Ternary positive electrode material coated with MoSe2 through vapor deposition and preparation method thereof

A cathode material, vapor deposition technology, applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems of capacity loss, surface structure damage of high nickel materials, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

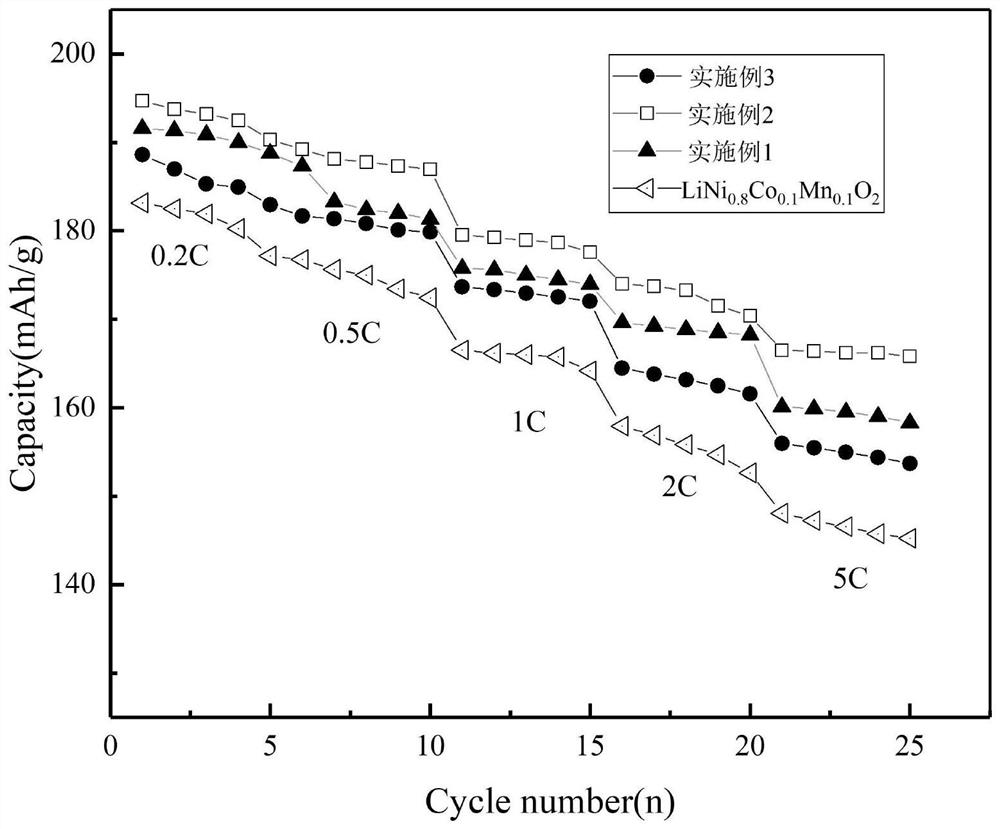

Embodiment 1

[0029] (1) Weigh lithium hydroxide and ternary precursor material (Ni 0.8 co 0.1 mn 0.1 (OH) 2 、Ni 0.6 co 0.2 mn 0.2 (OH) 2 ), mixed ball milling for 30min at a speed of 300r / min, then placed in a tube furnace, fed with oxygen, pre-fired at 480°C for 5h, then kept at 780°C for 14h, and the heating rate was 3°C / min to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material.

[0030] (2) Take 10g of the positive electrode material prepared in the above steps, 0.12g of selenium powder, and 0.11g of molybdenum trioxide powder, mix and grind for 30min, put it into a tube furnace, feed in argon, heat up to 550°C, keep it warm for 6h, and put it in a ternary furnace. Formation of MoSe between material particles 2 gas atmosphere, and then cooled to room temperature, so that molybdenum diselenide is deposited on the surface of the ternary material to obtain MoSe 2 Coated LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6 co 0.2 mn 0.2 o 2 Cathod...

Embodiment 2

[0035] (1) Weigh lithium hydroxide and ternary precursor material (Ni 0.8 co 0.1 mn 0.1 (OH) 2 、Ni 0.6 co 0.2 mn 0.2 (OH) 2 ), mixed ball milling for 30min at a speed of 300r / min, then placed in a tube furnace, fed with oxygen, pre-fired at 480°C for 5h, then kept at 780°C for 14h, and the heating rate was 3°C / min to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6co 0.2 mn 0.2 o 2 Ternary cathode material.

[0036] (2) Take 10g of the positive electrode material prepared in the above steps, 0.24g of selenium powder, and 0.22g of molybdenum trioxide powder, mix and grind for 30min, put it into a tube furnace, feed in argon, heat up to 650°C, keep it warm for 5h, and put it in a ternary furnace. A molybdenum selenide gas atmosphere is formed between the material particles, and then cooled to room temperature, so that molybdenum selenide is deposited on the surface of the material, and finally forms a gas phase coating MoSe 2 LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6 c...

Embodiment 3

[0041] (1) Weigh lithium hydroxide and ternary precursor material (Ni 0.8 co 0.1 mn 0.1 (OH) 2 、Ni 0.6 co 0.2 mn 0.2 (OH) 2 ), mixed ball milling for 30min at a speed of 300r / min, then placed in a tube furnace, fed with oxygen, pre-fired at 480°C for 5h, then kept at 780°C for 14h, and the heating rate was 3°C / min to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material.

[0042] (2) Take 10g of the above materials, 0.48g of selenium powder, and 0.44g of molybdenum trioxide powder, mix and grind for 30 minutes, put them into a tube furnace, pass in argon gas, heat up to 750°C, keep it warm for 5 hours, and place it between the ternary material particles Form a molybdenum selenide gas atmosphere, then cool to room temperature, so that molybdenum selenide is deposited on the surface of the material, and finally form a gas phase coated MoSe 2 LiNi 0.8 co 0.1 mn 0.1 o 2 、LiNi 0.6 co 0.2 mn 0.2 o 2 Material, MoSe 2 The coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com