Self-cleaning outdoor water-based nano tin antimony oxide-silicon dioxide/silicon-acrylic composite transparent heat-insulating coating and preparation method thereof

A technology of nano-tin antimony oxide and silicon dioxide, which is applied in the direction of radiation-absorbing coatings and coatings, and can solve the problems of unfavorable long-term exposure to the outdoors, high solid content of slurry, and poor water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

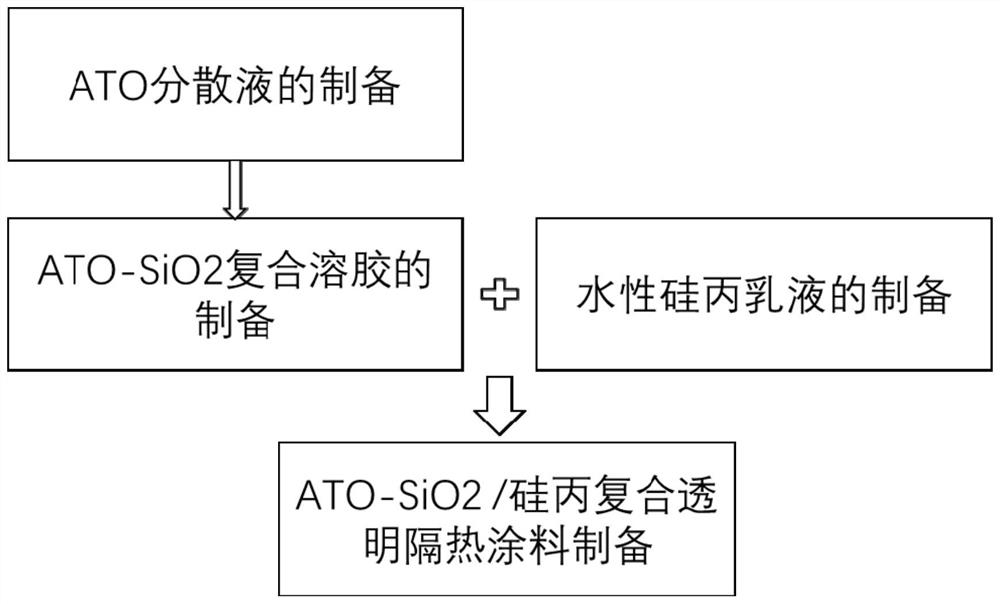

[0048] see figure 1 , the present invention provides an aqueous ATO-SiO 2 / Silicone-acrylic composite transparent heat-insulating paint and preparation method thereof, comprises the steps:

[0049] S101: ATO, dispersant and deionized water are mixed and stirred to prepare an ATO dispersion liquid.

[0050] Further, in step S101, the particle size of ATO is ≤10nm.

[0051] Further, in step S101, the dispersant is a mixture of tertiary amine type dispersant and silane dispersant;

[0052] Further, the tertiary amine type dispersant is selected from one or more of triethanolamine, N,N-dimethylethanolamine, and triethylamine;

[0053] The silane dispersant is selected from one or more of γ-(methacryloyloxy)propyltrimethoxysilane, vinyltrimethoxysilane and vinyltriethoxysilane.

[0054] Further, in step S101, the mass ratio of ATO, dispersant and water is (5-10): (0.2-0.7): (20-30).

[0055] Further, in step S101, ATO is prepared through a hydrothermal method.

[0056] In the...

Embodiment 1

[0097] This embodiment provides a self-cleaning outdoor water-based ATO-SiO 2 / Silicone-acrylic composite transparent heat-insulating coating and preparation method thereof, the steps are as follows:

[0098] (1) Preparation of ATO dispersion

[0099] In terms of parts by mass, 10.0 parts of ATO synthesized by hydrothermal method, 0.1 part of triethanolamine, 0.1 part of vinyltrimethoxysilane and 20 parts of deionized water were ultrasonically dispersed at room temperature for 0.5 hours, and mixed and stirred for 2 to 3 hours. Prepare a homogeneous ATO dispersion.

[0100] (2)ATO-SiO2 2 Preparation of composite sol

[0101] In terms of parts by mass, take 1.0 parts of tetraethyl orthosilicate and dissolve in 20.0 parts of ATO dispersion liquid, then add 0.2 parts of nitric acid aqueous solution with a mass concentration of 10%, mix evenly, and finally add 0.1 parts of 2,4-dihydroxy dihydroxy Benzophenone, stirred for 12 hours, left to age for 24 hours; the whole experiment...

Embodiment 2

[0109] This embodiment provides a self-cleaning outdoor water-based ATO-SiO 2 / Silicone-acrylic composite transparent heat-insulating coating and preparation method thereof, the steps are as follows:

[0110] (1) Preparation of ATO dispersion

[0111] In terms of parts by mass, 10.0 parts of ATO synthesized by hydrothermal method, 0.1 part of triethanolamine, 0.1 part of vinyltrimethoxysilane and 20 parts of deionized water were ultrasonically dispersed at room temperature for 0.5 hours, and mixed and stirred for 2 to 3 hours. Prepare a homogeneous ATO dispersion.

[0112] (2)ATO-SiO2 2 Preparation of composite sol

[0113] In terms of parts by mass, take 1.0 parts of tetraethyl orthosilicate and dissolve in 20.0 parts of ATO dispersion liquid, then add 0.2 parts of nitric acid aqueous solution with a mass concentration of 10%, mix evenly, and finally add 0.1 parts of 2,4-dihydroxy dihydroxy Benzophenone, stirred for 12 hours, left to age for 24 hours; the whole experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com