degree maintenance time is 7 minutes min, so as to extract the air in the corn kernel stomata airway structure;

[0075] Step c, in a vacuum state, add the infiltration solution to the vacuum container, immerse the corn kernels, and keep the immersion time at 6 minutes; the composition of the infiltration solution includes 60% water by mass ratio, 39.9% trehalose and 0.1% probiotics;

[0076] Step d, breaking the vacuum, the treated corn kernels return to norm...

Embodiment 3

[0083] This embodiment provides a fresh-keeping process for Lipu taro strips with double-barrier deep nitrogen-filled chocolate and batter, including:

[0084] Step a, pre-drying the fresh Lipu taro until the water content is below 5%, so that the internal tissue of the Lipu taro forms a stomata airway structure, and the drying method adopts a freeze-drying process;

[0085] Step b, put the Lipu taro in step a into a vacuum container for vacuum treatment, the absolute vacuum degree is maintained at 900pa, and the vacuum degree maintenance time is 5 minutes, so as to extract the air in the stomata and airway structure of the Lipu taro;

[0086] Step c, in a vacuum state, add the infiltration solution to the vacuum container, immerse the Lipu taro, and keep the immersion time at 5 minutes; the composition of the infiltration solution includes 60% water by mass ratio, 39.9% trehalose and 0.1% probiotics ;

[0087] Step d, breaking the vacuum, the treated Lipu taro returns to nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com