Platinum complex containing ONCN tetradentate ligand and application of platinum complex in organic light emitting diode

A technology of platinum complexes and tetradentate ligands, which is applied in the field of luminescent materials to achieve good thermal stability, improve luminous efficiency and device life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

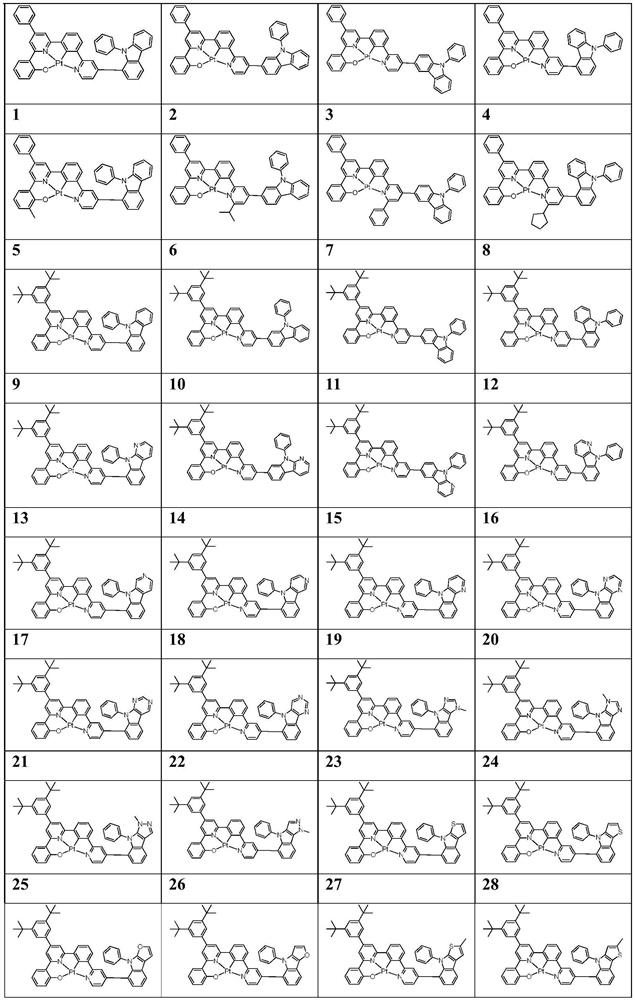

[0049] Synthesis of complex 9

[0050]

[0051] Synthesis of compound 9b:

[0052]1-Bromocarbazole (20g, 81.2mmol), iodobenzene (32g, 162.4mmol), cuprous iodide (1.4g, 8.12mmol), copper powder (0.44g, 8.12mmol), 1,2-cyclohexane Diamine (1.8g, 16.24mmol) and xylene (150ml) were added into the flask, under the protection of nitrogen, the reaction was stirred at 100°C for 12 hours. After the reaction was completed, it was washed twice with toluene (100 mL). The solvent was spun off, and the residue was separated by column chromatography to obtain 6.2 g of a colorless oily product with a yield of 23.7%. 1 H NMR (400MHz, CDCl 3 )δ8.11(d,J=7.7Hz,2H),7.59–7.51(m,4H),7.44(dd,J=7.1,2.3Hz,2H),7.38(d,J=8.2Hz,1H), 7.31(d, J=7.2Hz, 1H), 7.14(t, J=7.7Hz, 1H), 7.07(d, J=8.2Hz, 1H).

[0053] Synthesis of compound 9c:

[0054] Take a 250ml one-mouth bottle, mix 9b (6g, 37.24mmol), 2-methoxypyridine-4-pentanoylboronic acid (10.48g, 44.68mmol), Pd(PPh 3 ) 4 (60mg, 0.52mmol) and potass...

Embodiment 2

[0067] Under a nitrogen atmosphere, weigh about 5.0 mg of a fully dried platinum complex 9 sample, set the heating scan rate to 10°C / min, and the scan range is 25-800°C, and the measured thermal decomposition temperature is 437 (corresponding to 5% thermal weight loss temperature), indicating that complex 9 has very good thermal stability.

Embodiment 3

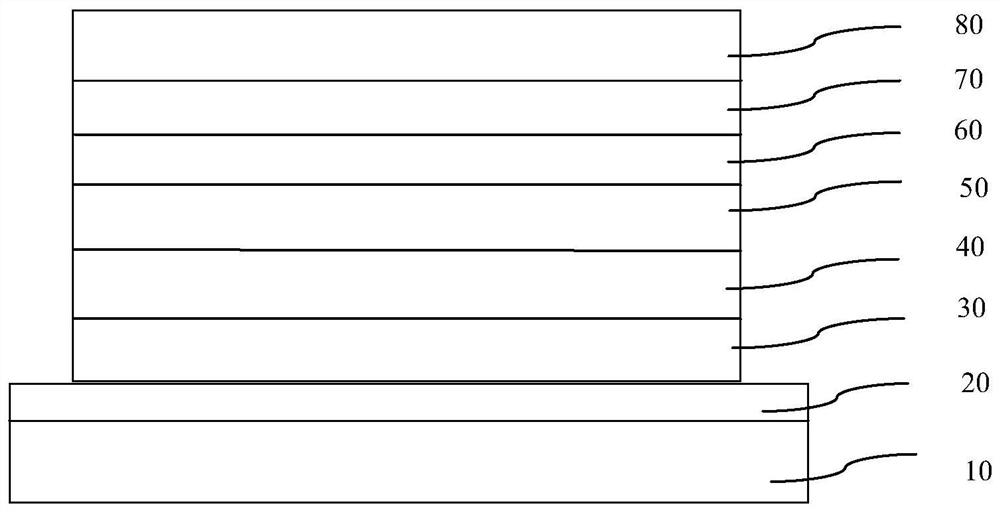

[0069] Organic light-emitting diodes are prepared by using the complex light-emitting material of the present invention. For the device structure, see figure 1 .

[0070] First, the transparent conductive ITO glass substrate 10 (with the anode 20 on it) is sequentially washed with detergent solution, deionized water, ethanol, acetone, and deionized water, and then treated with oxygen plasma for 30 seconds.

[0071] Then, HATCN was vapor-deposited on the ITO to a thickness of 10 nm as the hole injection layer 30 .

[0072] Then, the compound HT was evaporated to form a hole transport layer 40 with a thickness of 40 nm.

[0073] Then, a luminescent layer 50 with a thickness of 20 nm was evaporated on the hole transport layer, and the luminescent layer was composed of platinum complex 9 (20%) mixed with CBP (80%).

[0074] Then, 40nm thick AlQ was evaporated on the light-emitting layer 3 as the electron transport layer 60.

[0075] Finally, 1nm LiF was vapor-deposited as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com